Self-pressure-relief quick coupling and working method thereof

A self-relieving and fast technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of cold plate scrapping, cold plate surface deformation, bulging, etc., achieve the effect of stable guidance and fast circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

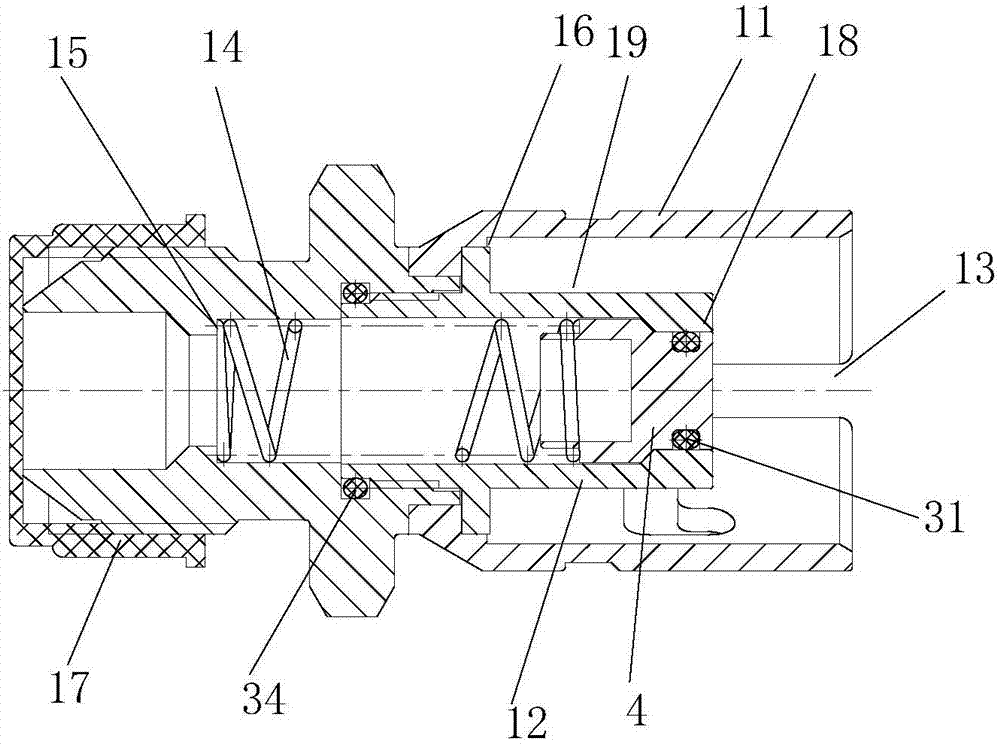

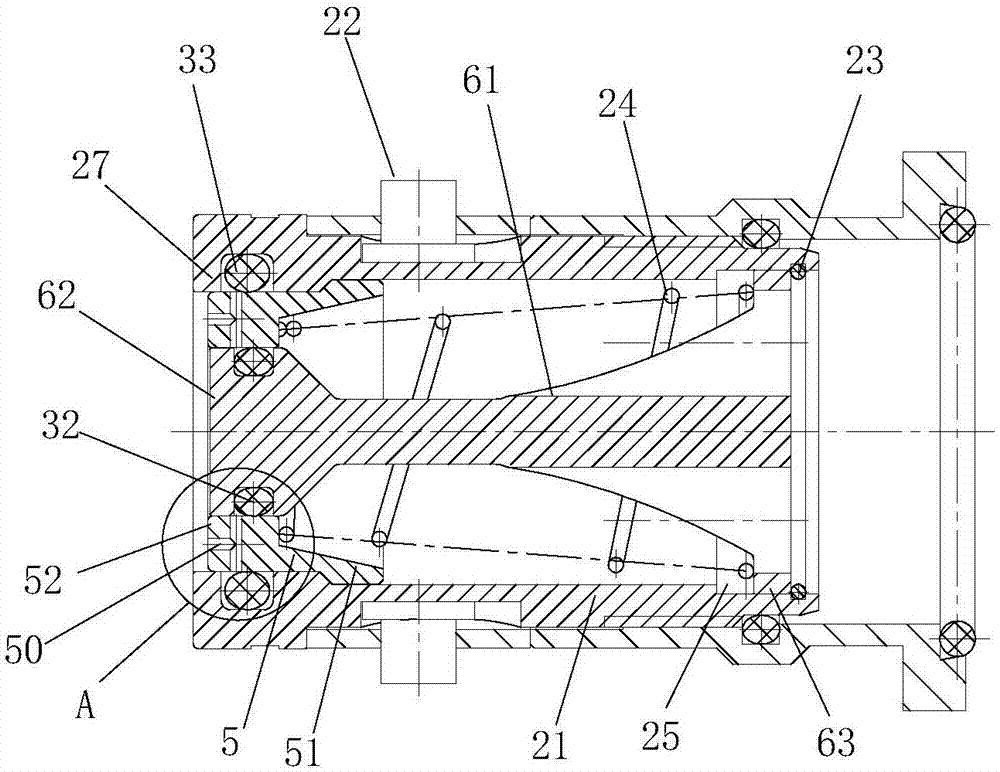

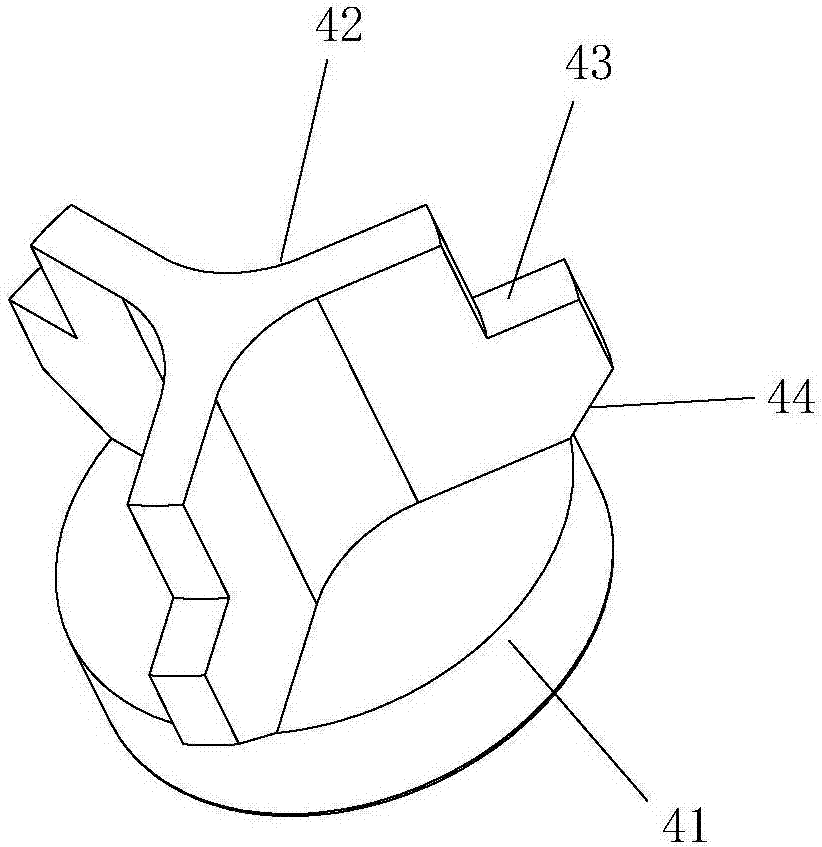

[0029] Embodiment 1 The self-relieving quick connector of this embodiment includes a male plug and a female plug that are plugged together (for the convenience of discussion, when the components in the male plug refer to the front end, it refers to the end close to the connection between the male plug and the female plug. The opposite end is the tail end; when the parts in the female plug refer to the tail end, it refers to the end near the connection between the male plug and the female plug, and the opposite end is the front end); figure 1 As shown, the male plug includes a first sleeve 11 of the male plug and a second sleeve 12 of the male plug. An annular connection portion 16 is arranged inside the first sleeve 11 of the male plug, and the tail end of the second sleeve 12 of the male plug is connected to the annular connection portion Threaded connection, so that a cylindrical cavity 19 is formed between the first sleeve 11 of the male plug and the second sleeve 12 of the ...

Embodiment 2

[0039] The working method of the self-relieving pressure quick connector as described in embodiment 1, comprises the steps:

[0040] A. When not mated, the male plug is in a closed state, the first spring 14 supports the first valve core 4 to reach the front end of the second sleeve 12 of the male plug, and the annular side wall of the first sealing disc 41 and the second sleeve of the male plug The first annular sealing portion 18 of the cylinder 12 is sealed and fitted through the first O-ring 31; the female plug is in a closed state, and the second spring 24 supports the second valve core 5 to reach the tail end of the first sleeve 21 of the female plug, and at the same time The annular bracket 23 supporting the valve stem 61 moves to the side wall of the annular groove 25 close to the front end of the first sleeve 21 of the female plug, and is limited by the first retaining ring 23, and the outer wall of the second valve core 5 passes through the third O-shaped The sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com