Rolling mechanism and attaching equipment

A technology of rolling and adjusting mechanism, applied in mechanical equipment, material gluing, connecting components, etc., can solve problems such as unsatisfactory rolling effect, achieve the effect of good versatility and improve rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

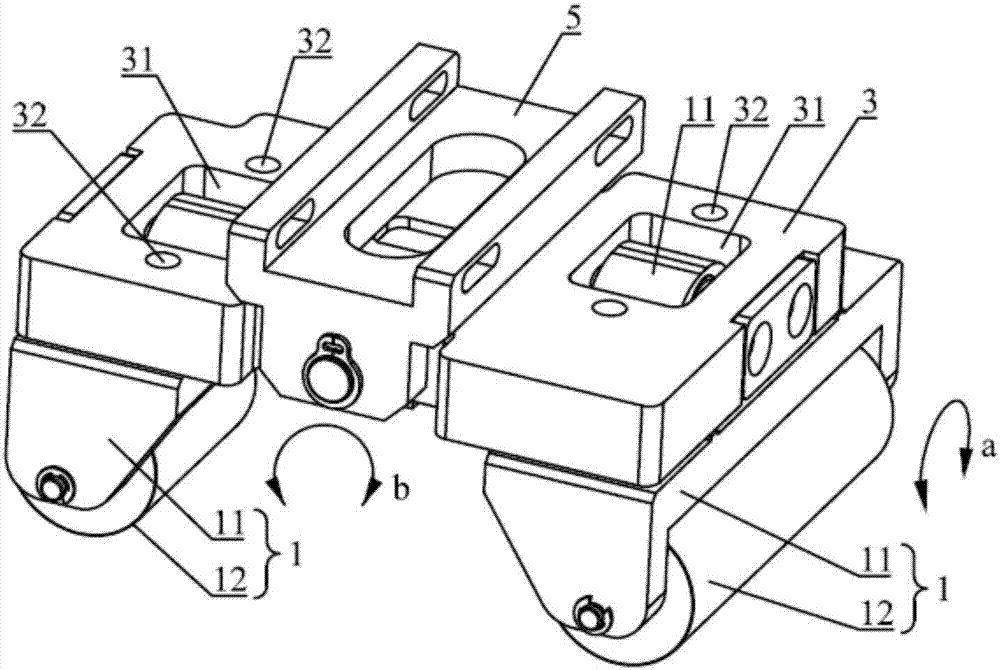

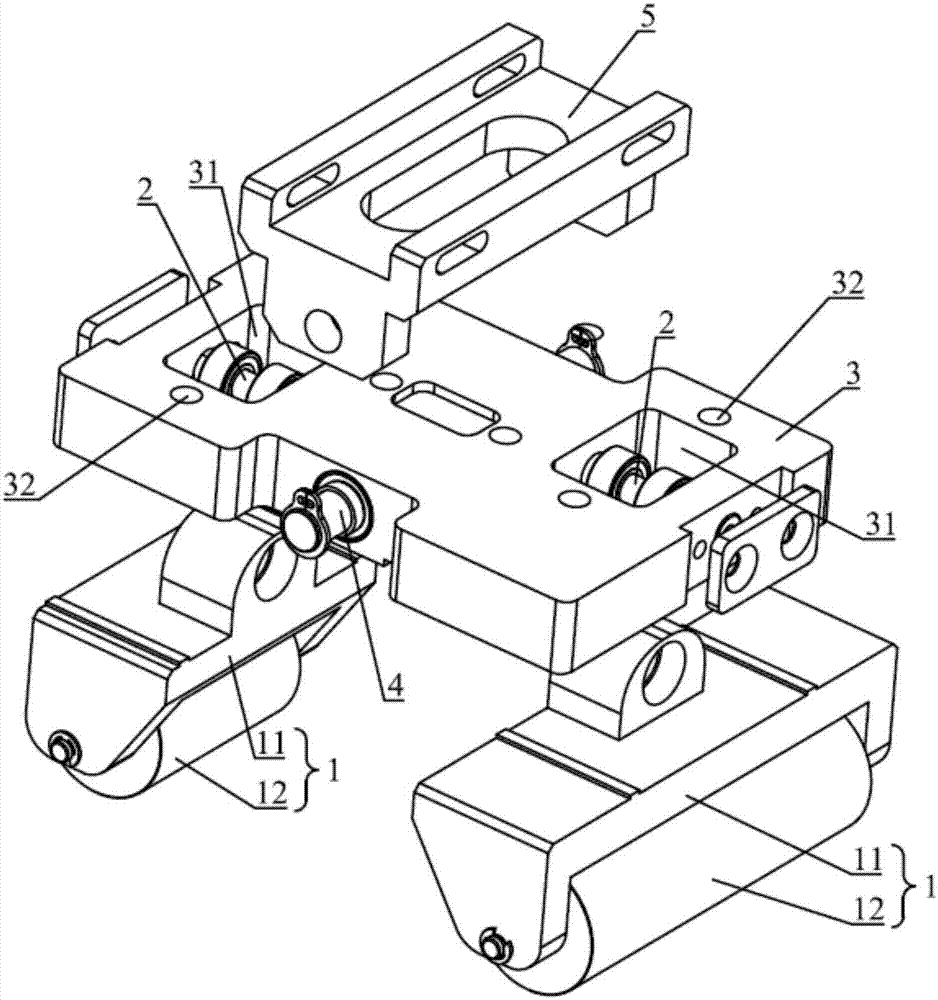

[0029] This embodiment provides a rolling mechanism, including a roller assembly 1 and an adjustment mechanism, the roller assembly 1 includes a roller 12 and a bracket 11, the roller 12 is rotatably connected to the bracket 11; the adjustment mechanism includes a fixed frame 3 and can be rotatably mounted on the fixed frame 3 of the first rotating shaft 2, the first rotating shaft 2 is rotationally connected with the fixed frame 3, and the bracket 11 is sheathed outside the first rotating shaft 2 and is rotationally connected with the first rotating shaft 2.

[0030] Specifically, the fixed frame 3 in this embodiment is used to fix one or more roller assemblies 1, and the fixed frame 3 is connected with other parts of the equipment through the connector 5; the fixed frame 3 is provided with an accommodating groove 31, the first The rotating shaft 2 can be accommodated in the accommodating groove 31, and the fixed frame 3 can rotate around the first rotating shaft 2; the roller...

Embodiment 2

[0035] This embodiment provides a laminating equipment, including the rolling mechanism in Embodiment 1, the fixed frame 3 and the roller 12 rotate around the first rotating shaft 2, so that the axis of the roller 12 can always be parallel to the surface to be rolled of the product , to adapt to the inclination of the surface of the product, so that the roller 12 provides uniform pressure on the surface to be rolled of the product, improves the rolling effect, and has good versatility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com