Knotting mechanisms and creels

A creel and path technology, applied in transportation and packaging, textiles and papermaking, thin material processing, etc., can solve the problems of hard work and labor, and achieve the effect of effortless physical strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

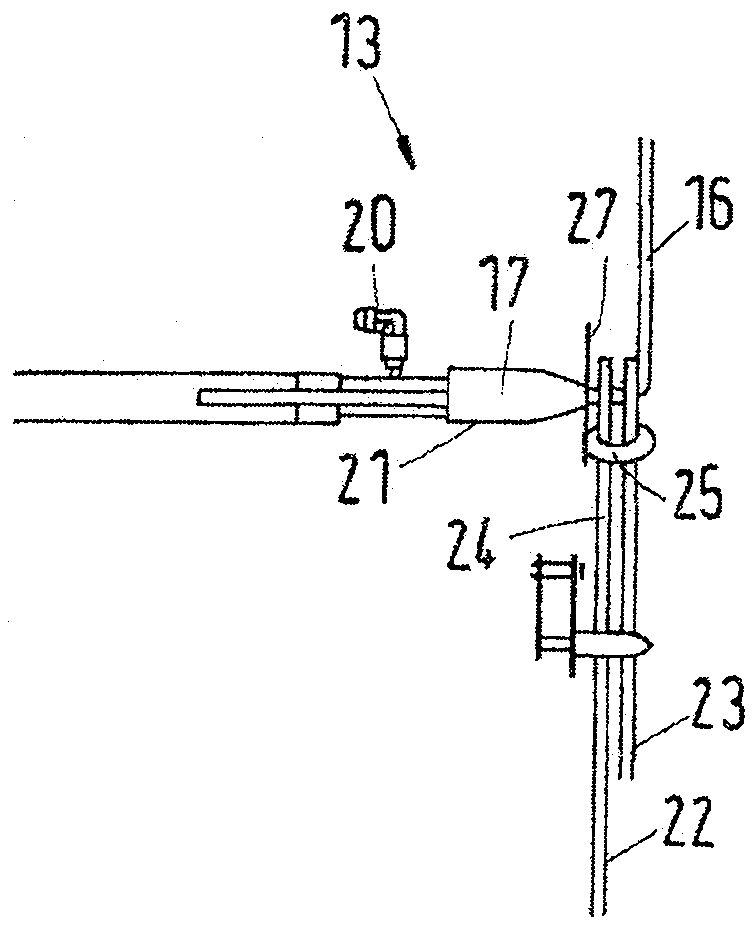

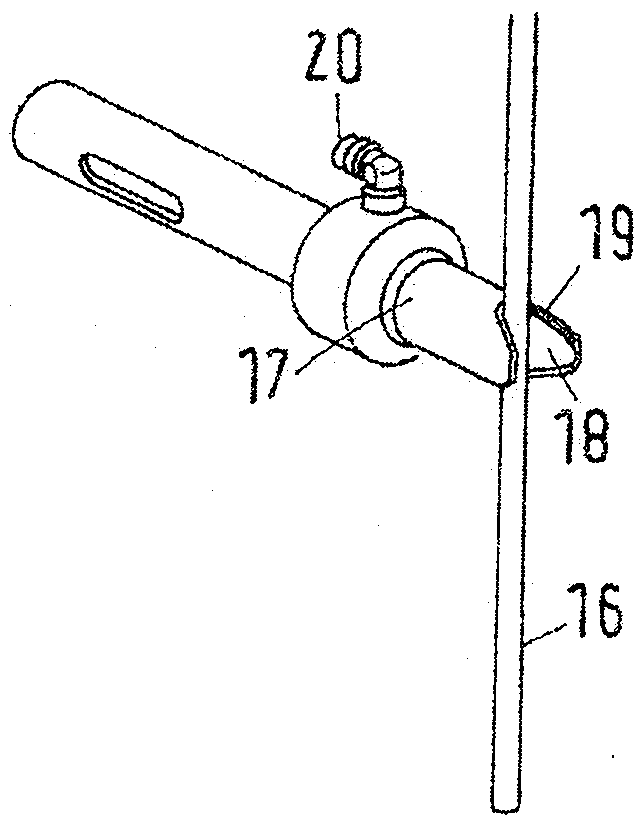

[0033] Referring first to a very schematic illustration of a creel 1 as described in Figure 9 as shown in.

