Metal product fast transferring and conveying equipment

A technology for transferring and conveying metal products, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems that the height and direction of material transmission cannot be adjusted arbitrarily, and the material transmission is not flexible enough, so as to achieve convenient transmission, stable transmission, and center of gravity smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

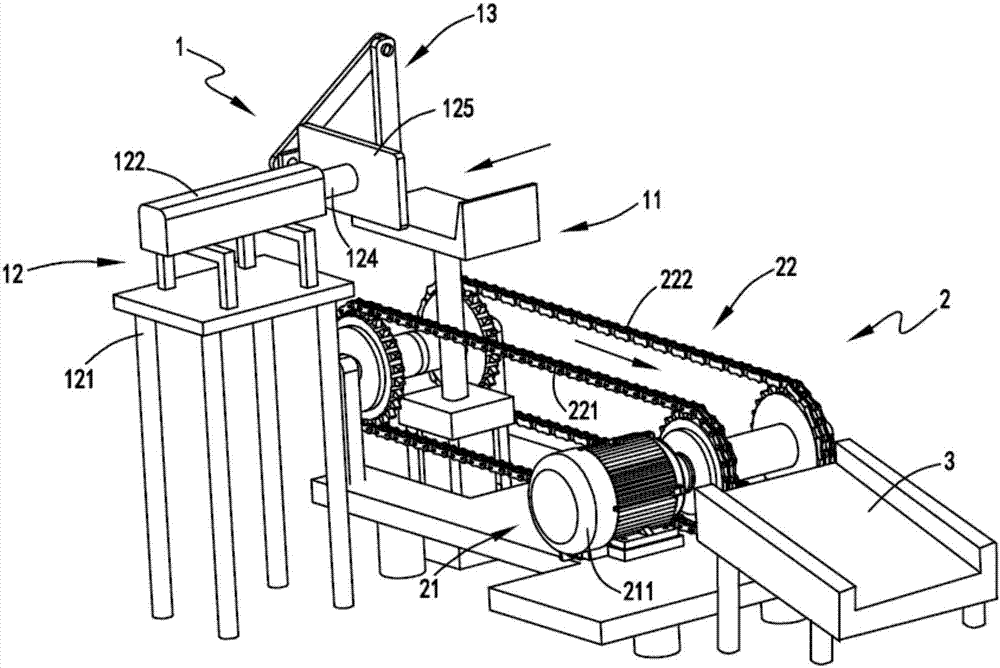

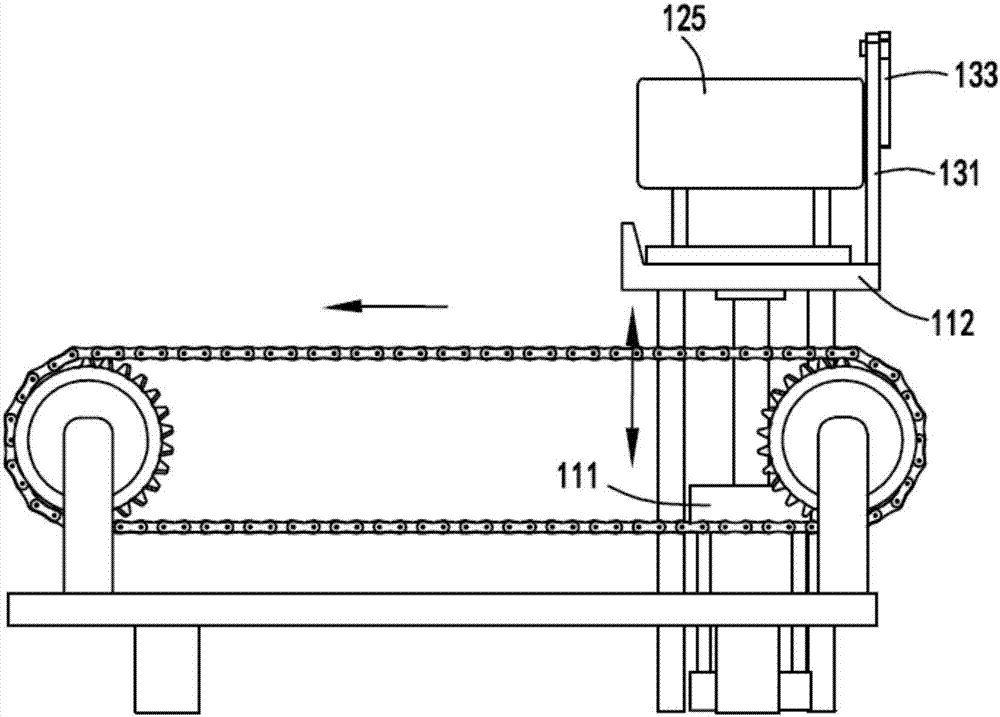

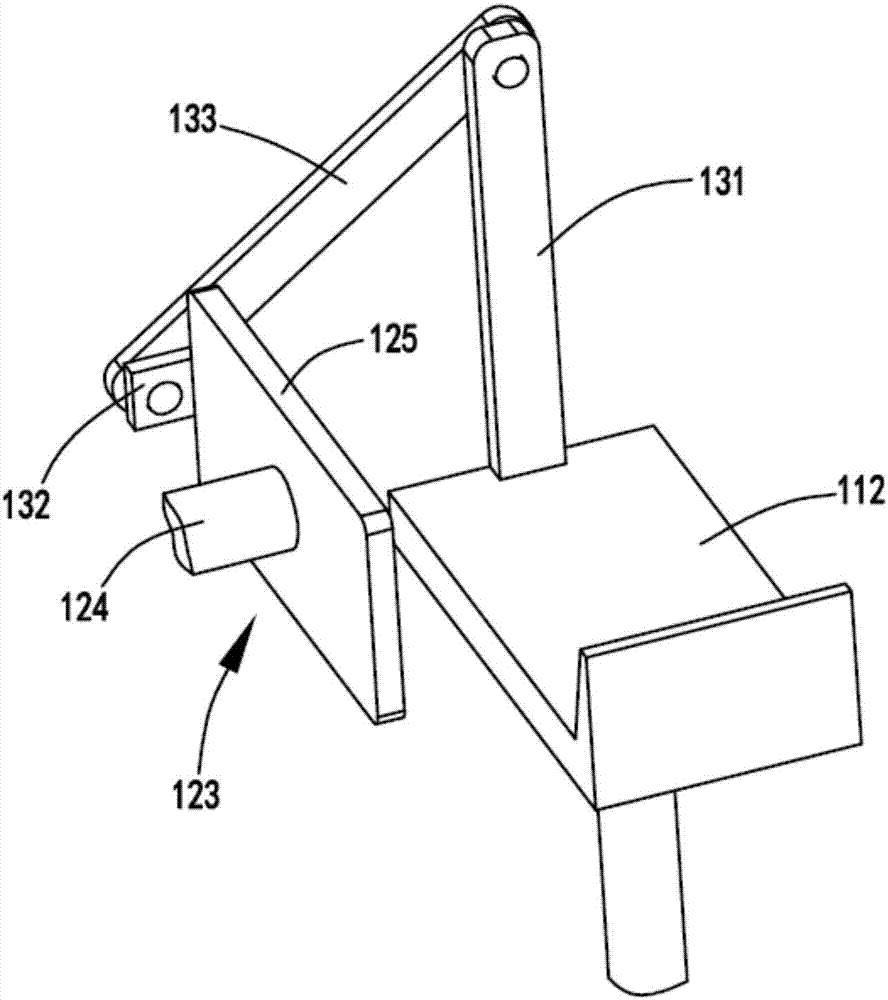

[0022] figure 1 It is a schematic diagram of the structure of the metal product rapid transfer conveying equipment, figure 2 It is a schematic diagram of the front view of the rapid transfer and conveying equipment for metal products, image 3 is a schematic diagram of the supporting mechanism, Figure 4 It is a schematic diagram of the structure when the material is transferred to the conveying device. Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a metal product rapid transfer conveying equipment includes a support mechanism 1, and the support mechanism 1 includes a load-bearing lifting device 11 for receiving the conveyed material and driving the material to move downward, and is arranged on one side of the load-bearing lifting device 11. The positioning device 12 for positioning the material on the load-bearing lifting device 11; the output mechanism 2, the output mechanism 2 includes a power device 21 and is used to accept the material on the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com