Composite material with high corrosion resistance and preparation method thereof

A technology of high corrosion resistance and composite materials, applied in the field of composite materials, can solve problems such as poor corrosion resistance, and achieve the effect of optimized performance, stable performance and tight composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

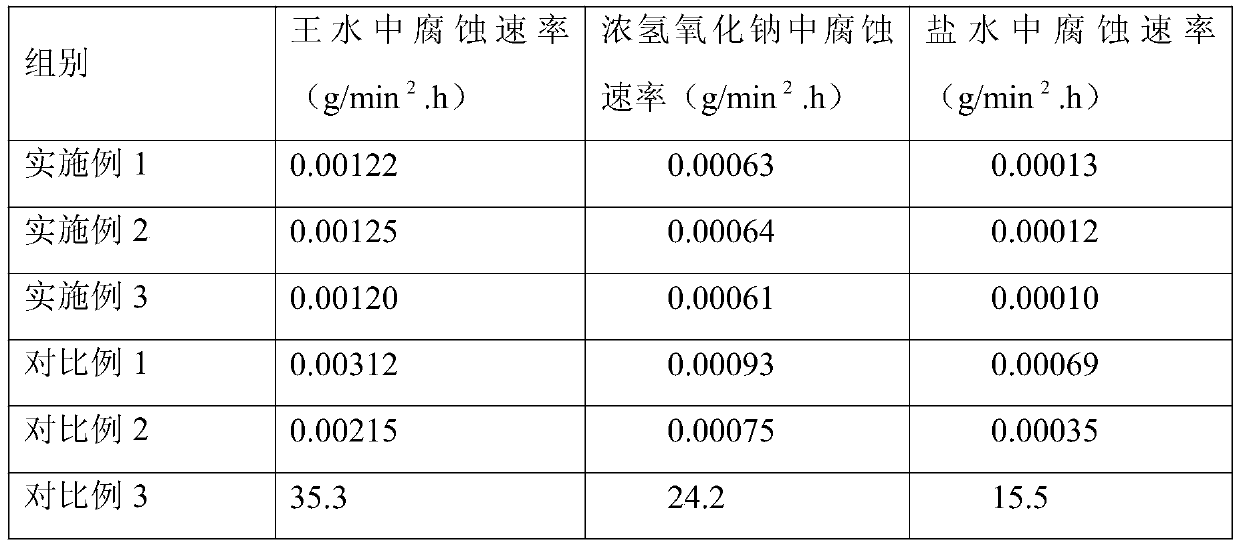

Embodiment 1

[0029] A kind of highly corrosion-resistant composite material of the present embodiment comprises the raw material of following weight portion:

[0030] La 2 o 3 5 parts, Al 2 o 3 5 parts, PbF 2 70 parts, PbO 15 parts, H 3 BO 3 15 servings.

[0031] A method for preparing a highly corrosion-resistant composite material in this embodiment comprises the following steps:

[0032] Step 1, weighing each component raw material as required;

[0033] Step two, the La 2 o 3 、Al 2 o 3 , PbF 2 , PbO, H 3 BO 3 Sequentially add to the mixer and mix first, first stir at a speed of 200r / min for 20min, then stir at a high speed of 650r / min for 35min, stir for 1h until the raw materials are fully mixed, and obtain a mixture A;

