Loading device and loading method for three-dimensional compound type crack growth test

A crack propagation and loading device technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of unseen three-dimensional crack testing loading devices, etc., to achieve convenient processing, accurate and reliable results strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

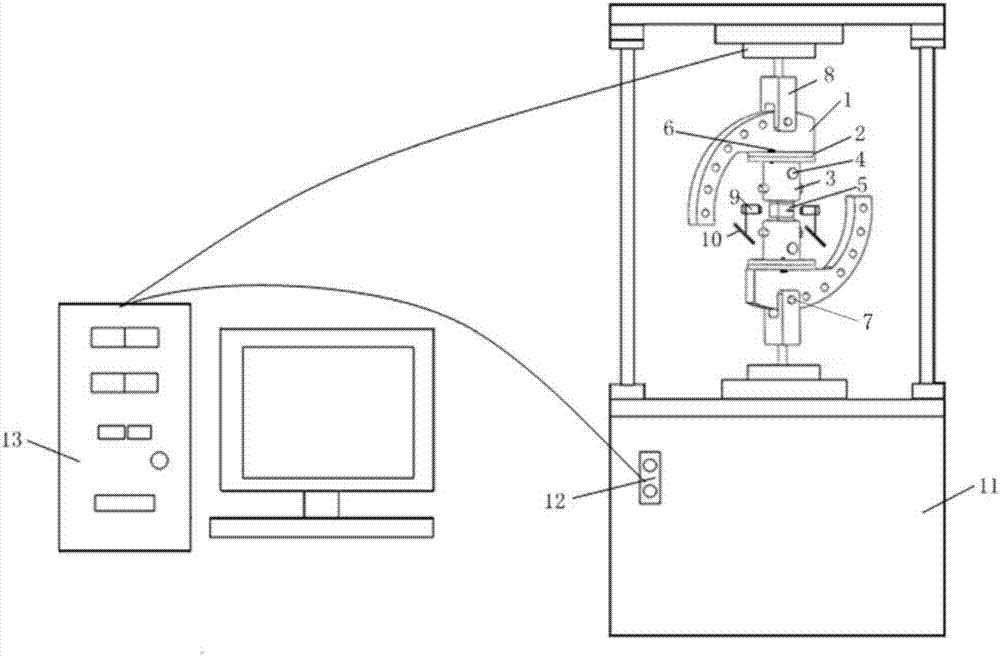

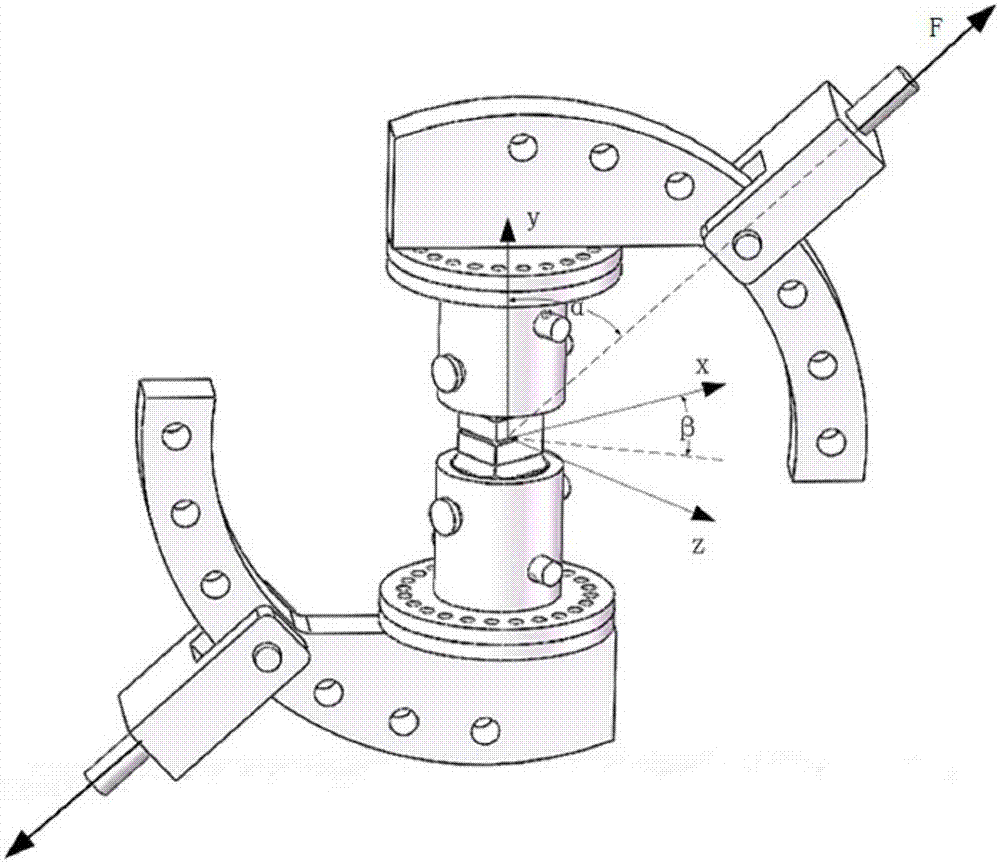

[0027] exist figure 1 Among them, the present invention is a loading device suitable for three-dimensional composite crack growth test, which is composed of internal fixture, external fixture, tested piece and testing system. The internal fixture includes: circular bushing 3 and pin shaft 4; the external fixture includes : C-shaped arc arm plate 1, circular plate 2, bolt 6, pin 7 and test machine chuck 8; the test system includes: high-power microscope 9, microscope reading rod 10, test machine 11, control switch 12 and test processing system 13.

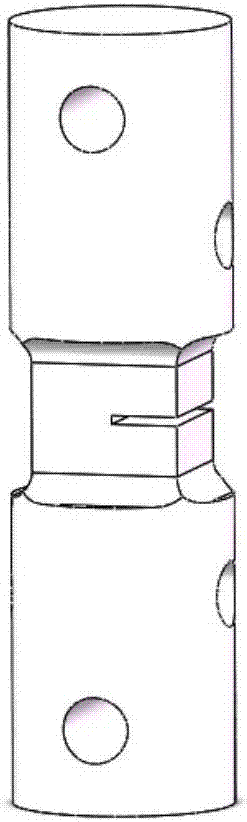

[0028] exist figure 2 , is a partial enlarged view of the tested piece 5, and the two ends of the tested piece 5 are cylindrical, which is for the convenience of connecting with the internal fixture. The central part of the test piece 5 is a cube, and the transition between the cylinder and the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com