Plot seed sowing device

A technology of seeding device and community, which is applied in the directions of sowing, sowing seeder, seeder parts, etc., can solve the problems of long preparation work, error-prone, labor-intensive, etc., so as to improve the service life, reduce wear and vibration, and improve seeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention.

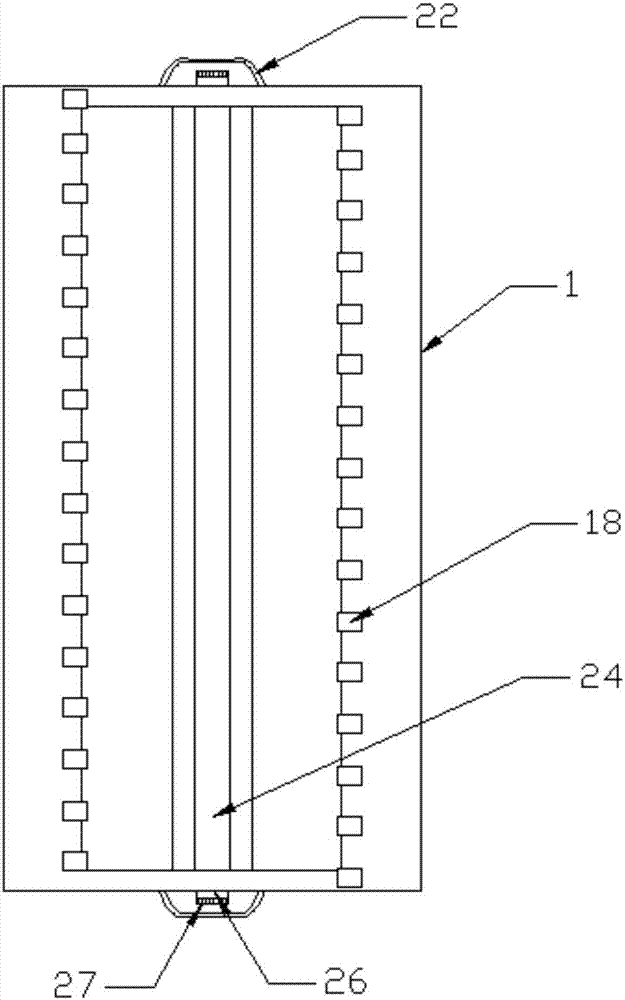

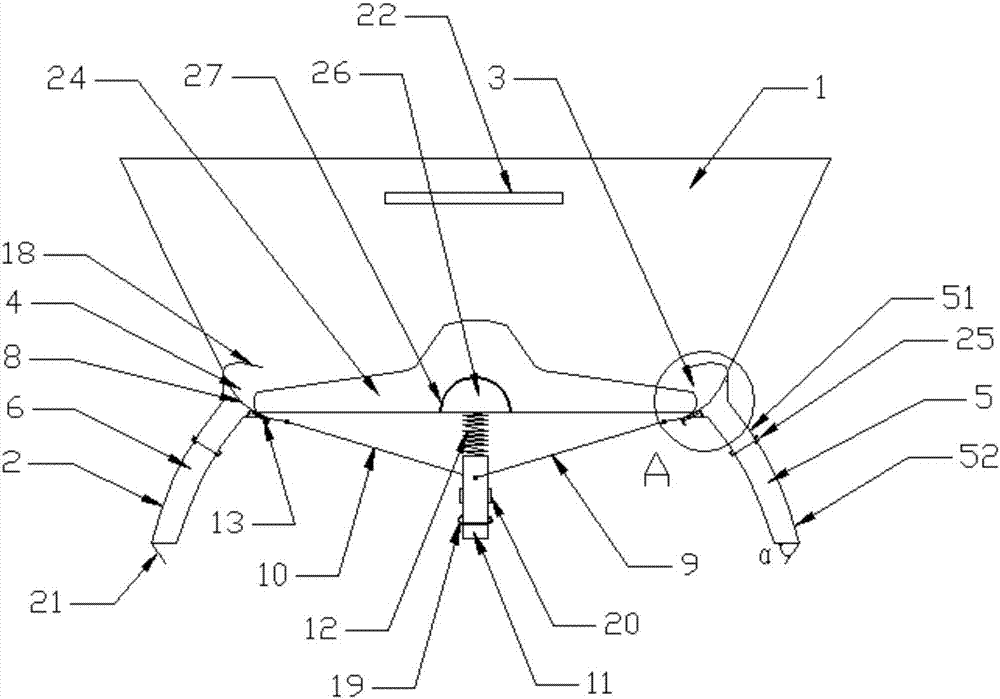

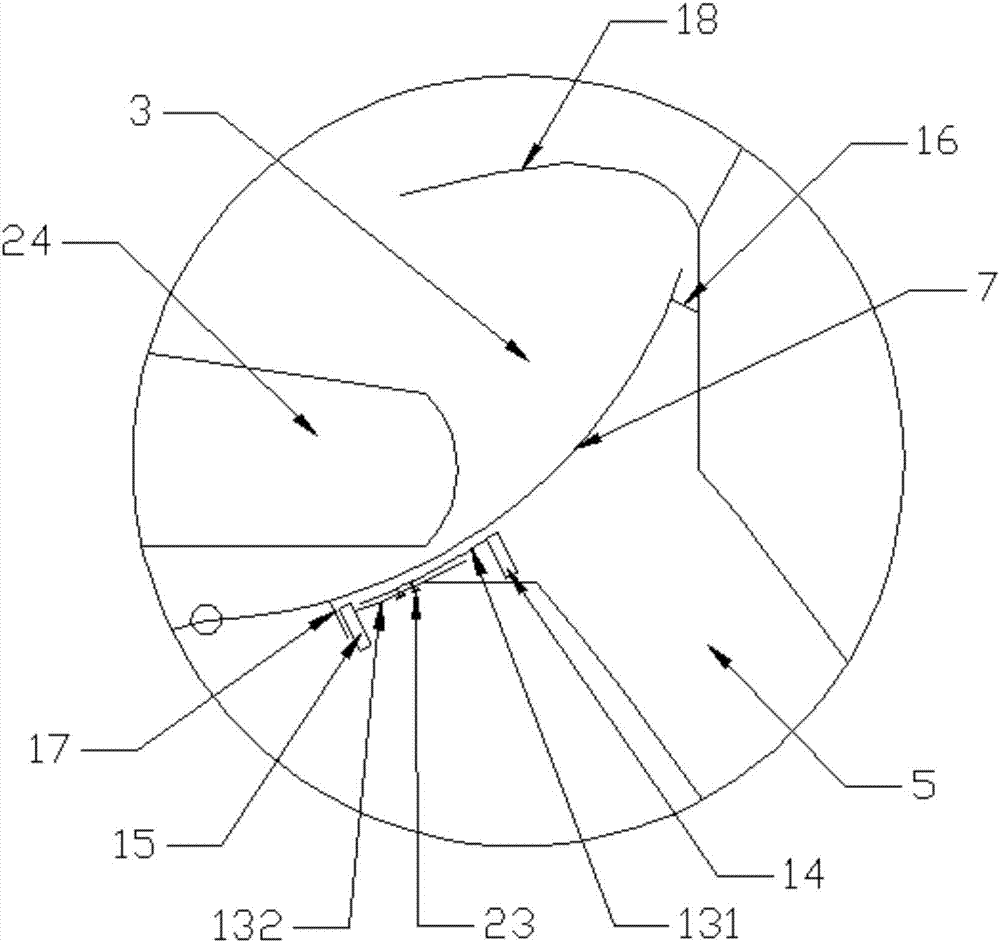

[0025] Such as Figure 1-3 As shown, a plot sowing device comprises a seed tank 1 and a seed tube 2, the bottoms of the two sides of the seed tank 1 are respectively provided with a first seed hole 3 and a second seed hole 4, and are connected with the first hole respectively. The seed hole 3 and the second seed hole 4 match the first seed tube 5 and the second seed tube 6 . A first arc-shaped stopper 7 is provided between the first seed-setting hole 3 and the first seed-setting cylinder 5, and a second arc-shaped stopper is provided between the second seed-setting hole 4 and the second seed-setting cylinder 6 8. Both the first arc-shaped catch 7 and the second arc-shaped catch 8 extend to the bottom of the seed tank 1 and are respectively hinged with the first connecting rod 9 and the second connecting rod 10, and the first connecting rod 9 and the second connecting rod The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com