Method to manufacture improved exciter for an electrical generator

A technology for exciters and generators, which is used in the manufacture of stator/rotor bodies, electromechanical devices, electrical components, etc., and can solve the problems of low permanent magnetic field strength, high cost, and poor magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

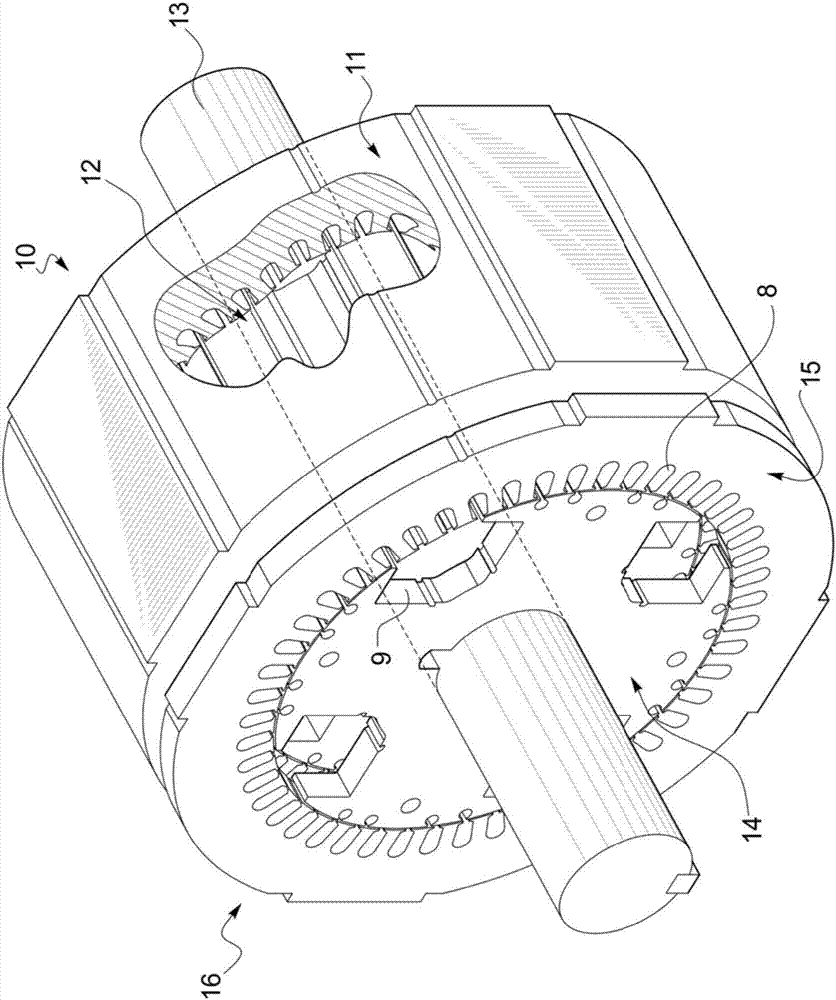

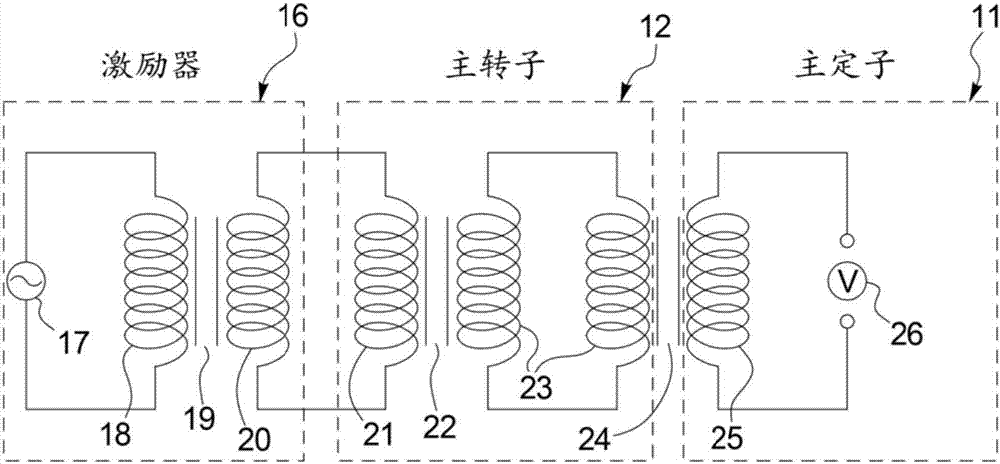

[0058] To facilitate an understanding of the principles of the invention, reference will now be made to the preferred exemplary embodiment / best mode which are illustrated in the drawings and specific language will be used to describe them. It will be understood, however, that no limitation of the scope of the invention is thereby intended and that those skilled in the art to which the invention pertains will appreciate that such modifications and further changes to the illustrated embodiments as well as the illustrated invention are included herein. Such further applications of principles.

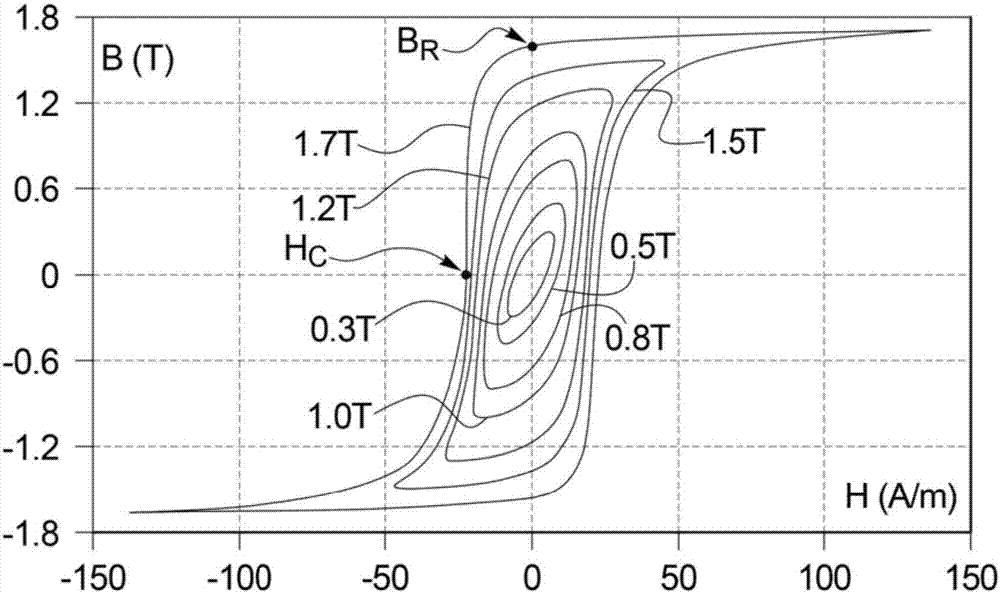

[0059] By the method of the presented exemplary embodiments, improved higher silicon cold-rolled electrical steel (CRES) using semi-machined and fully-machined practices can be used to achieve higher coercivity values than previously achieved using conventional fully hard semi-machined (CRML) grades. High residual magnetism, as measured by coercive force (Hc). In some designs of small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com