Microscope hot stage

A microscope and heating stage technology, applied in the direction of electric heating device, ohmic resistance heating, discharge tube, etc., can solve the problems of narrow operating table, fragile material, damage, etc., and achieve the effect of easy portability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

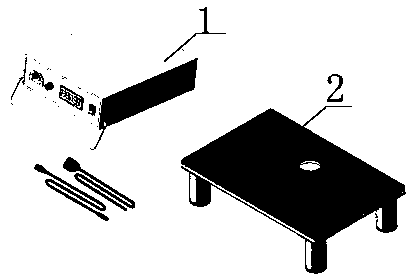

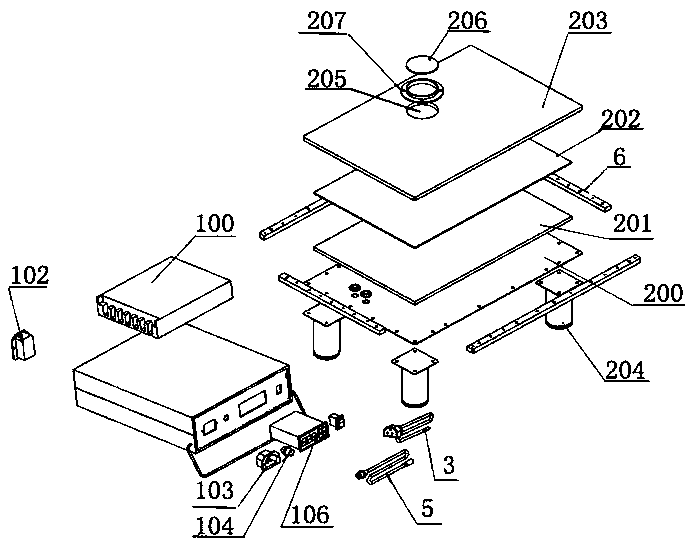

[0024] A heating stage for a microscope, including a temperature control cabinet 1, a heating stage 2 and connecting wires, its control flow diagram is as follows Figure 7 shown.

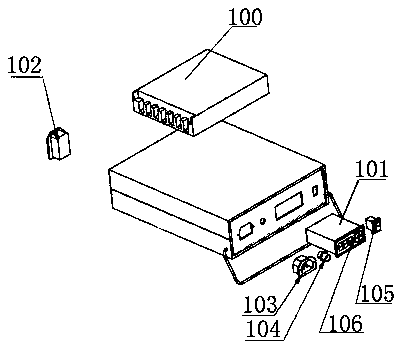

[0025] Such as figure 1 , figure 2 As shown, the temperature control cabinet 1 is provided with an AC / DC power supply 100 and a temperature controller 101, the rear end of the temperature control cabinet 1 is provided with a power socket 102, and the front end is provided with a heating socket 103, a temperature sensor socket 104 and switch 105 , the front end of the temperature controller 101 is a temperature control panel 106 protruding from the front surface of the temperature control cabinet 1 . Among them, the AC / DC power supply 100 can keep the 220V laboratory power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com