Printing process of a haircut scissors sign board

A technology of sign boards and hair clippers, which is applied in the field of hair clippers, can solve the problems of increasing waste rate, difficulty in infiltration, and affecting bonding strength, etc., and achieve the effects of improving work efficiency, preventing blurred printing, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The sign board is a plastic material with toughness, and the specific steps are as follows:

[0036] a. Injection molding: Select ABS plastic plate, and inject it into an arc-shaped sign plate on the injection molding machine. The length is 6.0cm, the width is 1.2cm, and the thickness is 0.1cm. The arc of the sign plate is less than or equal to the circle where the arc is located. semi-circular radian;

[0037] b. Surface treatment: Grind the outer surface of the sign board by sandblasting and emery cloth grinding. After grinding, put it in a degreasing solvent mixed with 20% acetone and 25% absolute ethanol for degreasing. After degreasing, put it in 55 % chromic acid solution, immersed at 50°C for 20 minutes;

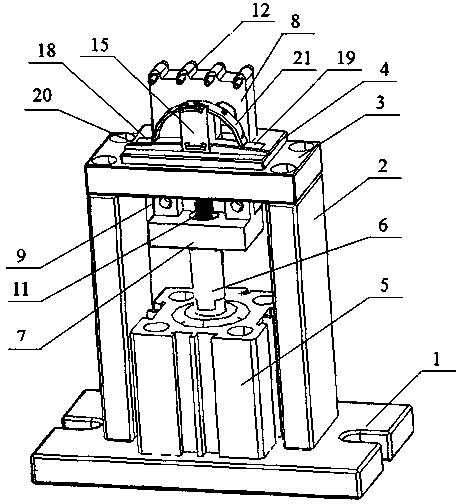

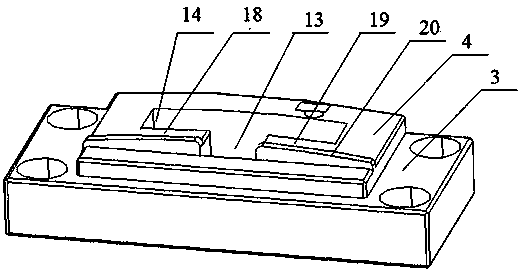

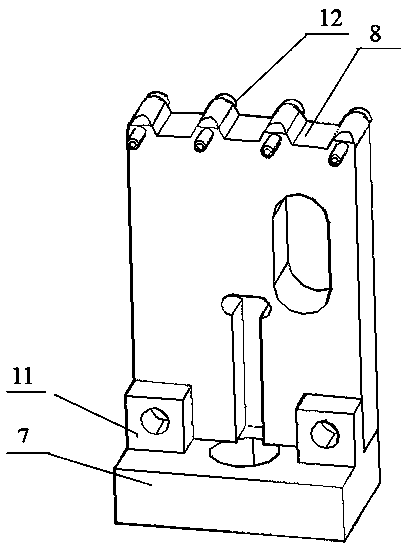

[0038] c. Positioning: Put the sign board into the special positioning tool, and the positioning tool presses the arc-shaped sign plate into a horizontal structure;

[0039] d. Printing: start the printing machine, the brush head part of the printing machine ...

Embodiment 2

[0042] The sign board is a plastic material with toughness, and the specific steps are as follows:

[0043] a. Injection molding: Select ABS plastic plate, and inject it into an arc-shaped sign plate on the injection molding machine, with a length of 8.0cm, a width of 1.5cm, and a thickness of 0.2cm. The arc of the sign plate is less than or equal to the circle where the arc is located. semi-circular radian;

[0044]b. Surface treatment: Grind the outer surface of the sign board by sandblasting and emery cloth grinding. After grinding, put it in a degreasing solvent mixed with 25% acetone and 30% absolute ethanol for degreasing. After degreasing, put it in 45 % chromic acid solution, placed at 55°C for 25 minutes;

[0045] c. Positioning: Put the sign board into the special positioning tool, and the positioning tool presses the arc-shaped sign plate into a horizontal structure;

[0046] d. Printing: start the printing machine, the brush head part of the printing machine is e...

Embodiment 3

[0049] The sign board is a plastic material with toughness, and the specific steps are as follows:

[0050] a. Injection molding: Select a plastic plate made of ABS material, and inject it into an arc-shaped sign plate on an injection molding machine. The length is 9.0cm, the width is 2.0cm, and the thickness is 0.3cm. The arc of the sign plate is less than or equal to the circle where the arc is located. semi-circular radian;

[0051] b. Surface treatment: Grind the outer surface of the sign board by sandblasting and emery cloth grinding. After grinding, put it in a degreasing solvent mixed with 30% acetone and 35% absolute ethanol for degreasing. After degreasing, put it in 35 % chromic acid solution, placed at 60°C for 30 minutes;

[0052] c. Positioning: Put the sign board into the special positioning tool, and the positioning tool presses the arc-shaped sign plate into a horizontal structure;

[0053] d. Printing: start the printing machine, the brush head part of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com