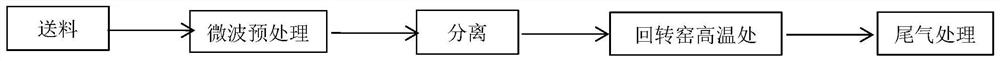

Treatment method of oily sludge

A treatment method and technology for oil sludge, applied in sludge treatment, water/sludge/sewage treatment, oxidation treatment of sludge, etc., can solve problems such as secondary pollution, reduce adhesion and reduce the content of heavy metals , the effect of improving traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A treatment method for oily sludge, carried out according to the following steps:

[0022] Step 1: Microwave pretreatment, use a double screw conveyor to transport the oily sludge material to the microwave treatment tank, and add surfactant, oxidant, sodium hydroxide and water equal to the volume of the material, use microwave heating to 300 ° C, stir For 1 hour, add silicon dioxide and continue stirring so that the mass concentration of silicon dioxide is 2 g / L, continue stirring and heating for 30 minutes, and carry out the reaction.

[0023] Wherein surfactant is the mixture that fatty acid sorbitan and NP-10 are formed by mass ratio as 1:2, and oxidizing agent is the mixture that potassium persulfate and hydrogen peroxide are formed by mass ratio that is 1:1, by mass parts ratio tensio-active agent: Oxidant: silicon dioxide: sodium hydroxide: oily sludge=1:0.5:2:3:10.

[0024] Step 2: Separation. Put the reacted materials in the microwave treatment tank through the...

Embodiment 2

[0028] A treatment method for oily sludge, carried out according to the following steps:

[0029] Step 1: Microwave pretreatment, use a double screw conveyor to transport the oily sludge material to the microwave treatment tank, and add surfactant, oxidant, sodium hydroxide and water equal to the volume of the material, use microwave heating to 300 ° C, stir After 1 hour, add silicon dioxide and continue to stir, and heat for 30 minutes to carry out the reaction.

[0030] Wherein surfactant is the mixture that fatty acid sorbitan and NP-10 are formed by mass ratio as 1:2, and oxidizing agent is the mixture that potassium persulfate and hydrogen peroxide are formed by mass ratio that is 1:1, by mass parts ratio tensio-active agent: Oxidant: silicon dioxide: sodium hydroxide: oily sludge=1.3:0.6:2.2:3.5:12.

[0031] Step 2: Separation. Put the reacted materials in the microwave treatment tank through the separation tank to stand still, separate the oil-water layer and the sedim...

Embodiment 3

[0035] A treatment method for oily sludge, carried out according to the following steps:

[0036] Step 1: Microwave pretreatment, use a double-screw conveyor to transport the oily sludge material to the microwave treatment tank, and add surfactant, oxidant, sodium hydroxide and water equal to the volume of the material, use microwave heating to 300 ° C, stir For 1 hour, add silicon dioxide and continue stirring so that the mass concentration of silicon dioxide is 2 g / L, continue stirring and heating for 30 minutes, and carry out the reaction.

[0037] Wherein surfactant is the mixture that fatty acid sorbitan and NP-10 are formed by mass ratio as 1:2, and oxidizing agent is the mixture that potassium persulfate and hydrogen peroxide form by mass ratio that is 1:1, by mass parts ratio tensio-active agent: Oxidant: silicon dioxide: sodium hydroxide: oily sludge=1.6:0.7:2.6:4:13.

[0038] Step 2: Separation. Put the reacted materials in the microwave treatment tank through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com