Measurement device for measuring plate spring compressive force of fuel assembly

A technology for fuel assemblies and measuring devices, which is applied in measuring devices, force/torque/work measuring instruments, instruments, etc., and can solve problems such as inability to apply, complex structure of spring pressure testing machines, and inability to work underwater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

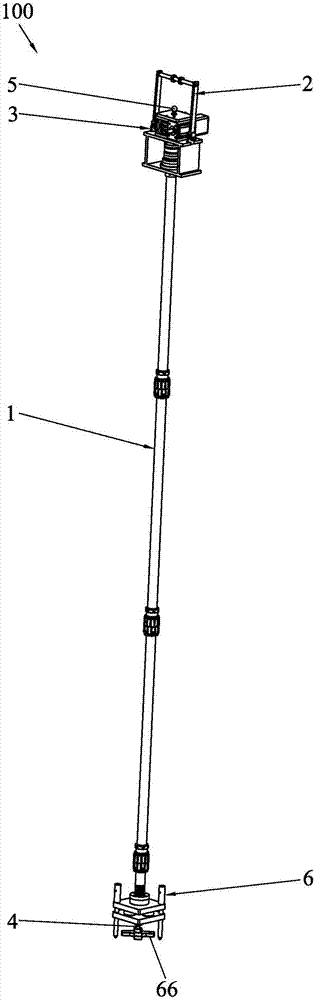

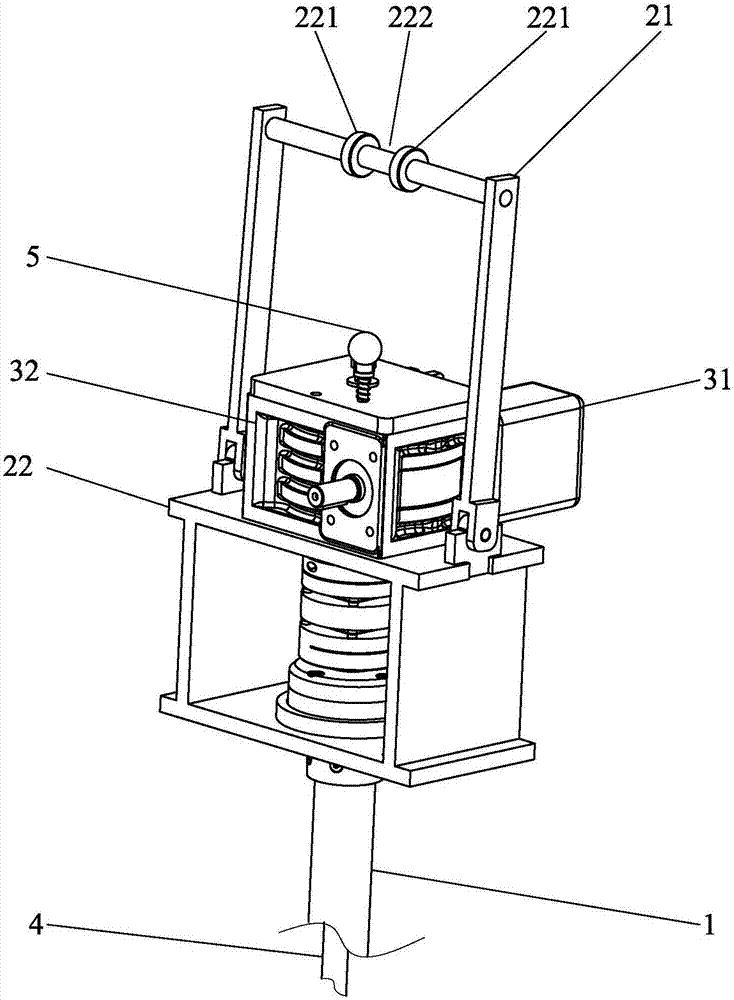

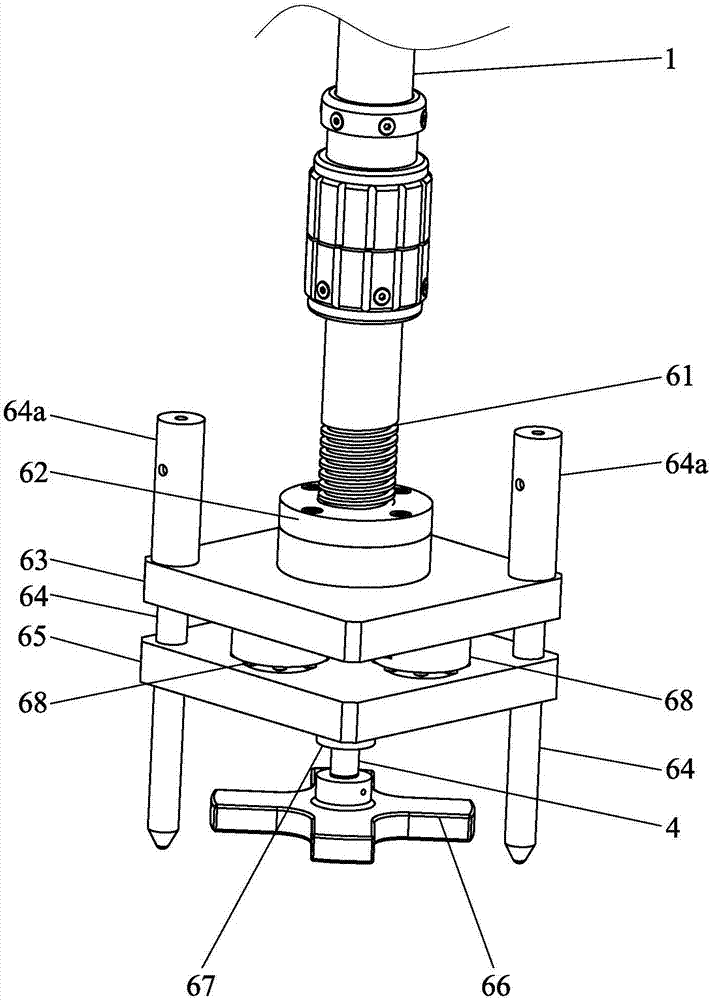

[0020] Such as Figure 1-Figure 4As shown, the fuel assembly leaf spring pressing force measuring device 100 of the present invention is used to measure the pressing force of the leaf spring in the upper tube seat of the fuel assembly. The fuel assembly leaf spring pressing force measuring device 100 includes an outer tube 1 , an upper supporting mechanism 2, a driving mechanism 3, a core rod 4, a handle 5 and a pressing force measuring mechanism 6, the outer tube 1 is a hollow structure, so that the outer tube of the present invention is a cylindrical structure; the upper supporting mechanism 2 includes Support base 21 and hanger 22, hanger 22 is arranged on the support base 21, and this hanger 22 is used for the hook of crane to hang, thereby the present invention is hoisted and moved; Driving mechanism 3 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com