Soft base ground anchoring method

A surface anchoring and base technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as unstable fixation, affecting the implementation of vehicle resistance system, etc., to solve anchoring problems, enhance positioning force, friction force added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

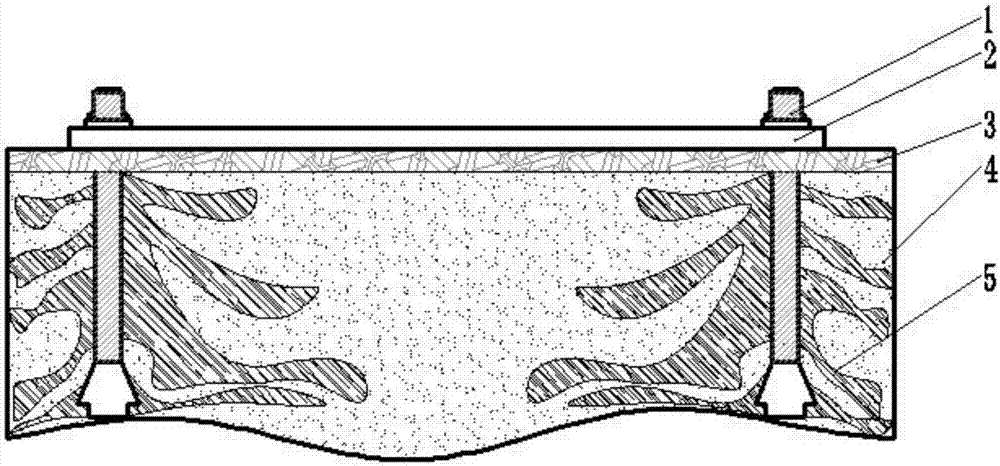

[0015] See attached figure 1 , the soft ground ground anchoring method of the present invention comprises the following steps:

[0016] Step 1: Drill installation holes through the soft ground punching device at the position corresponding to the position to be installed on the soft ground and the connection hole on the connection base 2;

[0017] Step 2: Pour the planting glue into each installation hole in step 1, make sure there are no air bubbles or gaps in the holes, and inject glue to 2 / 3 of the hole depth;

[0018] Step 3: Drive the two-way internal expansion bolt 1 through each connection hole on the connection base 2 into the hard thin layer 3 on the top of the soft base surface and the part filled with the planting glue formed in step 2. After hardening, place the The ground soft base layer 4 forms the hardened part 5 of the plant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com