Load balancing control device and method for outriggers of bridge erecting machine

A technology of equalizing device and bridge erecting machine, which is applied in the direction of erecting/assembling bridges, bridges, and bridge construction, etc., can solve the problems of inability to anchor, move laterally, and cannot be inserted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

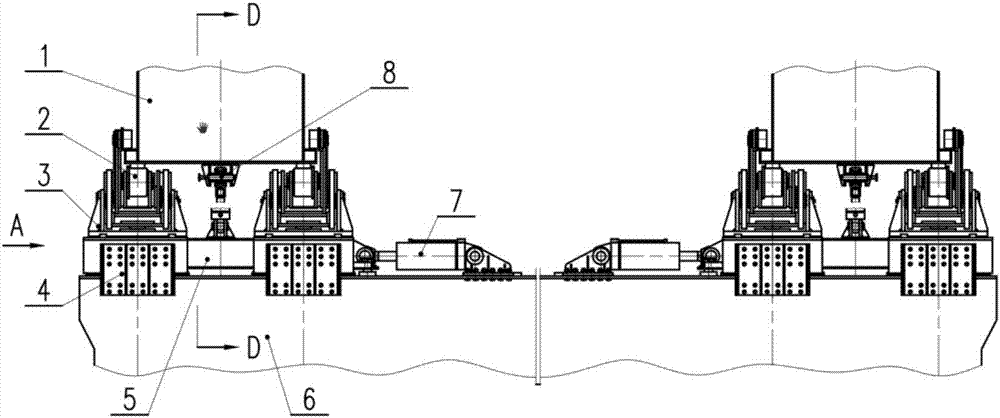

[0041] see figure 1 According to the present invention, the outrigger of the bridge-erecting machine is balanced under load and the main girder and outrigger anchoring device include a supporting wheel assembly (2), a hinge support (3), a buckle assembly (4), a traverse device (5), Traversing oil cylinder (7), anchoring device (8) and so on.

