Heat transferring compensating element and electrically operatabla vehicle having such a compensating element

A technology for compensating components and transferring heat, applied in electrical components, heat transfer modification, circuits, etc., can solve problems such as poor thermal conductivity, and achieve effective and reliable heat removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

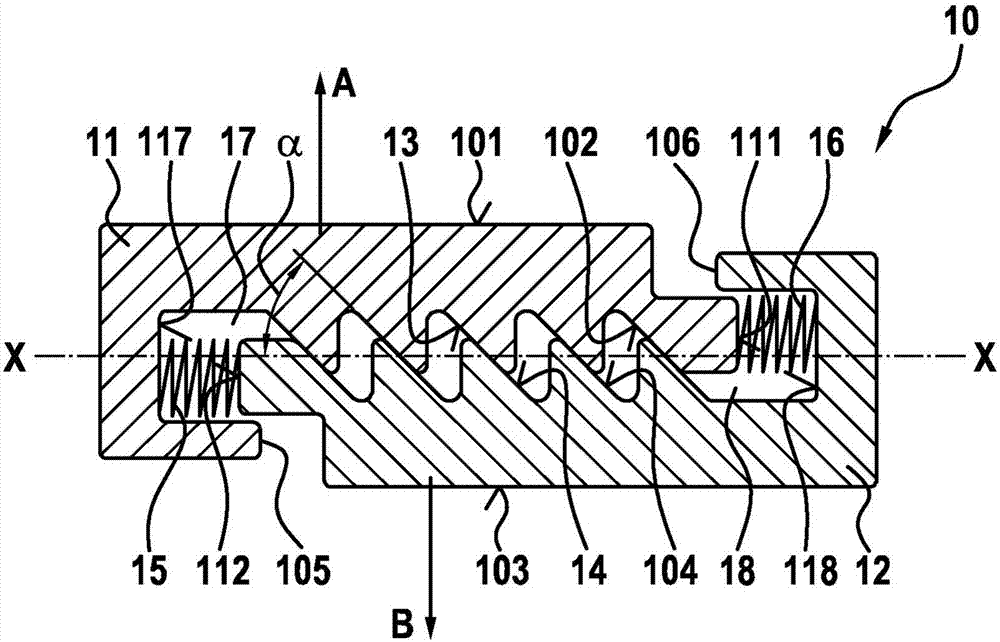

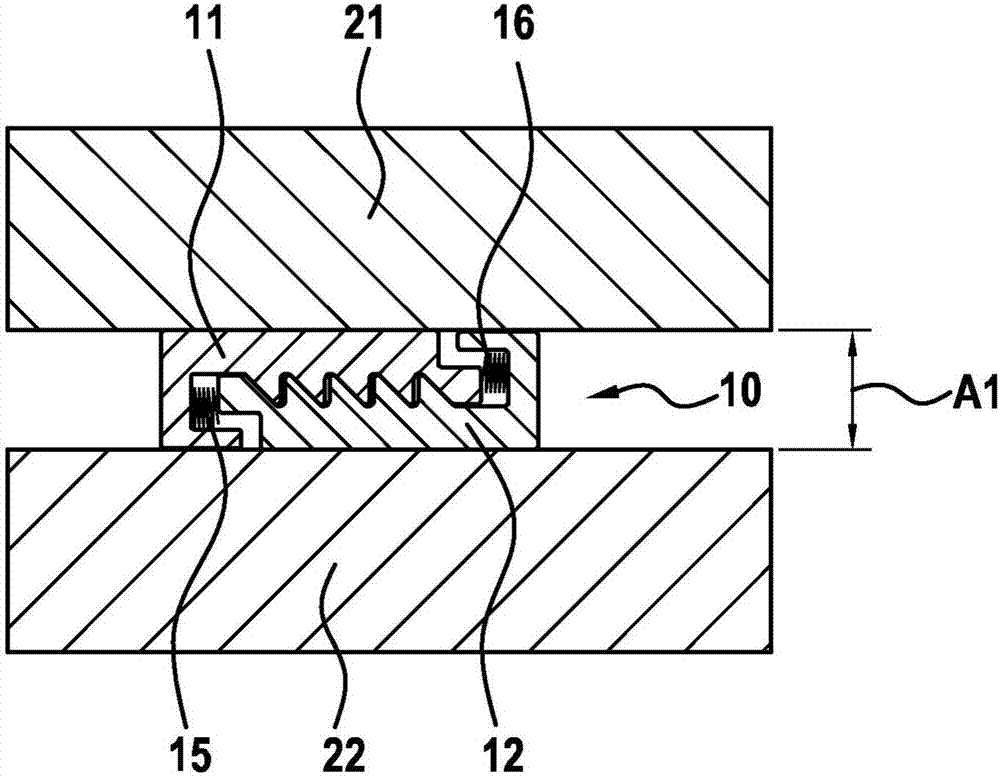

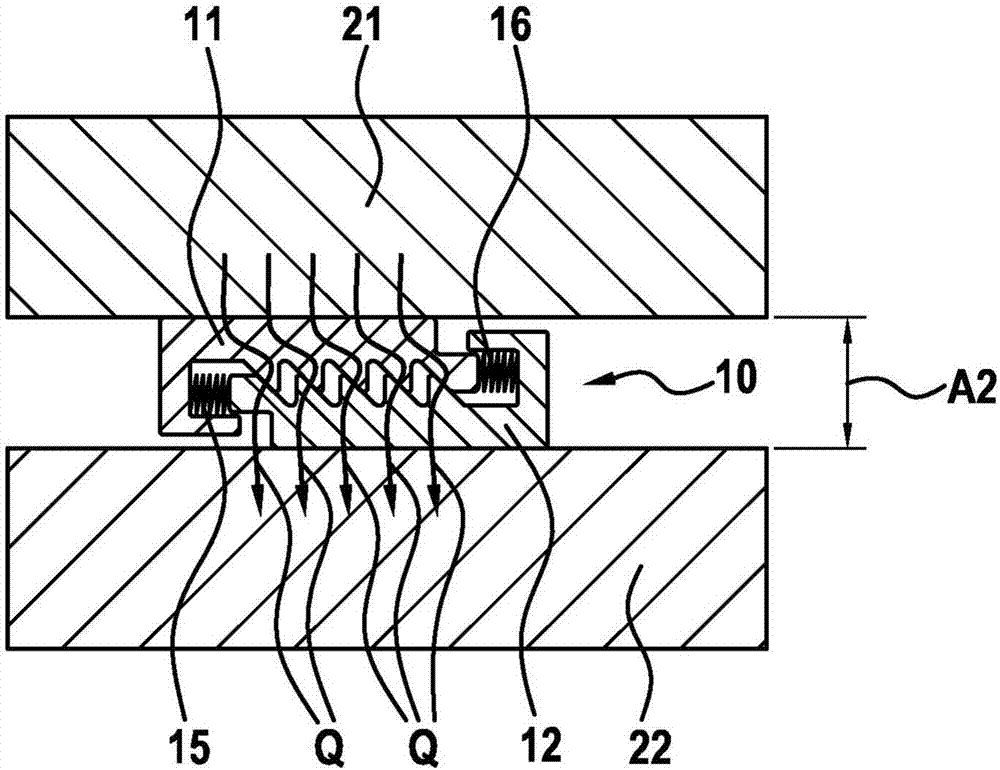

[0025] Refer to the attached Figures 1 to 3 The heat transfer compensating element 10 according to the first embodiment of the present invention will be described in detail.

[0026] The compensation element 10 includes a first heat conducting element 11 and a second heat conducting element 12 . The two heat-conducting elements 11 , 12 are designed identically and can be inserted into one another laterally.

[0027] as by figure 1 It can be seen that the first heat conduction element 11 has a plurality of first inclined planes 13 , and the second heat conduction element 12 has a plurality of second inclined planes 14 . The first heat conducting element 11 has a first contact surface 101 and a second contact surface 102 . Here, the second contact surface 102 includes an inclined plane 13 . In this embodiment a plurality of inclined planes 13 are provided. The second heat conduction element 12 includes a third contact surface 103 and a fourth contact surface 104 .

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com