Flexible display panel and preparation method thereof

A flexible display and panel technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as screen scrap, film breakage, and wiring breakage thin-film transistor damage, to avoid wire breakage, The effect of good conductivity and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

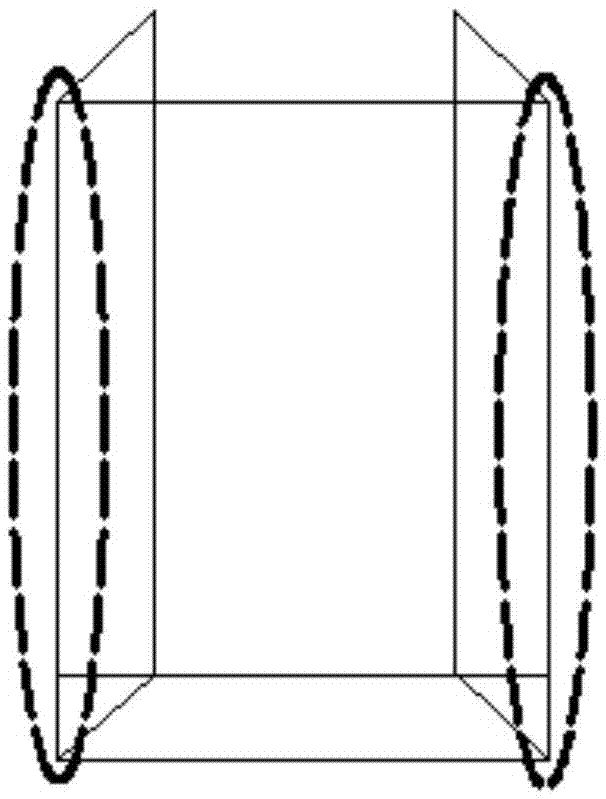

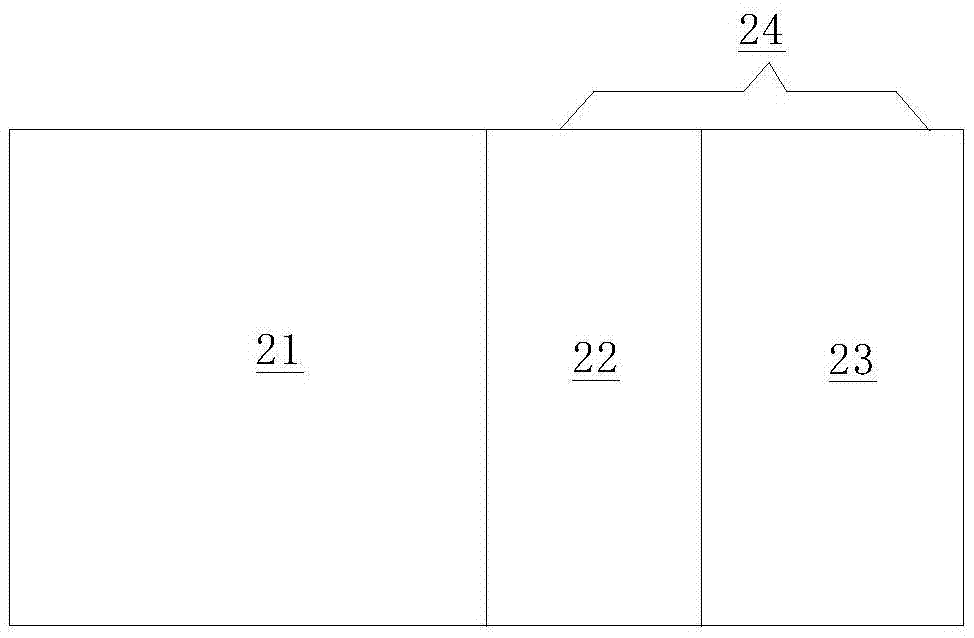

[0037] Such as figure 2 As shown, a flexible display panel provided by the present invention is provided with an adjacent display area 21 and a frame area 24, and the frame area 24 includes a non-folding area 23 and a folding area 22 between the non-folding area 23 and the display area 21 .

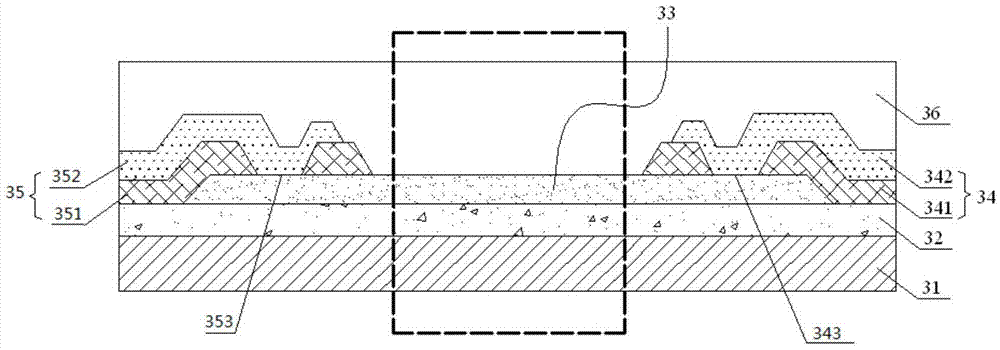

[0038] Specific to the layered structure, refer to image 3 , the flexible display panel of the present invention mainly includes:

[0039] The substrate 31, as a preferred embodiment, the material of the substrate 31 in this embodiment may be a PI substrate.

[0040] On the upper surface of the substrate 31, a layer of buffer layer (Buffer) 32 is covered; on the upper surface of the buffer layer 32, the corresponding figure 2 The position of the middle folding area 22 is covered with a graphene layer 33 , and the graphene layer 33 can be used to form circuit traces of the folding area 22 .

[0041] Further, on the upper surface of buffer layer 32 and the upper surface of part of gr...

Embodiment 2

[0047] This embodiment provides a method for preparing a flexible display panel. The flexible display panel is provided with an adjacent display area and a frame area, and the frame area includes a non-folding area and a folding area between the non-folding area and the display area. Such as Figure 2-4 Shown, the preparation method of the present embodiment mainly comprises:

[0048] First, a substrate 31 is provided, and the substrate is preferably a PI substrate.

[0049]Next, the buffer layer 32 is prepared on the upper surface of the substrate 31 by means of plasma enhanced chemical vapor deposition or the like.

[0050] Again, a graphene layer 33 is prepared on the upper surface of the buffer layer 32 corresponding to the folding region 22; the preparation method of the graphene layer 33 includes: chemical vapor deposition method, epitaxial growth method, micromechanical exfoliation method or graphite oxide reduction method, etc. Among them, the specific process of che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com