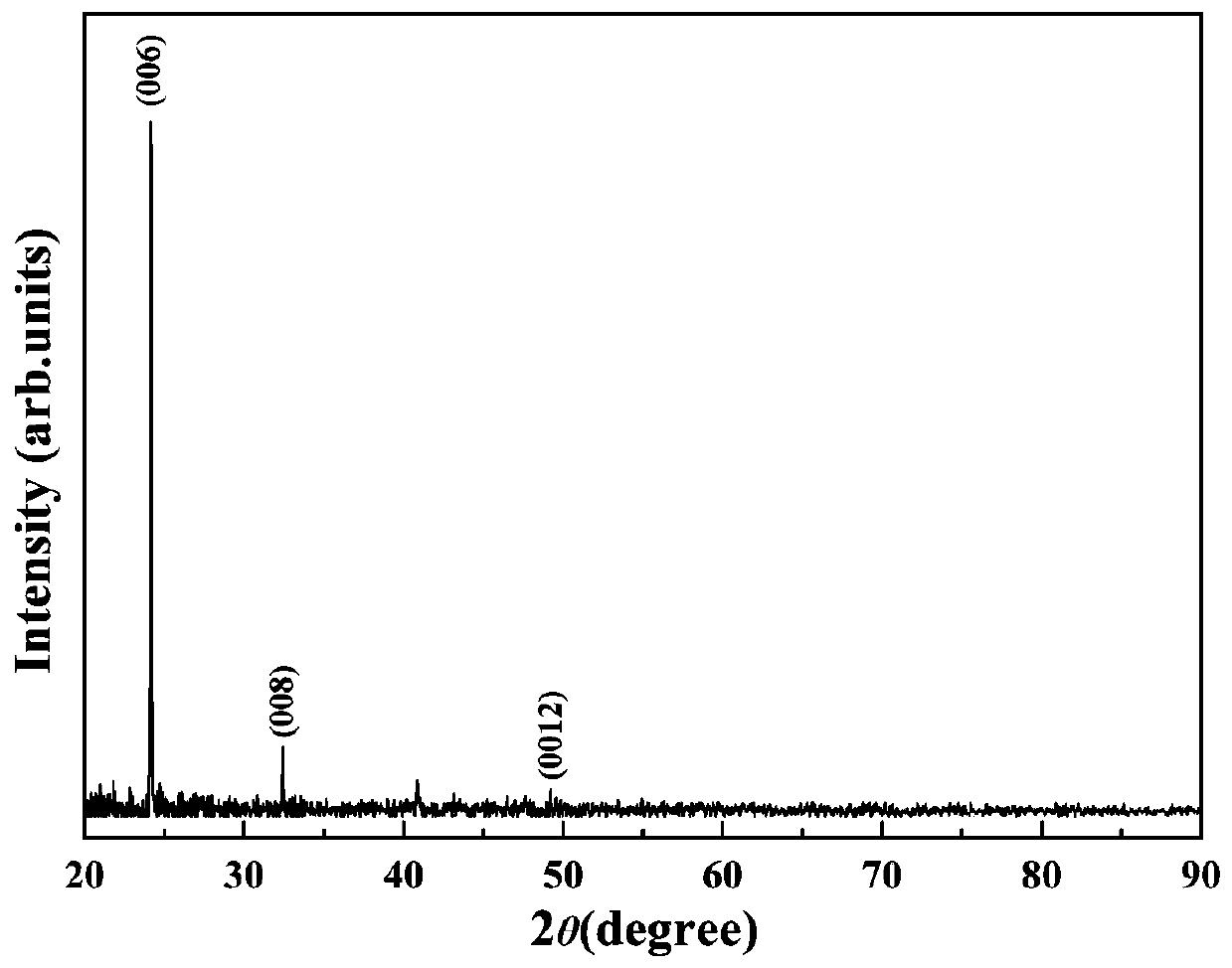

[0034] Step 3, sending the mixed material A in step 2 into a microwave device for microwave radiation treatment, the microwave radiation power is 300W, and the microwave radiation time is 2min, and then ion beam bombardment treatment is used to obta...

Embodiment 2

[0042] A kind of highly corrosion-resistant composite material of the present embodiment comprises the raw material of following weight part:

[0043] La 2 o 3 15 parts, Al 2 o3 15 parts, PbF 2 90 parts, PbO 25 parts, H 3 BO 3 25 servings.

[0044] A method for preparing a highly corrosion-resistant composite material in this embodiment comprises the following steps:

[0045] Step 1, weighing each component raw material as required;

[0046] Step two, the La 2 o 3 、Al 2 o 3 , PbF 2 , PbO, H 3 BO 3 Sequentially add to the blender and mix first, first stir at a speed of 300r / min for 30min, then stir at a high speed of 750r / min for 45min, stir for 2h until the raw materials are fully mixed to obtain a mixture A;

[0047] Step 3, sending the mixed material A in step 2 into a microwave device for microwave radiation treatment, the microwave radiation power is 400W, and the microwave radiation time is 5min, and then ion beam bombardment treatment is used to obtain ...

Embodiment 3

[0055] A kind of highly corrosion-resistant composite material of the present embodiment comprises the raw material of following weight part:

[0056] La 2 o 3 10 parts, Al 2 o 3 10 parts, PbF 2 80 parts, PbO 20 parts, H 3 BO 3 20 servings.

[0057] A method for preparing a highly corrosion-resistant composite material in this embodiment comprises the following steps:

[0058] Step 1, weighing each component raw material as required;

[0059] Step two, the La 2 o 3 、Al 2 o 3 , PbF 2 , PbO, H 3 BO 3 Sequentially add to the mixer and mix first, first stir at a speed of 250r / min for 25min, then stir at a high speed of 700r / min for 40min, stir for 1.5h until the raw materials are fully mixed, and obtain the mixture A;

[0060] Step 3, sending the mixed material A in step 2 into a microwave device for microwave radiation treatment, the microwave radiation power is 350W, and the microwave radiation time is 3.5min, and then the ion beam bombardment treatment is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com