Method for quantitatively identifying holes in leading wire melting trace

A technology for quantitative identification of internal holes, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of large differences in hole distribution, irregular appearance of wire melting marks, and inability to achieve quantitative identification, etc., to achieve convenient sampling operation and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with specific examples.

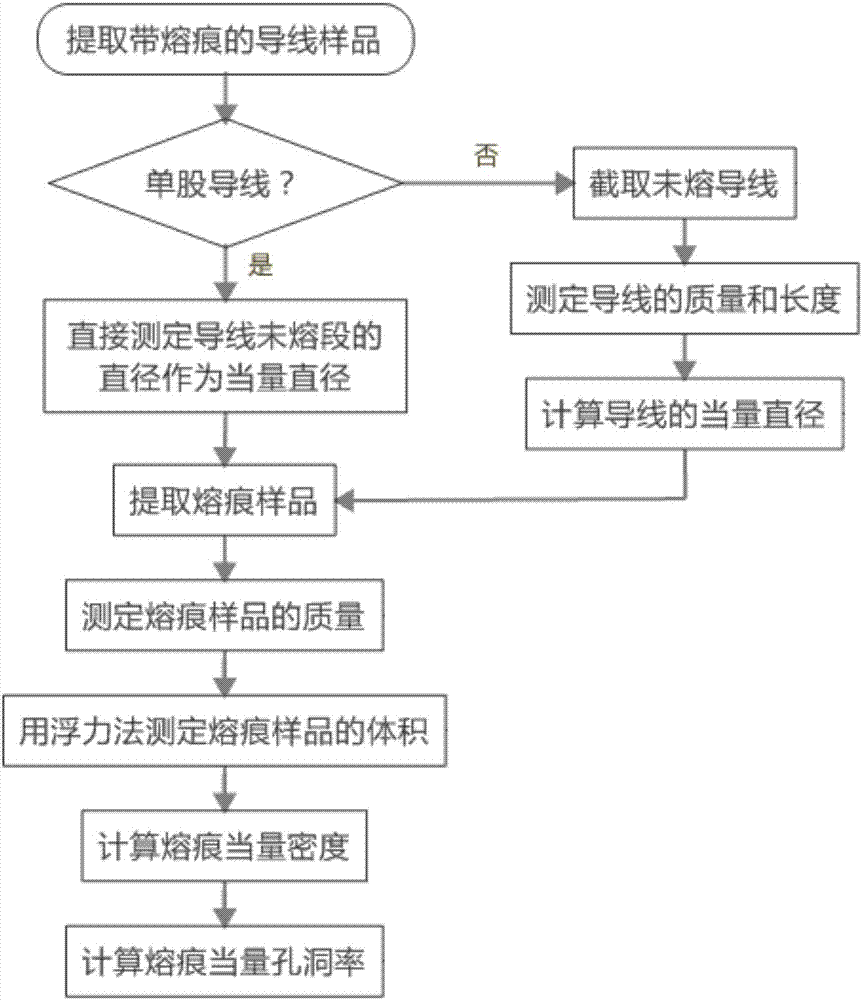

[0069] see figure 1 As shown, the quantitative identification method of the inner hole of the wire melting mark provided in this embodiment, the specific process is as follows:

[0070] 1) Extract the wire sample with melt marks.

[0071] 2) Determine whether the wire sample is a single-strand wire, and determine the equivalent diameter d of the unmelted section of the wire 0 ;

[0072] If the sample is a single-strand wire, directly use a vernier caliper to measure the wire diameter of the unmelted section as the equivalent diameter; if the sample is a multi-strand wire, cut off a section of unmelted wire, and use a vernier caliper to measure its length l 1 , and use an analytical balance to measure its mass m 1 , and then through the calculation formula Calculate the equivalent diameter of the multi-strand wire, where, ρ 1 is the density of the metal conductor materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com