Slide ring seal and method for producing a slide ring seal

A slip ring seal, slip ring technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of not allowing relative rotation, complex technology, etc., to reduce weight and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

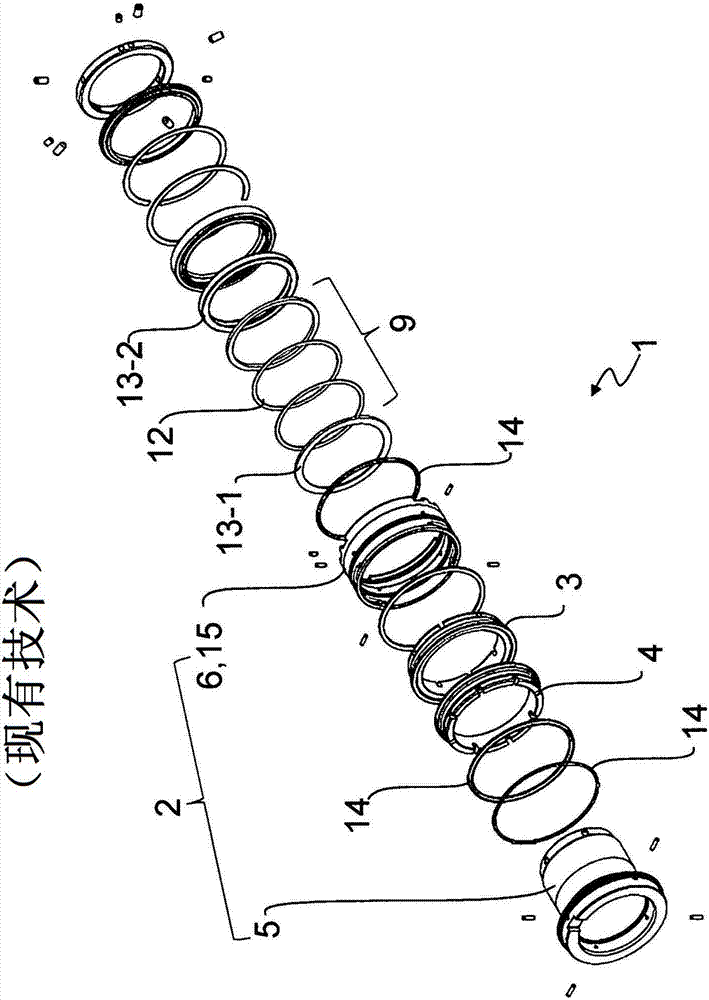

[0028] figure 1An exploded view of the components of a slip ring seal 1 according to the prior art is shown. The slip ring seal 1 has, in particular, a housing part 2 in which a slip ring 4 and a spring-loaded counterpart ring 3 are arranged. The housing assembly 2 comprises a housing element 5 which is designed to move and a housing element 6 which can be fastened in a positionally fixed manner. The movable housing element 5 is also referred to as slip ring seal sleeve, and the stationary fastening housing element 6 is also referred to as slip ring seal housing 15 . In the illustrated embodiment, a movable slip ring 4 is assigned to the movable housing element 5 , while a spring-loaded counterpart ring 3 is assigned to the positionally fixed fastening housing element 6 . In particular, the spring-loaded counterpart ring 3 forms the fixed surface of the slip ring seal 1 , while the slide ring 4 forms the rotatable surface.

[0029] The housing elements 5 , 6 are generally e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com