Fluid conduit element and method for forming fluid conduit element

A technology for fluid conduits and conduit components, applied in the field of components connecting fluid conduit elements and fluid conduit components, can solve problems affecting the performance of fluid conduits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

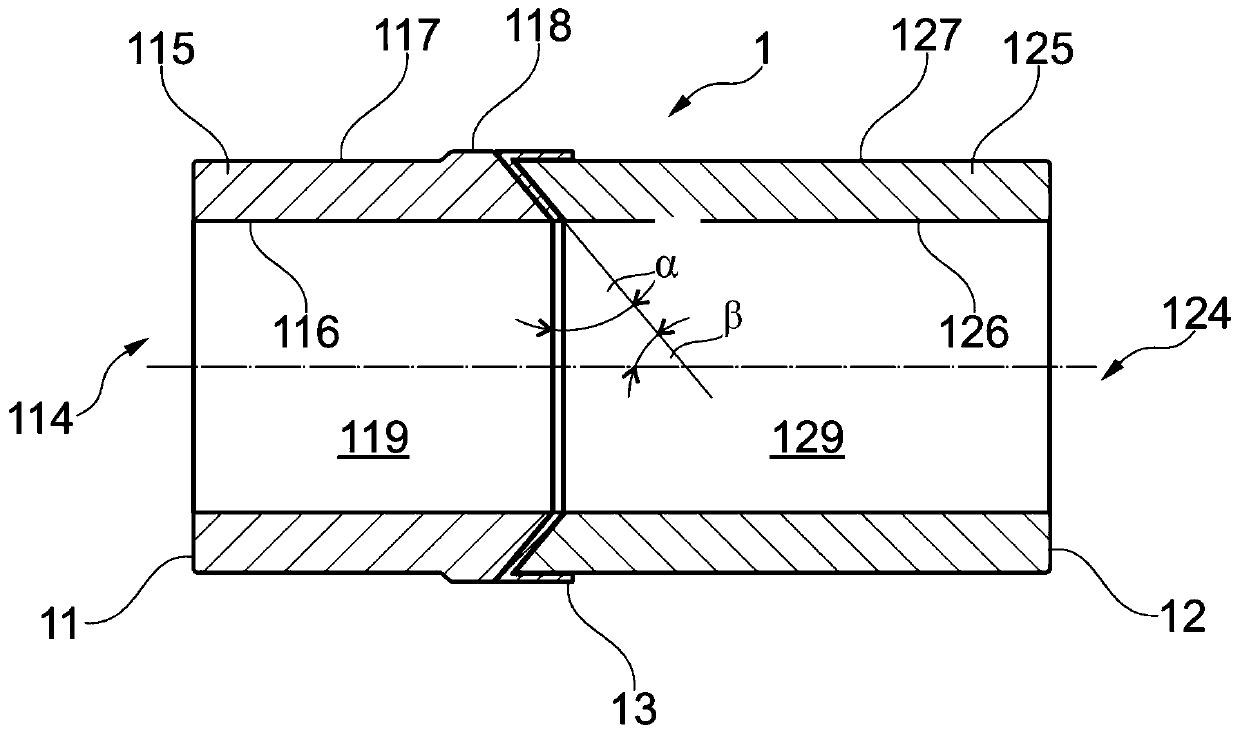

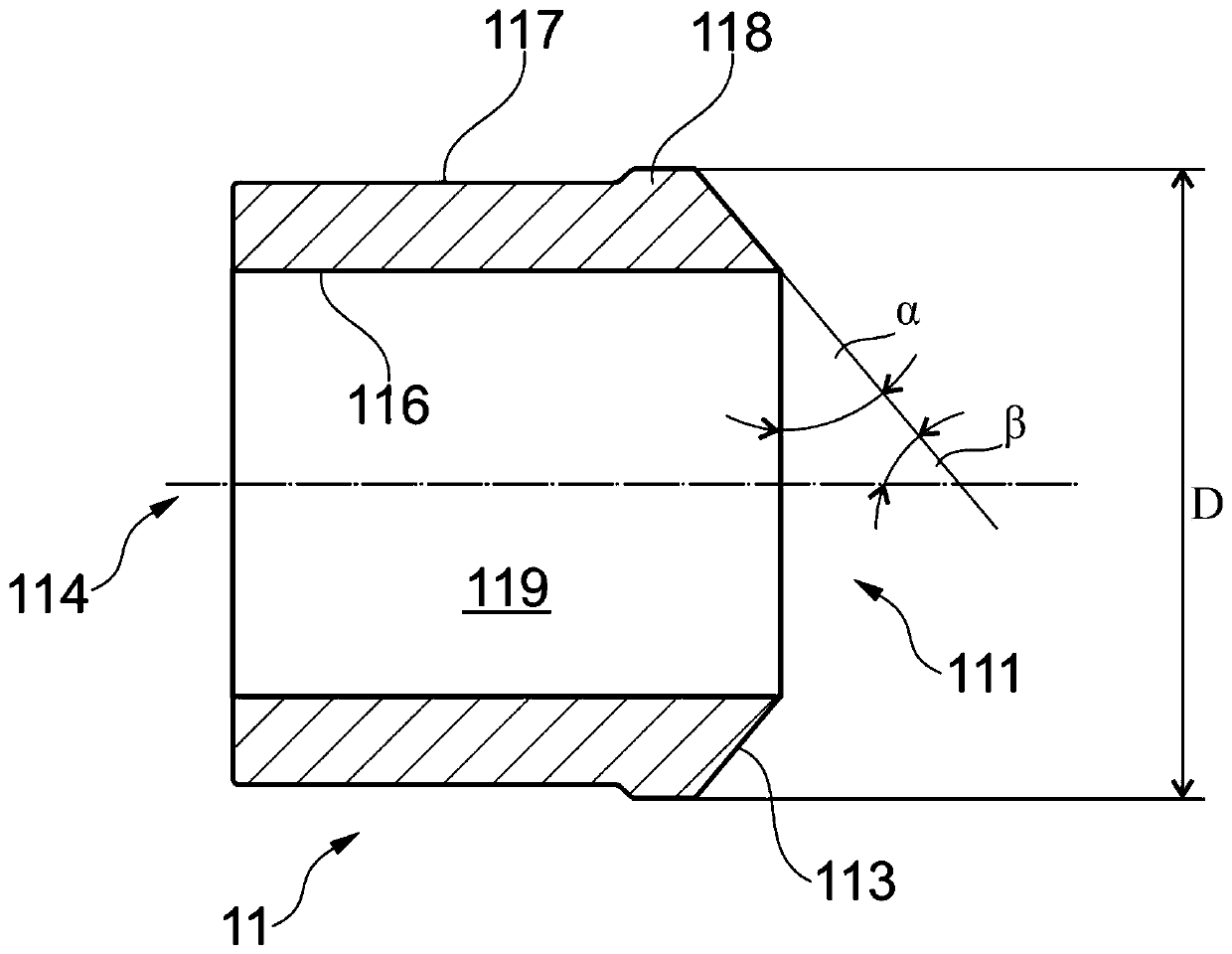

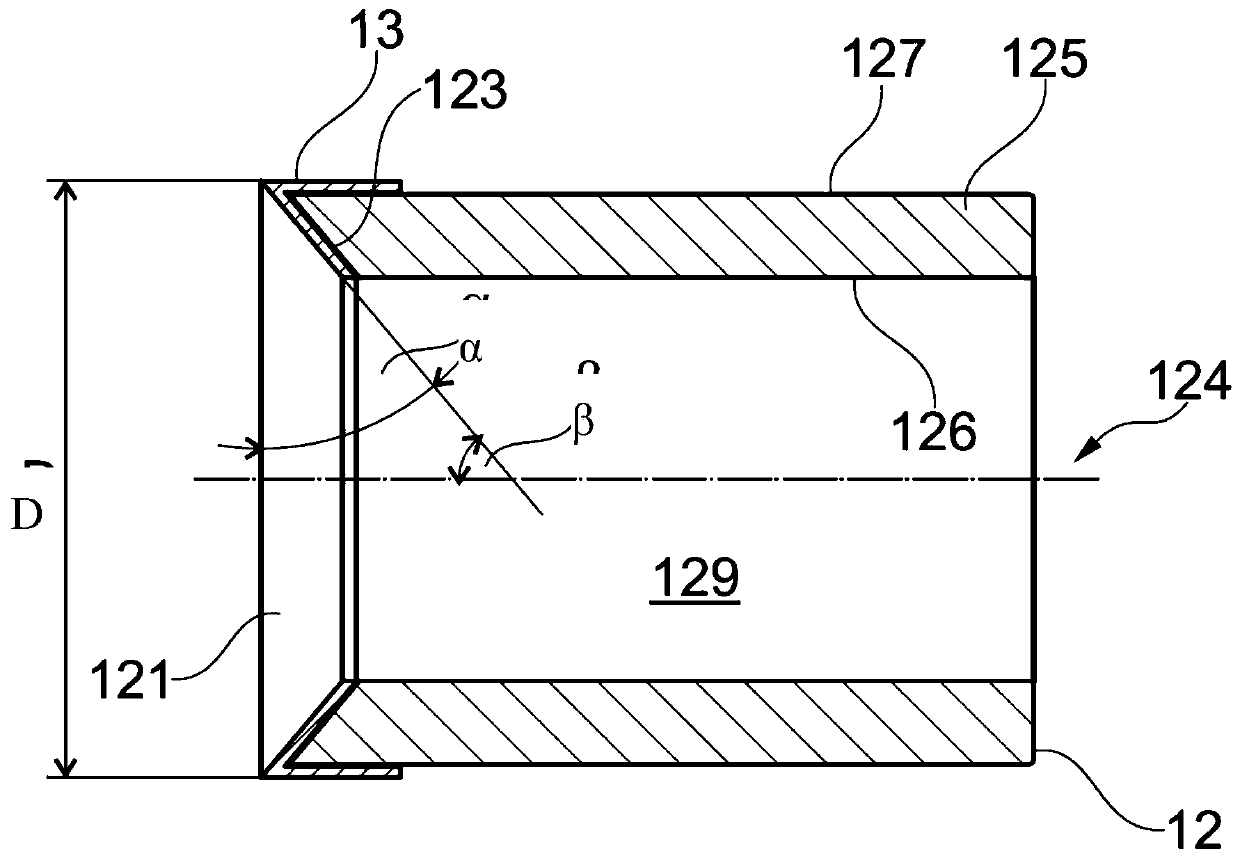

[0040] Exemplary embodiments of the fluid conduit elements or material interface elements disclosed in this specification are further depicted with reference to the accompanying drawings of this summary. Although in this exemplary embodiment the simple fluid conduit member is a tube with circular inner and outer cross-sections for ease of graphical description and understanding, it should be noted that, as noted above, the fluid conduit member may in principle adopt any particular geometry shape. Also the joint surfaces are shown by way of example only and other geometries may be employed within the scope of the claims and without departing from the invention as described and / or claimed herein.

[0041] For a better understanding of the description below, figure 1 A greatly simplified illustration of a fluid conduit member 1 within the scope of the invention is shown. The fluid conduit member basically comprises a first fluid conduit member 11 and a second fluid conduit memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com