A kind of rare earth-free mnalcuc permanent magnet alloy and preparation method thereof

A permanent magnet alloy, rare earth-free technology, used in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve problems such as the reduction of saturation magnetization, and achieve improved coercivity, high saturation magnetization, and crystal grains. The effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

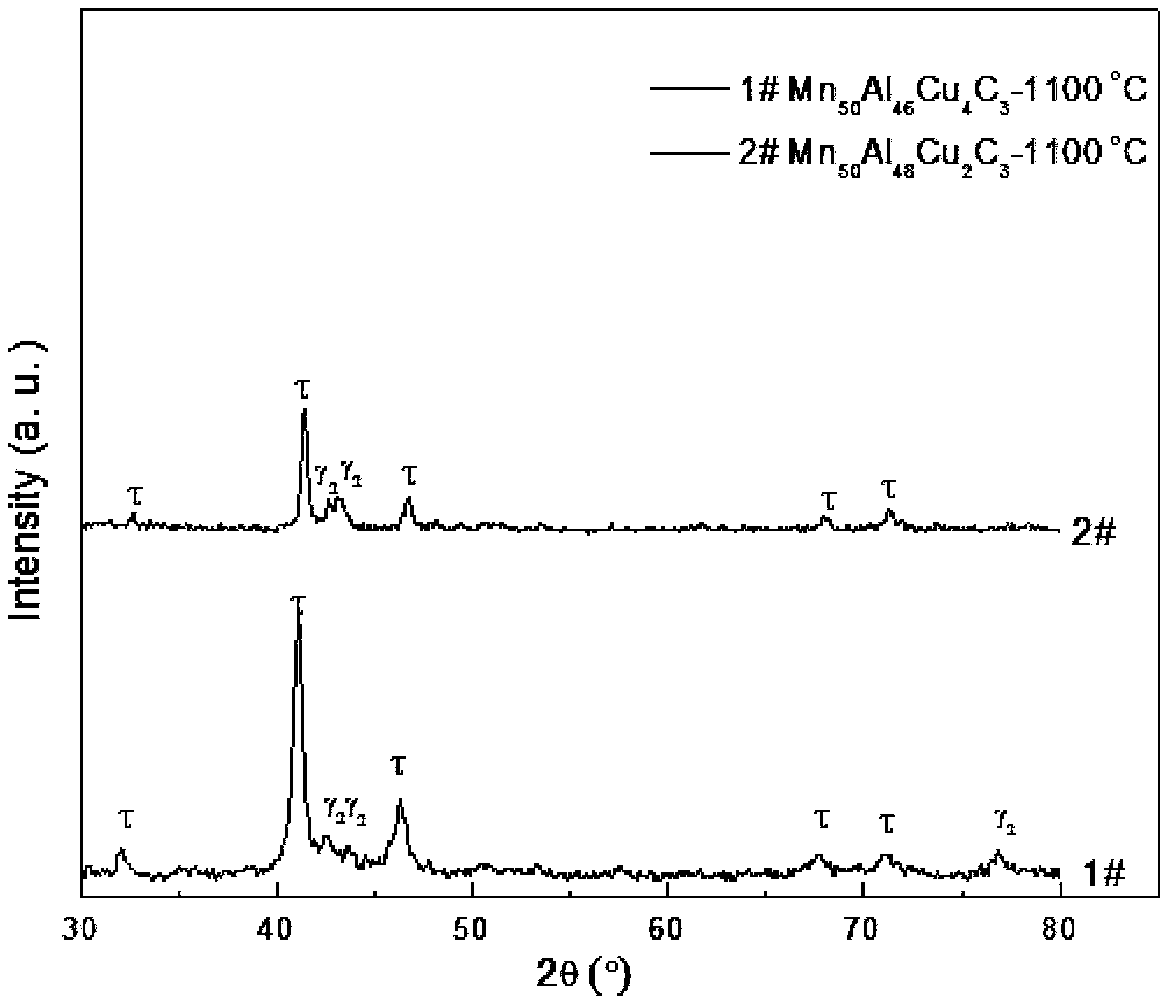

[0043] Example 1-1: Preparation of anisotropic Mn 50 al 46 Cu 4 C 3 flake powder

[0044] (1) The pure manganese block, pure aluminum block, pure copper block and graphite powder with a purity of not less than 99.9% are calculated according to the atomic percentage of Mn 50 al 46 Cu 4 C 3 Weigh the master alloy raw material, because Mn is extremely volatile during smelting, in order to compensate for its volatilization during smelting, add more Mn with a mass percentage of 3% during batching, totaling 3 grams.

[0045] (2) Smelting in a non-consumable vacuum electric arc furnace: put the above-mentioned weighed master alloy raw materials into a copper crucible with circulating cooling water, and fill it with high-purity argon as a protective atmosphere after vacuuming, and heat the alloy repeatedly Melting 3 times to obtain ingot master alloy with uniform composition;

[0046] (3) the ingot obtained above is put into a quartz tube and evacuated to 10 -3 After pa, seal...

