Preset up-regulation-position sleeve type lower rotational flow device

A swirl device, a casing type technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of affecting the living environment, potential safety hazards, hidden dangers of water leakage, etc., so as to improve the living environment, eliminate the Potential safety hazards and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

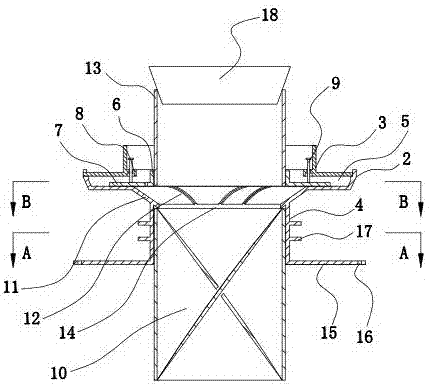

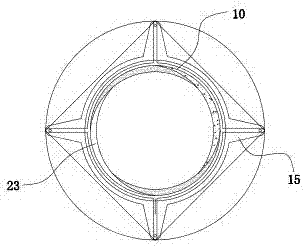

[0020] See attached Figures 1 to 5 , the preset upper-adjustment sleeve-type lower swirl device in the figure includes a water-stop sleeve 2 embedded in the floor concrete layer 1; where:

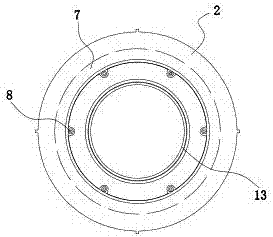

[0021] The water-stop casing 2 includes an upper casing 3 and a lower casing 4, the bottom of the upper casing 3 is bonded to the top of the lower casing 4, and the lower part of the upper casing 3 is connected to the lower casing. There is a displacement cavity 5 between the tops of 4, and the horizontal adjustment disc 7 of the displacement sealing tube 6 is located in the displacement cavity 5, and the longitudinal displacement adjustment connecting pipe 13 is fixed on the inner wall of the displacement sealing tube 6, and the horizontal adjustment disc 7 is provided with at least one water leakage hole;

[0022] The inner wall of the upper casing 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com