Bottle wall expansion die for stainless steel water bottle

A stainless steel and stainless steel tube technology is applied in the field of bottle wall expansion molds for stainless steel water bottles to achieve the effects of simple and convenient operation, good expansion effect and not easy to tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

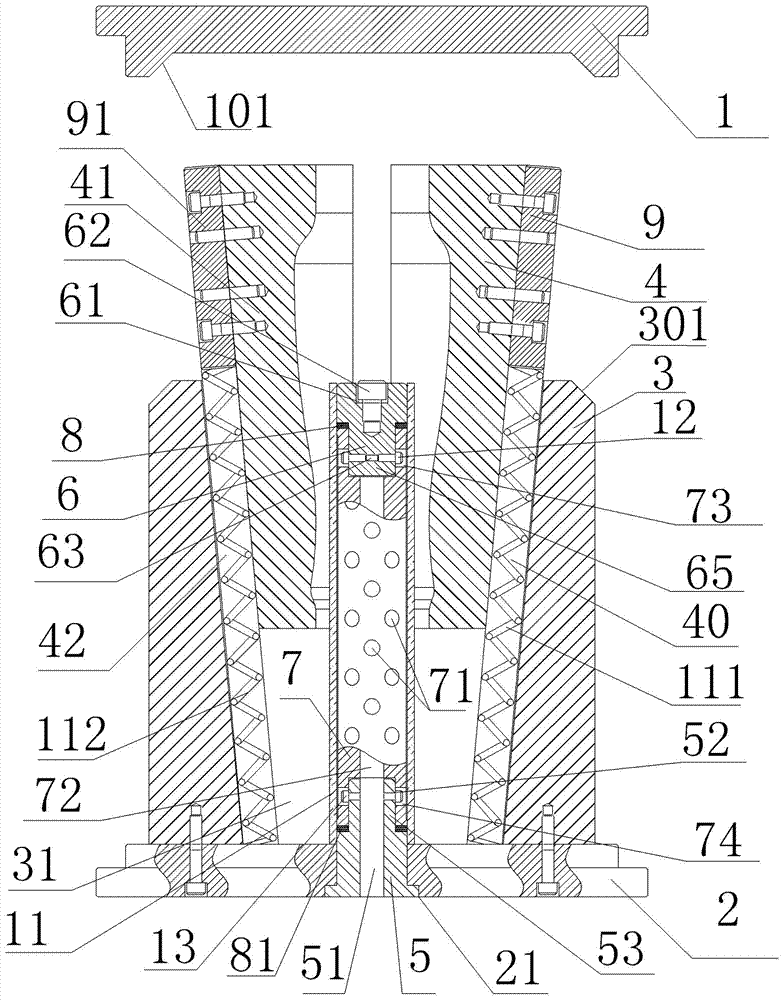

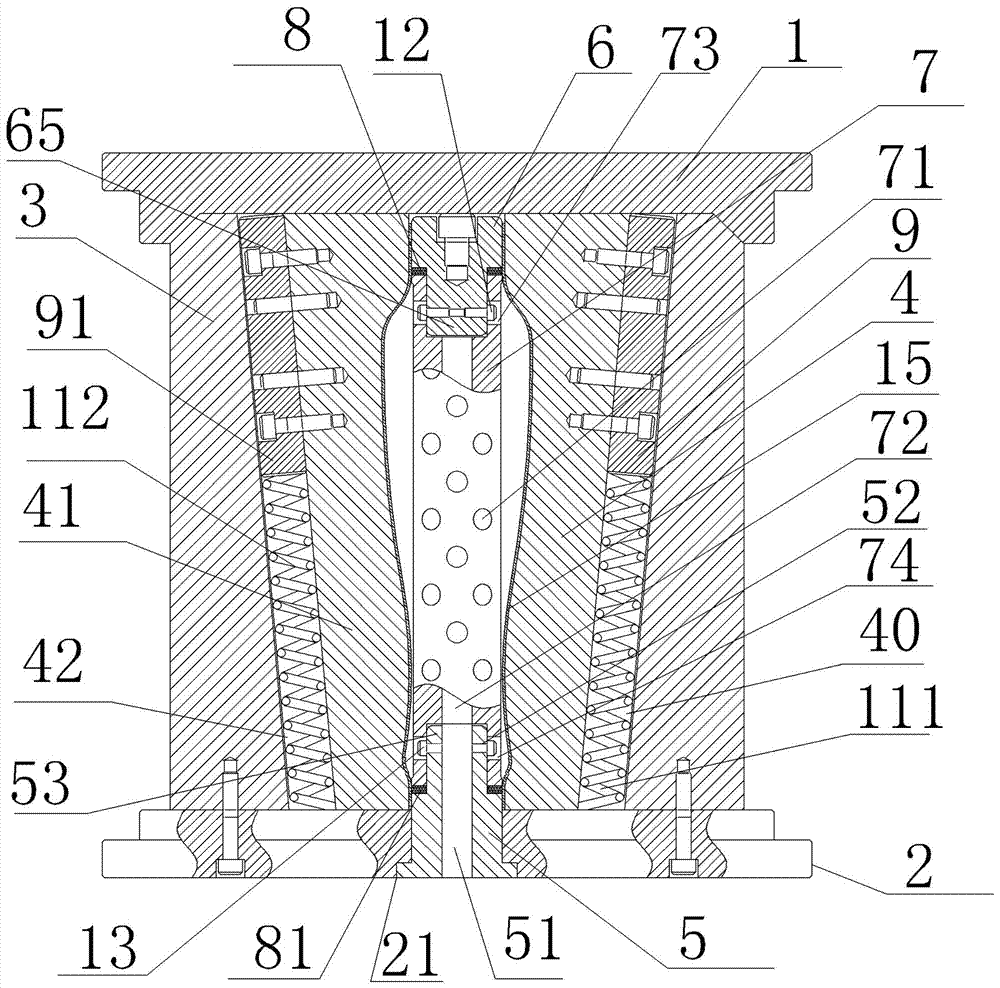

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0015] Such as figure 1 , figure 2 As shown, the bottle wall expansion mold of the stainless steel water bottle described in this embodiment includes: an upper cover plate 1 and a lower mold bottom plate 2, a mold base 3 is fixed on the lower mold base plate 2, and a vertical through-hole is arranged in the mold base 3. The mold base 3 and the trumpet-shaped mold base through-hole 31 with a large diameter and a small diameter, are symmetrically arranged in the mold base through-hole 31 with two supporting molds 4, 41 that can move up and down along the side walls of the mold base through-hole 31, When the branch forming dies 4, 41 moved downward until their lower ends abutted against the bottom plate 2, the branch forming dies 4, 41 were in the clamping position, and now the inner walls of all the branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com