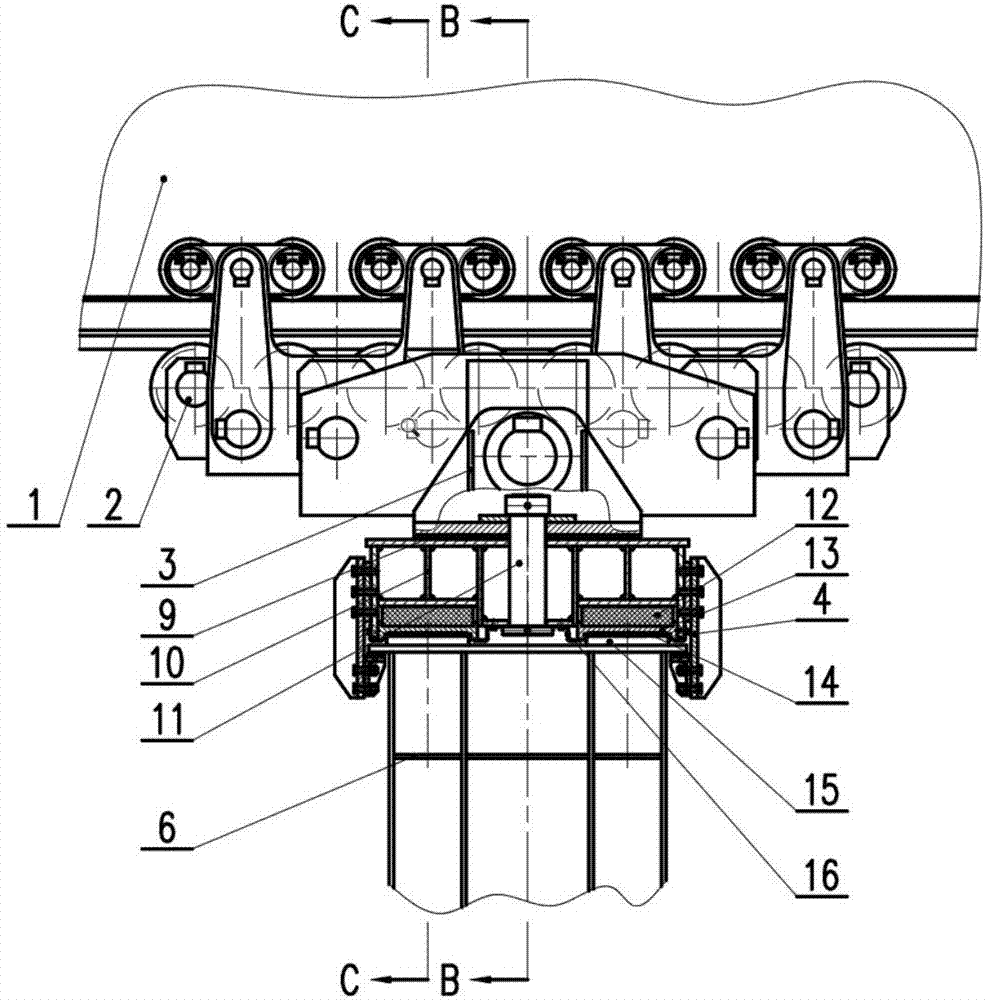

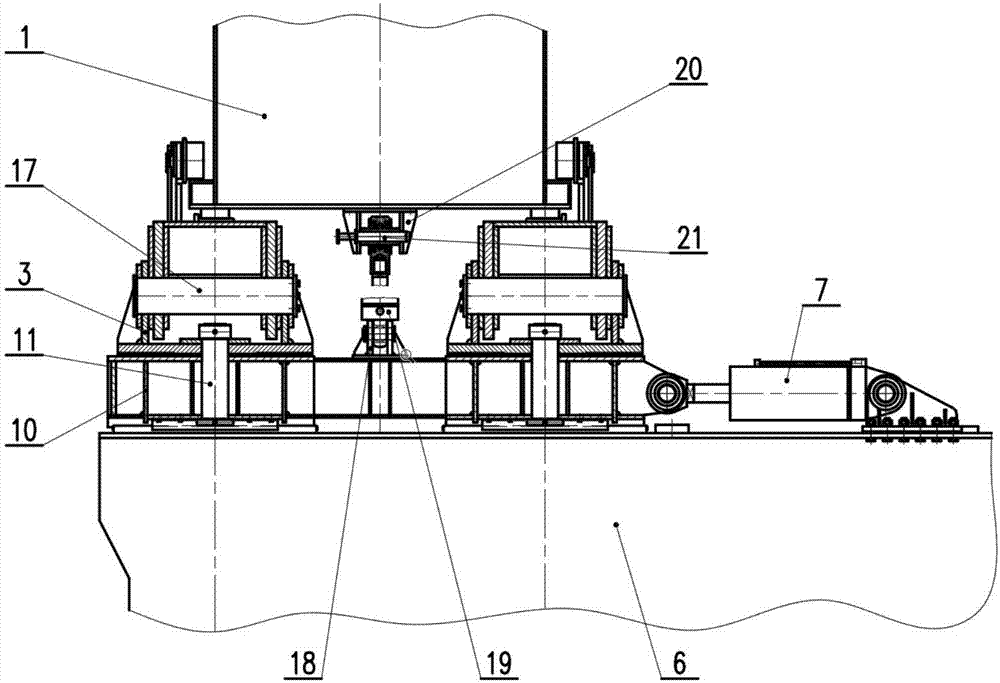

[0042] see figure 2 , image 3 with Figure 4 , the traversing device (5) is mainly composed of a traversing platform (10), a hinge support central axis (11), a left rubber support (12), a right rubber support (22), a card groove plate (13), a traversing It is composed of wear-reducing plate (14), traverse support (15), and sealing plate (16).

[0043] In order to ensure relative movement between the outrigger of the bridge erecting machine and the main girder (1), the outrigger adopts the supporting wheel assembly (2) to support the main girder (1) and is connected by rolling, that is, the main girder (1) It is pressed on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com