Pipe type air guiding device with damping for air compressor rotor

A compressor rotor and damping tube technology, which is applied to the air inlet of the turbine/propulsion unit, combustion air/combustion-air treatment, charging system, etc., can solve problems such as reduced reliability, vibration problems, and heavy structural weight. , to improve reliability and life, save assembly time, and facilitate later maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

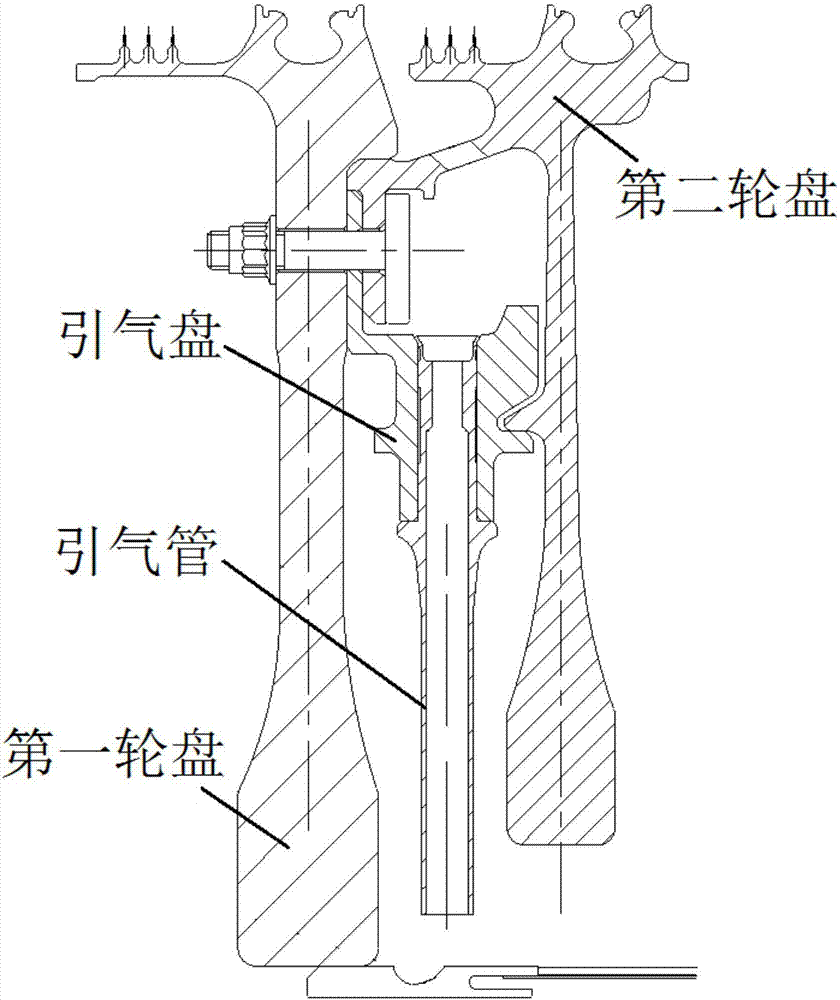

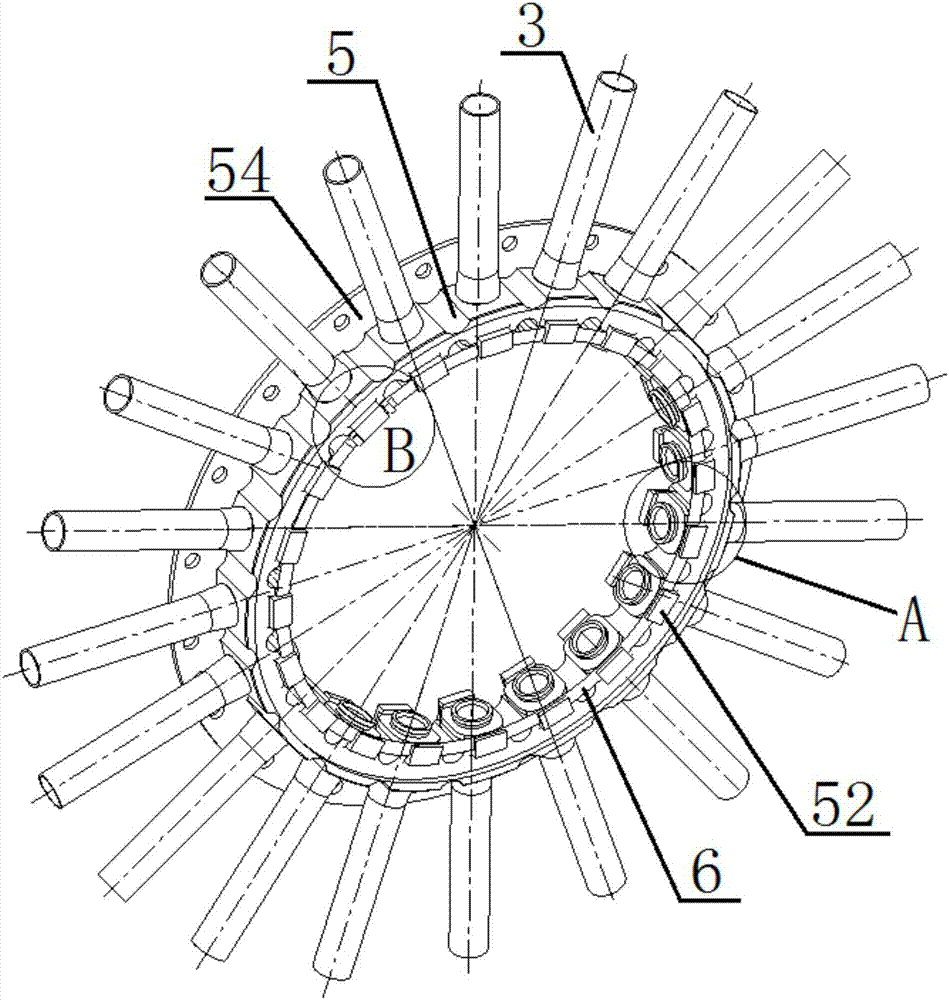

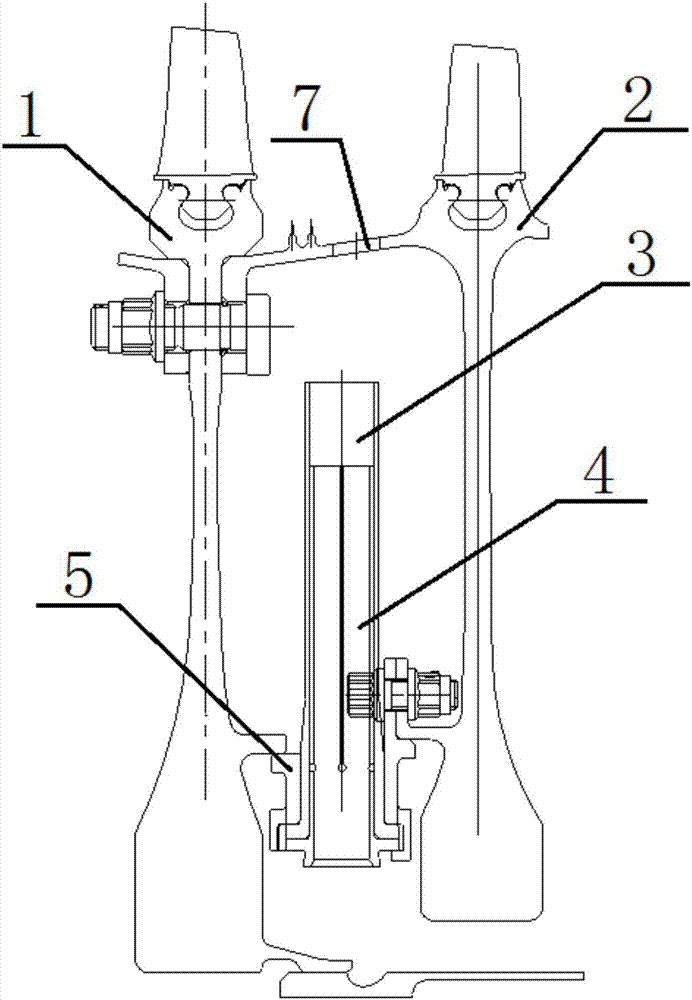

[0041] Such as figure 2 and image 3 As shown, the present invention provides a tube-type compressor rotor air-inducing device with damping, which is used to guide the air flow from the hub of the compressor to the hub, and the air-inducing device is installed and fixed on the first Between the disc 1 and the second disc 2, the air-inducing device includes an air-inducing pipe 3, a damping pipe 4 and an air-inducing disc 5;

[0042] The structure of the bleed pipe 3 is as Figure 4 and Figure 5 As shown, the bottom of the pipe wall of the air induction pipe 3 is provided with an air induction pipe flanging 31, and the structure of the damping pipe 4 is as follows: Image 6 and Figure 7 As shown, the tube wall of the damping tube 4 is coaxially provided with a damping tube protrusion 41. In the present embodiment, the flange 31 of the air-inducing tube and the protrusion 41 of the damping tube are all rectangular with rounded corners, and the flange 31 and the flange of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com