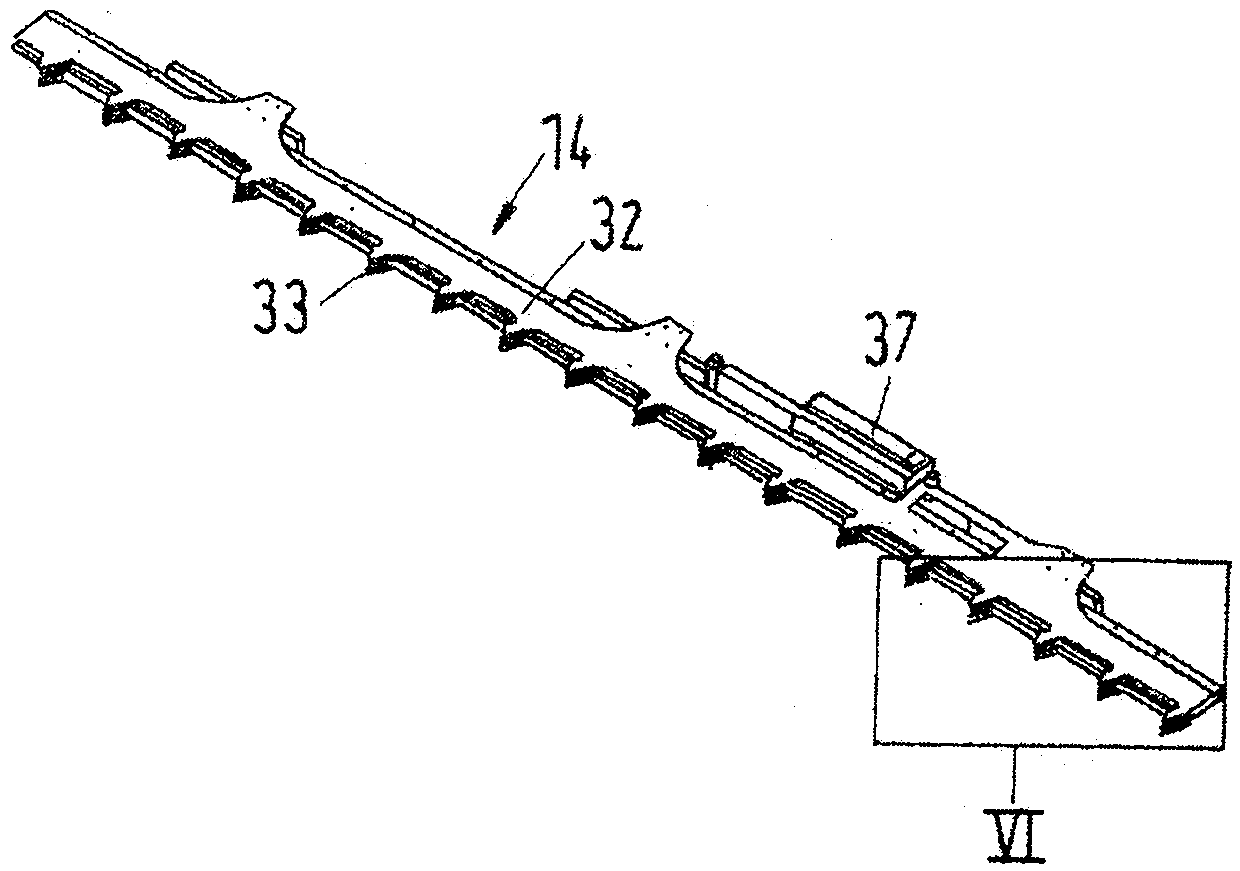

[0034] The creel 1 has two beam supports 2 , 3 , wherein a section warp beam 4 , 5 is arranged in each beam support 2 , 3 . Partial yarn sheets (teilfadenschar) 6 , 7 are withdrawn from each partial warp beam 4 , 5 . The slivered yarn sheets 6 , 7 are guided by deflection rollers 8 , 9 and joined after the last deflection roller 9 to form a yarn sheet 10 . The yarn sheet 10 is then delivered to the doubling device (or other processing mechanism) along the direction of arrow 11 . A device for feeding slurry can also be connected upstream of the paralleling device.

[0035] Of course, more than the two illustrated warp beam supports 2 , 3 can also be provided, so that more than two section warp beams 4 , 5 can also be accommodated in the creel 1 .

[0036] When the section warp beams 4, 5 need to be replaced (because, for example, the section warp beams 4, 5 are work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com