Temporary reinforcing method of circular pipe components

A technology for round pipes and components, which is applied in the field of temporary reinforcement of round pipes, can solve the problems of increased workload, inconvenient reinforcement of temporary rods, increased structural steel consumption, etc., to achieve convenient construction, avoid structural review workload, The effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

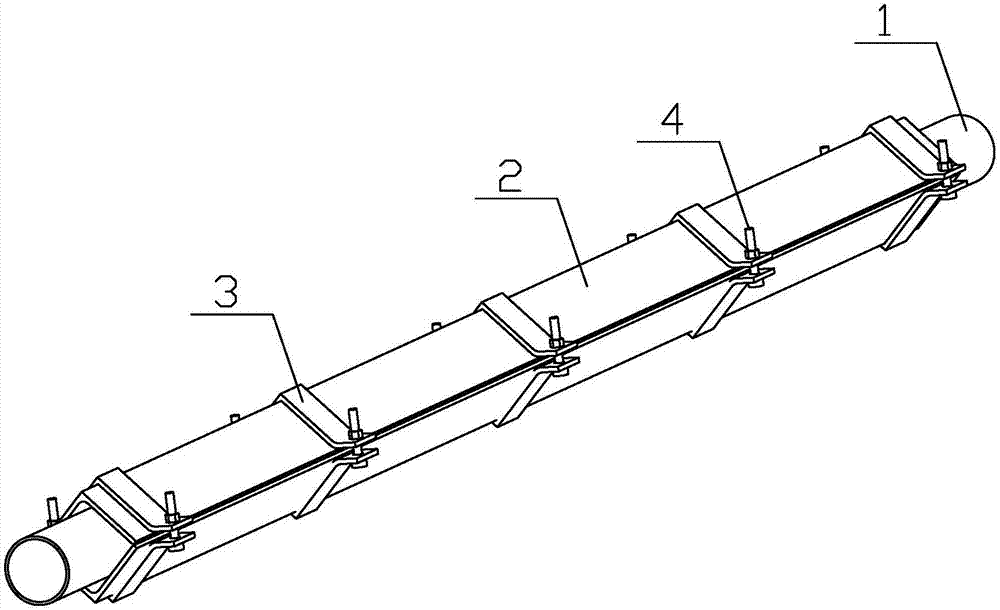

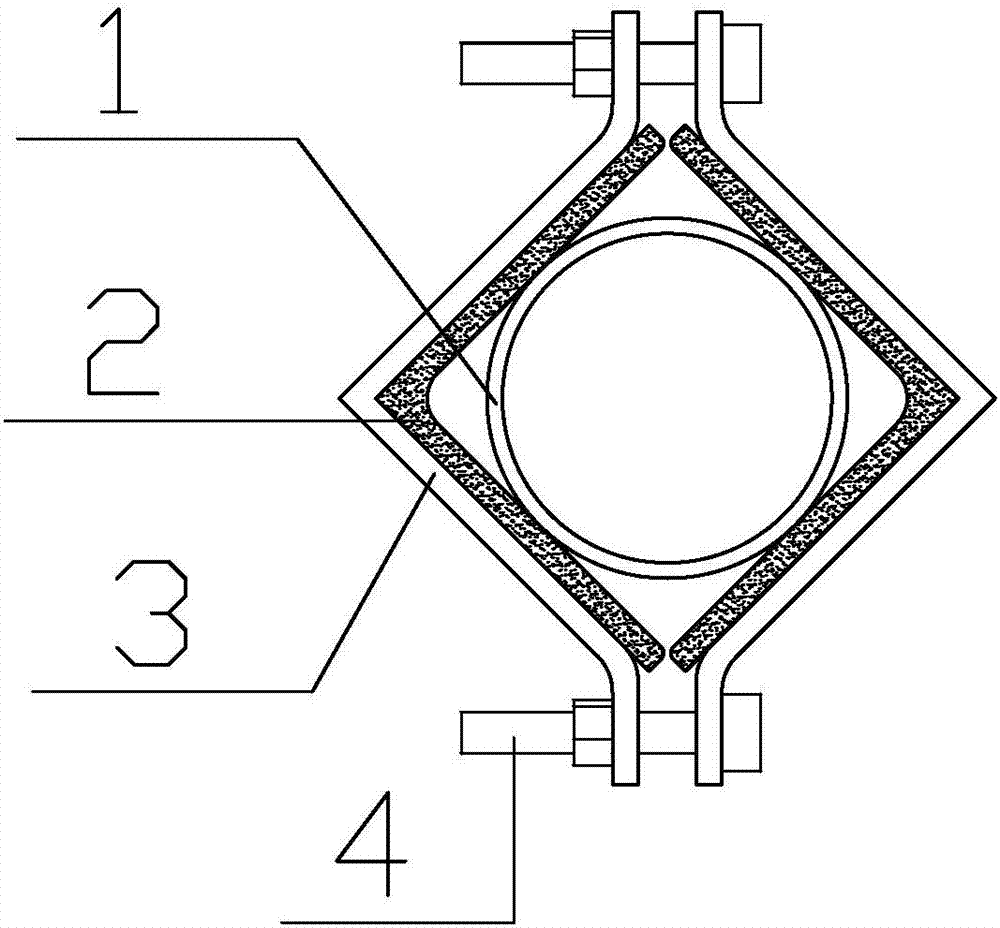

[0017] Such as Figure 1-3 As shown, what the present invention discloses is a kind of circular pipe member temporary reinforcement method, comprises the following steps:

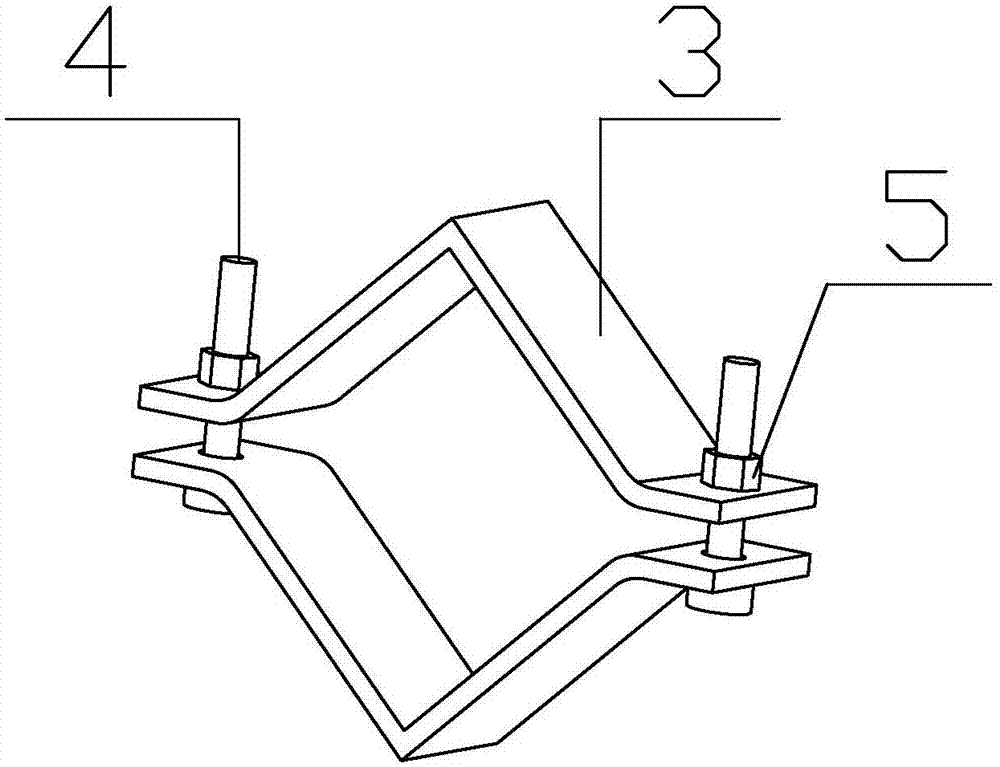

[0018] (1) According to the specifications of the reinforced round pipe 1, select or process it into matching angle steel 2 and angle steel fastener 3.

[0019] (2) According to the length of the reinforced round pipe 1, determine the length of the angle steel 2 and the number of angle steel fasteners 3;

[0020] (3) Before the reinforced round pipe 1 is stressed, two angle steels 2 are arranged symmetrically on both sides of the reinforced round pipe 1 and fixed by angle steel fasteners 3;

[0021] (4) After the structural construction is unloaded, loosen the angle steel fastener 3, remove the angle steel 2, and complete the reinforcement of the reinforced round pipe 2.

[0022] Further, the specification of the above-mentioned angle steel 2 is an equilateral angle steel, and the side length of the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com