Embodiment 1-2

[0049] Example 1-2: Preparation of anisotropic Mn 50 al 46 Cu 4 C 3 flake powder

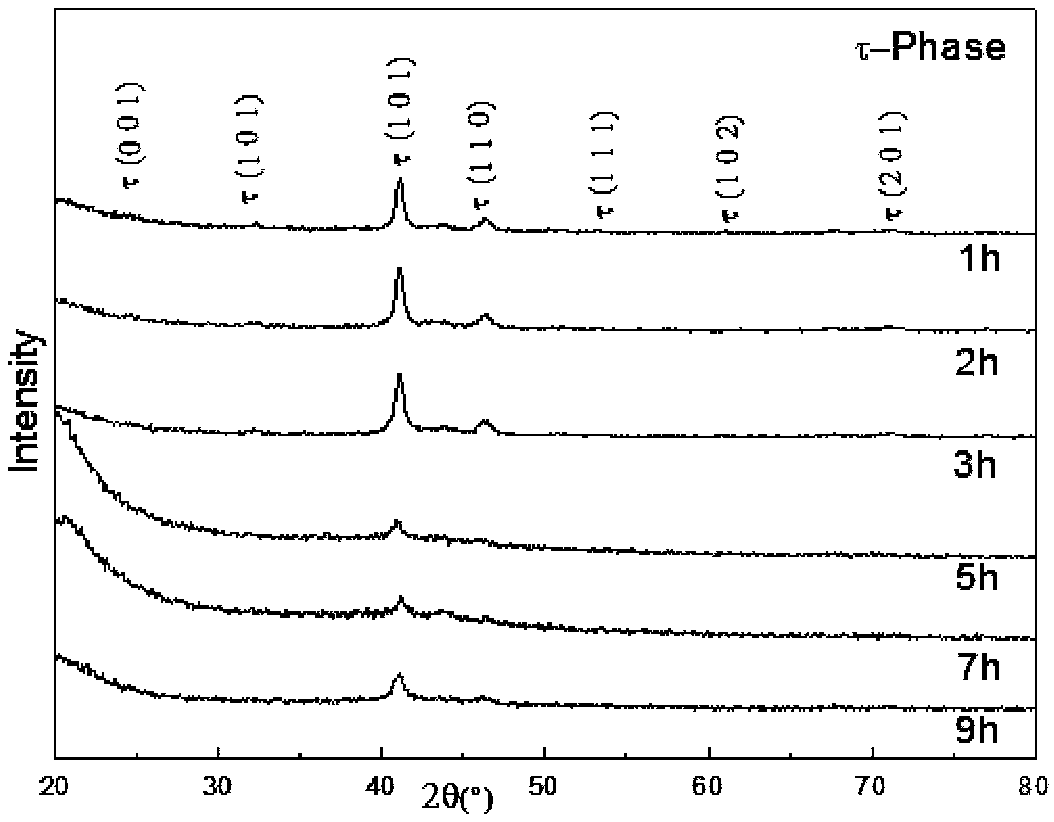

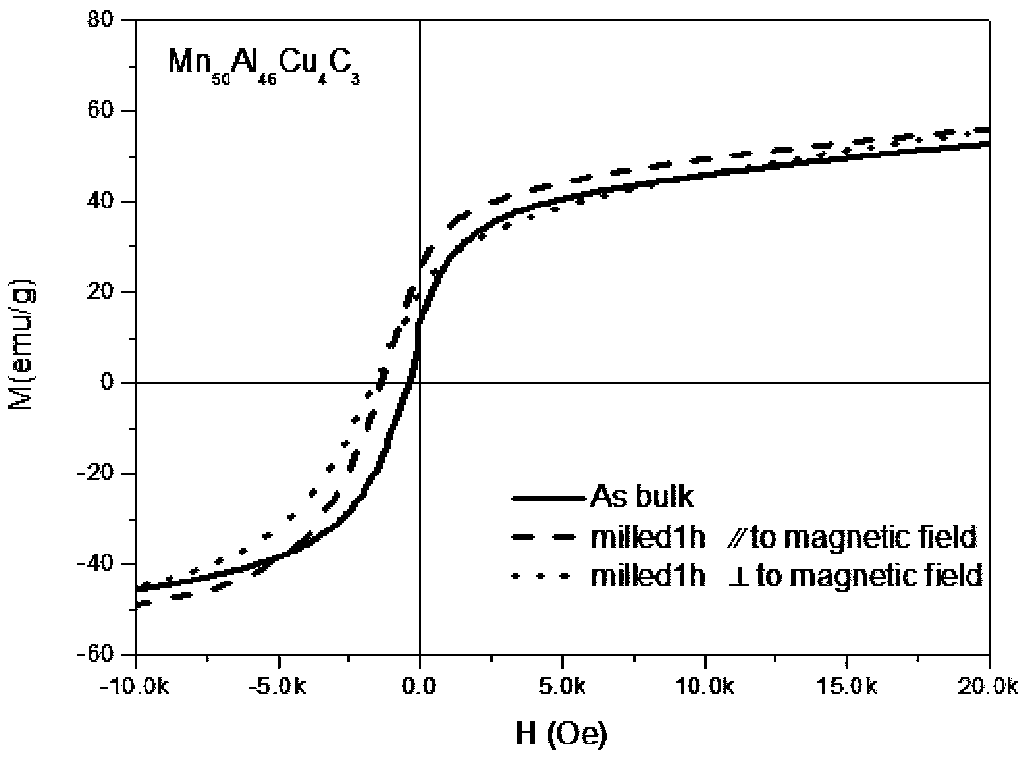

[0050] In step (4), the ball milling time was set to 3 hours, and others were the same as in Example 1. Mn obtained by ball milling for 3 hours 50 al 46 Cu 4 C 3 The XRD pattern of the powder is as figure 2 shown. Magnetic properties such as Figure 5 As shown in a, the powder has obvious magnetic anisotropy.

Embodiment 1-3

[0051] Example 1-3: Preparation of anisotropic Mn 50 al 46 Cu 4 C 3 flake powder

[0052] In step (4), the ball milling time was set to 5 hours, and others were the same as in Example 1. Mn obtained by ball milling for 5 hours 50 al 46 Cu 4 C 3 The morphology of flake powder is shown in Figure 4 As shown in (c,d), the XRD patterns are as follows figure 2 shown. Magnetic properties such as Figure 5 As shown in b, the powder has obvious magnetic anisotropy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com