High-pressure-resistant energy-concentrated directional explosive charge, and use method thereof

A high-pressure-resistant, energy-gathering technology, applied in the field of anti-seepage walls, can solve problems such as inability to detonate explosives and inability to achieve effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

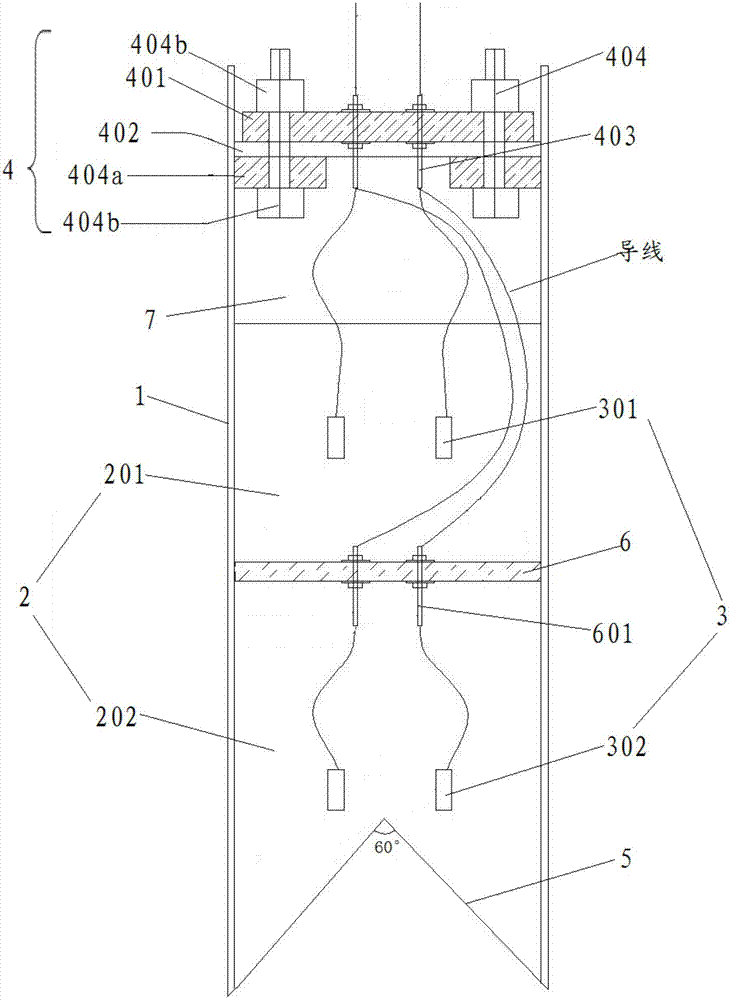

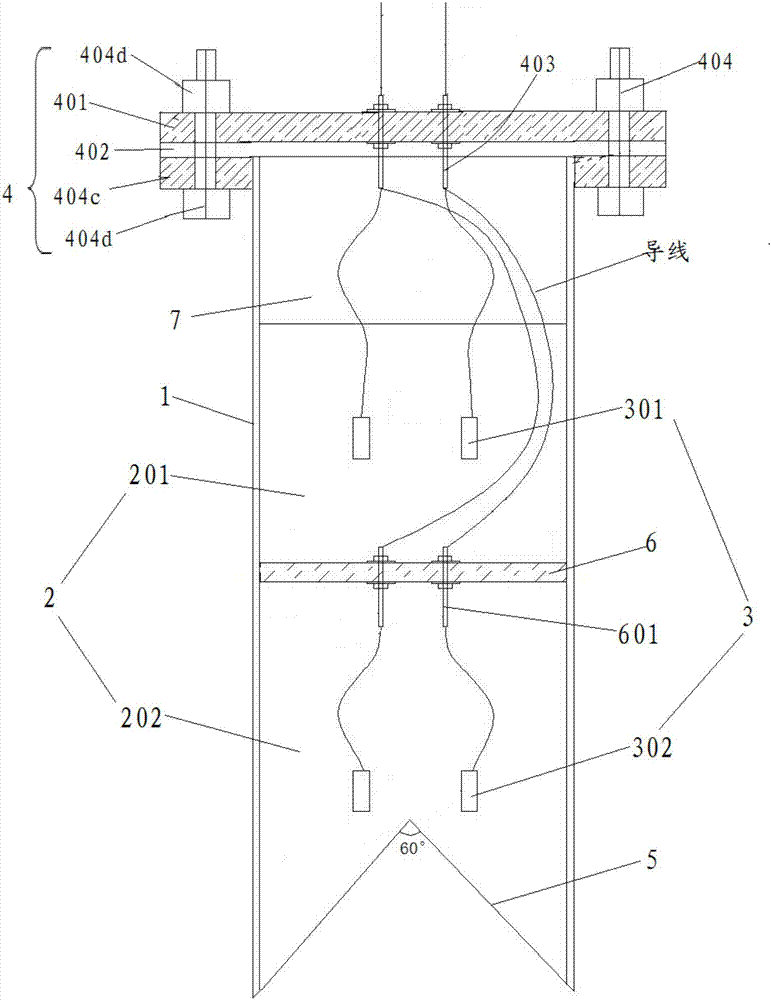

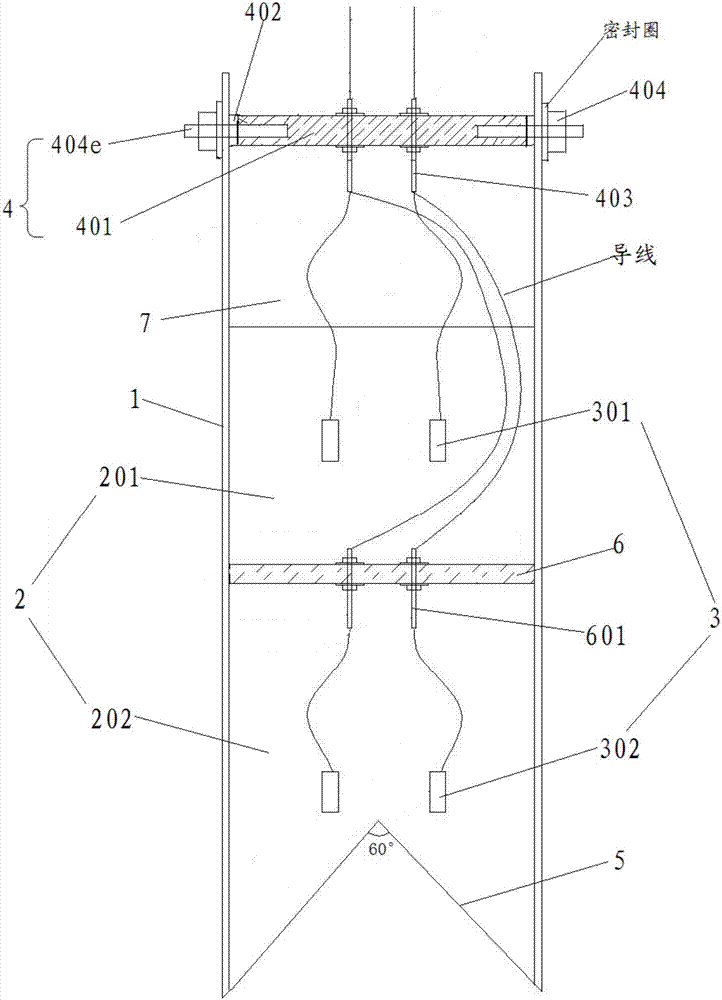

[0045] On the one hand, an embodiment of the present invention provides a high-pressure-resistant energy-forming directional bomb, which includes an explosive 2 and an electric detonator 3 located in a blasting cylinder 1, and the directional bomb further includes: waterproof sealing of both ends of the blasting cylinder 1 respectively. The first seal 4 and the second seal 5;

[0046] The first sealing member 4 includes a cover plate 401 that matches the diameter of the blasting cylinder 1, a sealing gasket 402 located at the connection between the cover plate 401 and the blasting cylinder 1, and passes through the cover plate 401 for connection. The wire of the electric detonator 3 and the first terminal 403 that transmits current, the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com