High-temperature and high-pressure liquid pressure and temperature measurement sensor based on ceramic package

A pressure sensor and temperature sensor technology, applied in measurement devices, instruments, etc., can solve problems such as affecting measurement accuracy, damaging measurement circuits, and sensitive components not being able to withstand high temperatures, so as to improve measurement accuracy, expand measurement functions, and increase high-pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

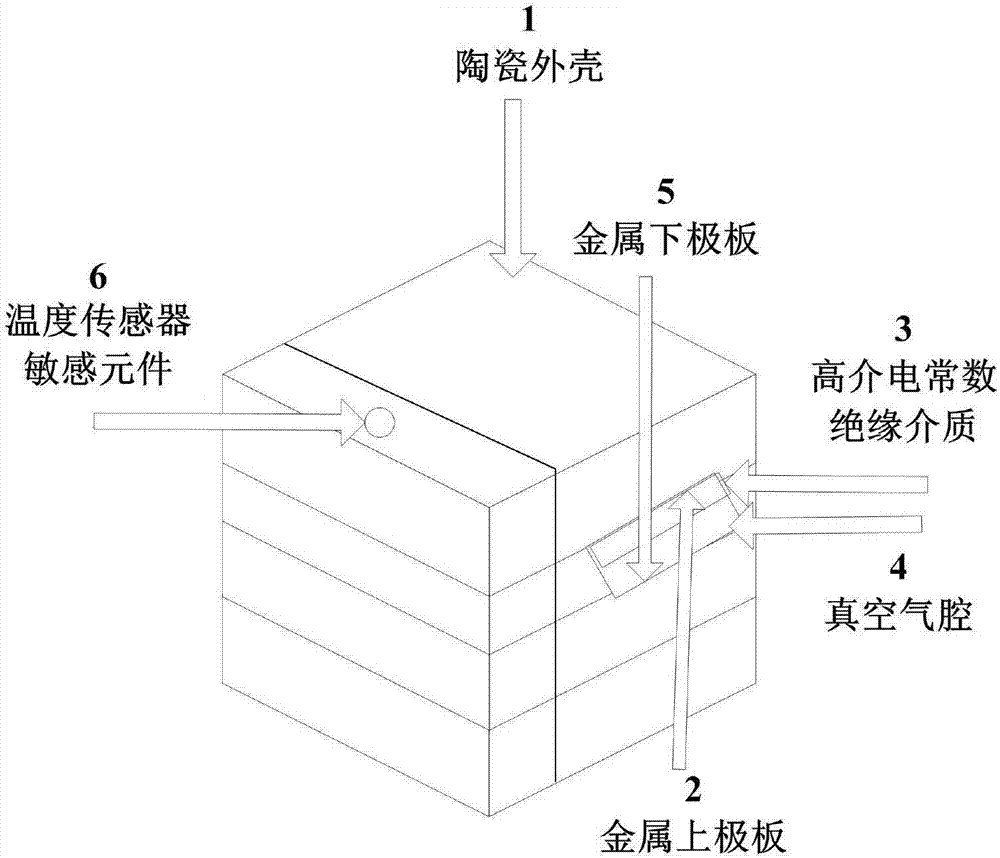

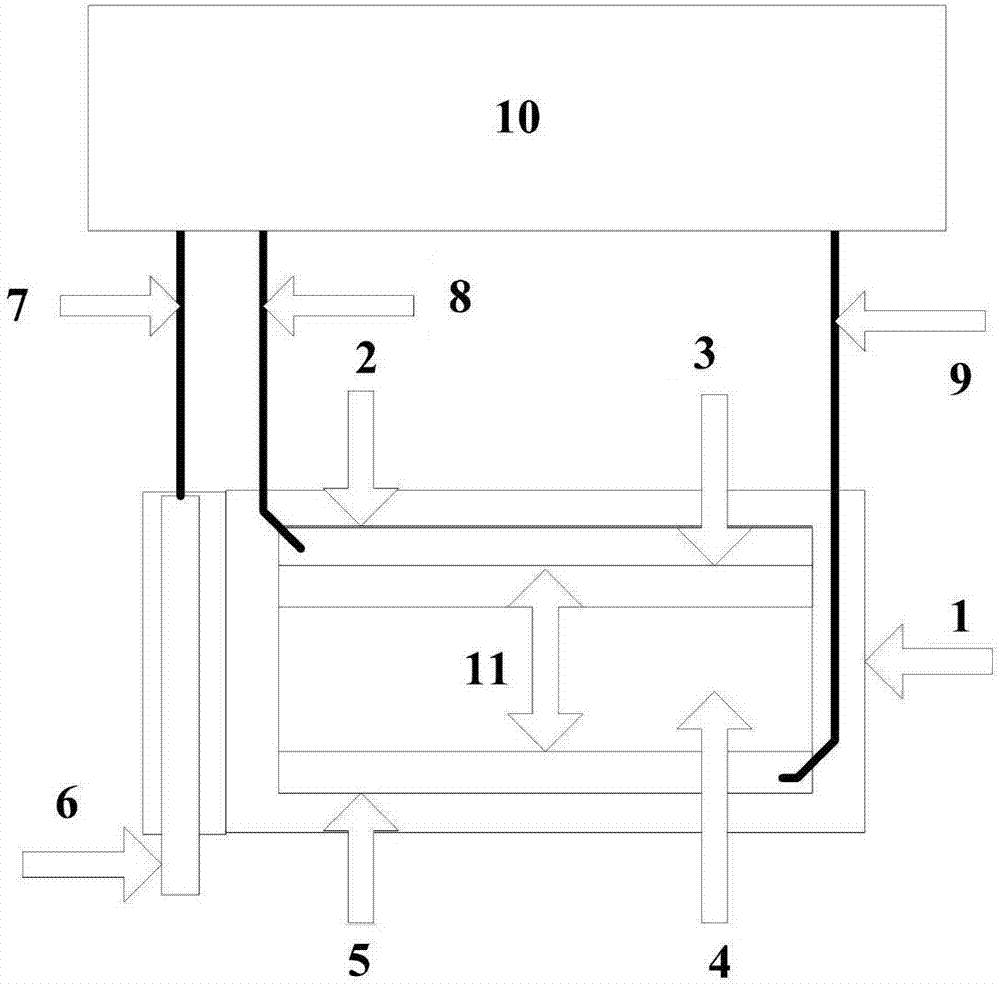

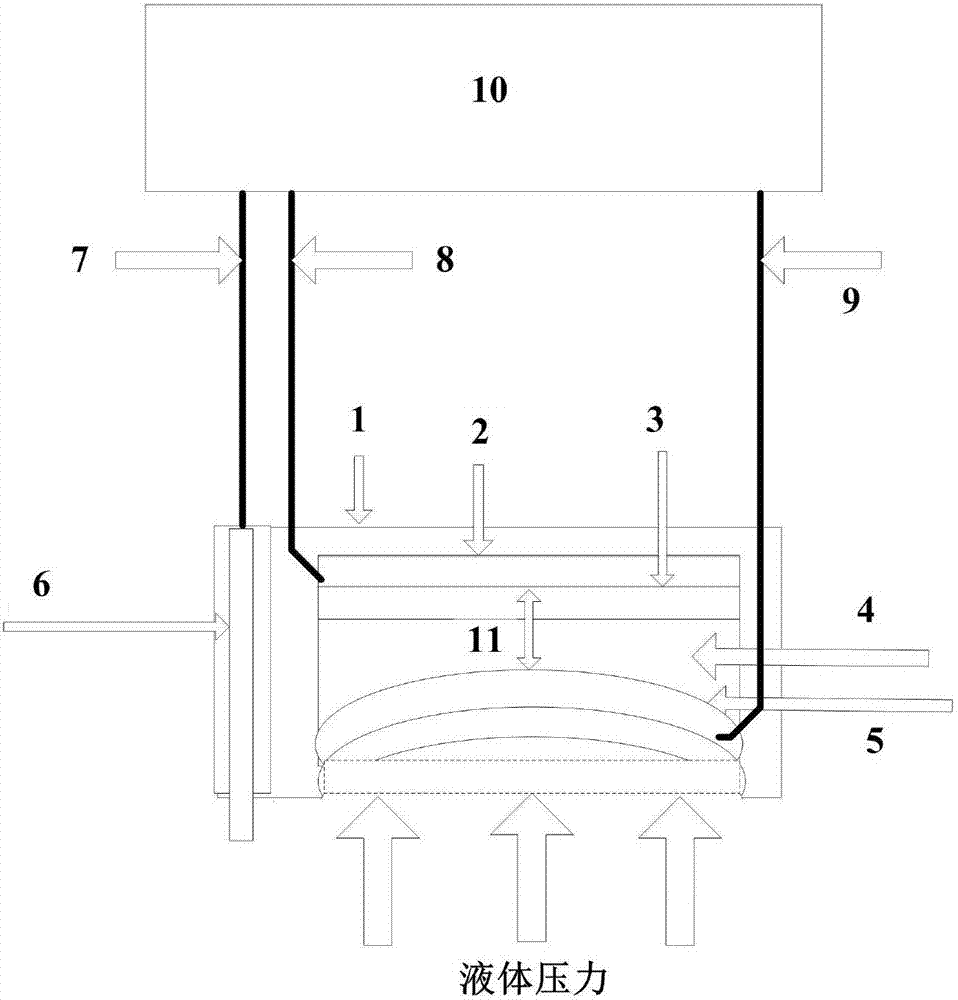

[0021] Such as figure 2 , image 3 As shown in , the sensitive element of the pressure sensor and the sensitive element of the temperature sensor wrapped by the ceramic shell are contacted with the measured liquid. During the measurement, the measured liquid impacts the lower part of the ceramic shell, bending the lower part of the ceramic shell, driving the metal lower plate to bend, and the metal upper plate Fixed, the distance between the two polar plates is relatively small, and the capacitance value of the sensitive element of the pressure sensor changes, resulting in a change in the resonant frequency of the resonant circuit connected to the measuring instrument. The internal resonant circuit of the measuring instrument is inductively coupled to a frequency sweeping circuit. The pressure data is measured according to the change of frequency. The temperature signal will also be obtained when the sensitive element of the temperature sensor touches the liquid to be measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com