Heat induction defect detection method and system

A defect detection and heating technology, applied in the field of data processing, to achieve the effect of accurate and reliable judgment and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

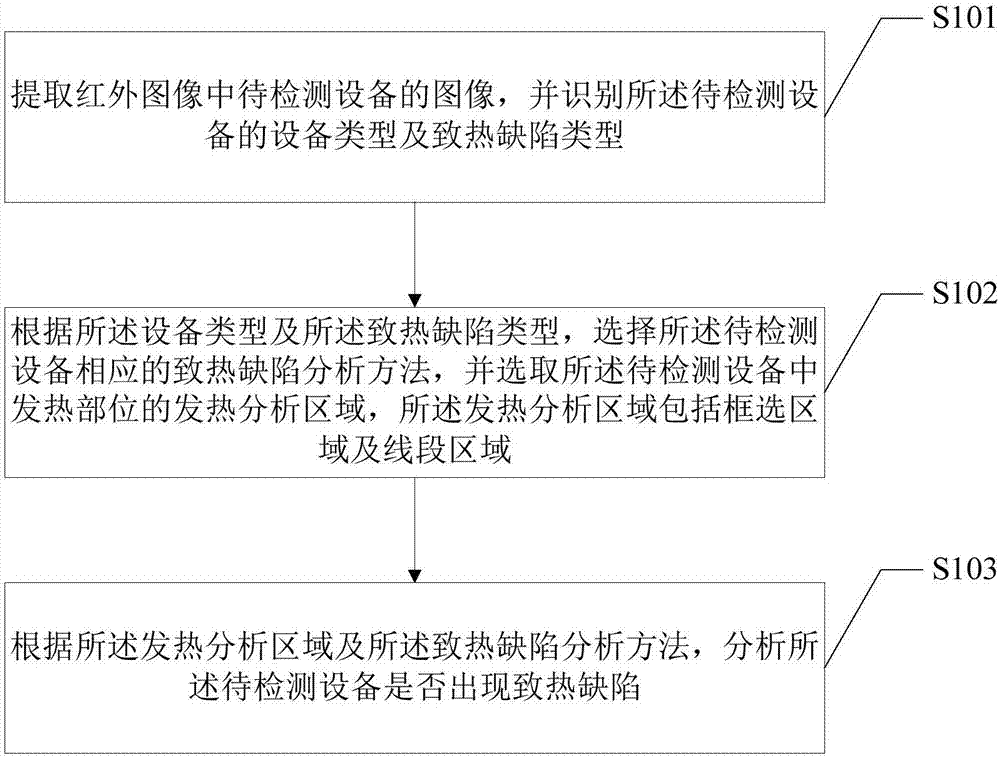

Method used

Image

Examples

Embodiment 2

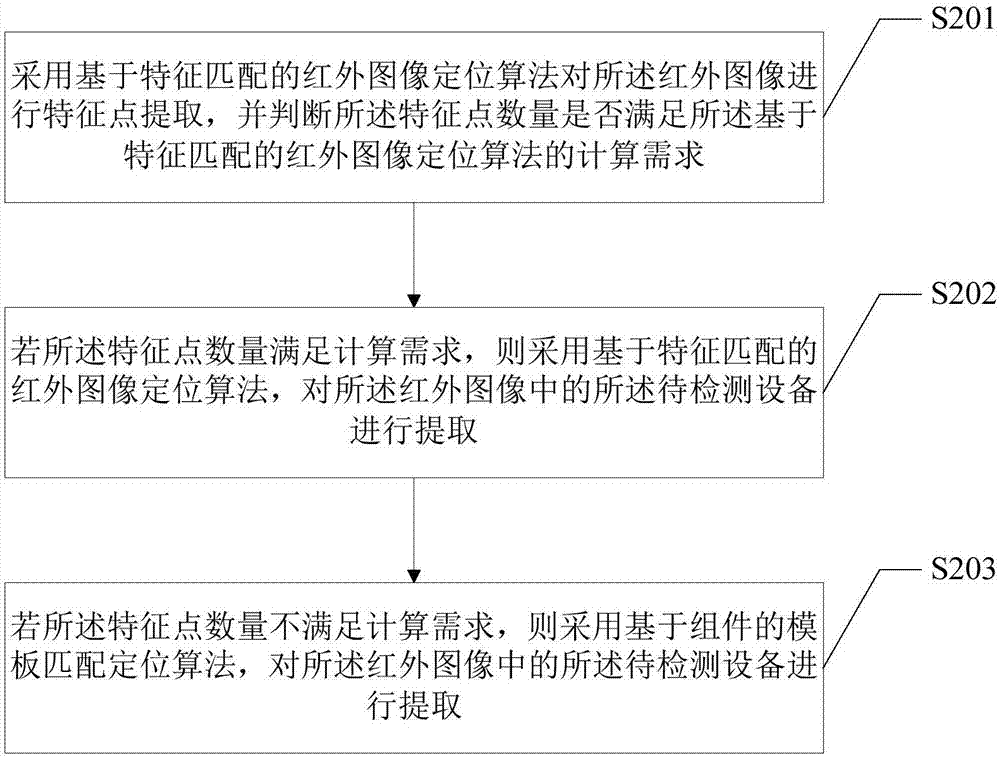

[0041] As a specific embodiment 2 of extracting the image of the device to be detected in the infrared image in step S101, including:

[0042] Step S201, using the infrared image positioning algorithm based on feature matching to extract feature points from the infrared image, and judging whether the number of feature points meets the calculation requirements of the infrared image positioning algorithm based on feature matching.

[0043] The infrared image positioning algorithm based on feature matching in this embodiment mainly includes a feature point collection part, a feature point matching part and a similarity judgment part, wherein the Surf algorithm is used as the algorithm of the feature point collection part. Since the Surf algorithm is a prior art, Not described in detail in this manual. For the feature point matching part, it is mainly used to judge whether the feature points collected in the infrared image have corresponding matching feature points in the referenc...

Embodiment 3

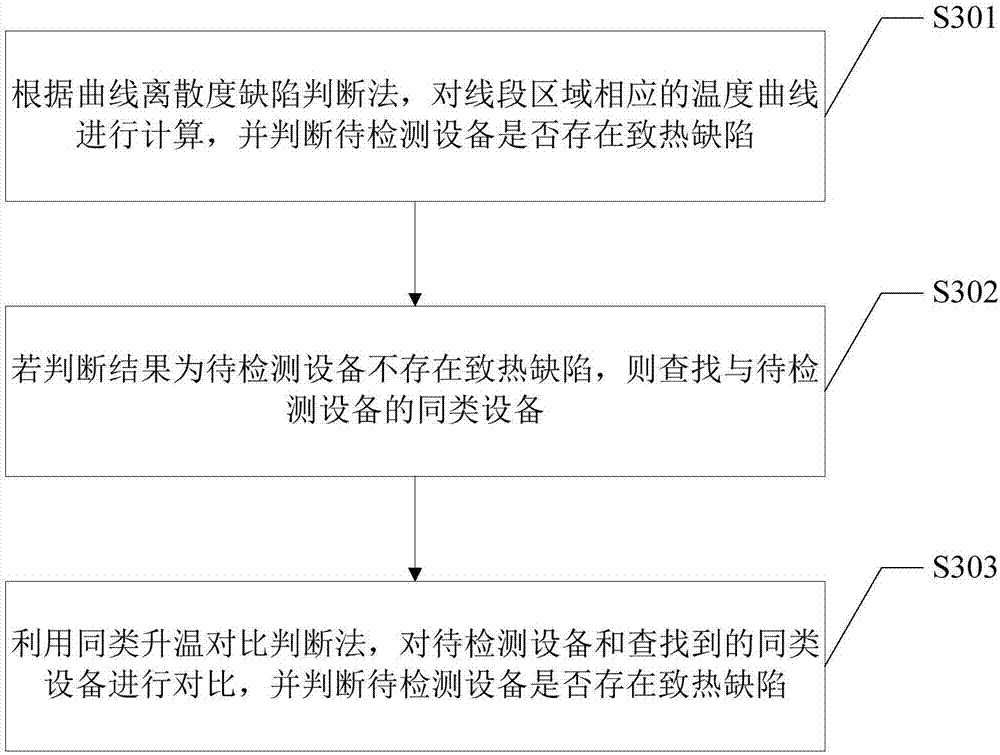

[0049] As another preferred specific embodiment 3 of step S102, it also includes:

[0050] If the type of equipment is non-multi-phase operation equipment, and the type of heating defect is voltage heating type, select the line segment area of the heating part in the equipment to be tested, and analyze the comprehensive curve dispersion defect judgment method and the similar temperature rise comparison judgment method, as a thermal defect analysis method. When it is identified that the equipment to be tested is not a multi-phase operation equipment and is a voltage-induced heating type equipment, in this embodiment, preferably, the line segment area is selected as the heating analysis area of the equipment to be tested, and the curve dispersion defect judgment method and similar methods are used. The comprehensive analysis of the temperature rise comparison judgment method is used as the analysis method of thermal defects, and the specific steps are as follows:

[0051] S...

Embodiment 4

[0055] As another preferred specific embodiment 4 of step S102, it also includes:

[0056] If the equipment type is multi-phase operation equipment, and the heating defect type is voltage heating type, select the line segment area of the heating part in the equipment to be tested, and comprehensively curve dispersion defect judgment method, curve similarity judgment method and similar temperature rise comparison The judgment method is used as the analysis method for thermal defects. The detailed steps are as follows:

[0057]Step S401, according to the curve dispersion defect judgment method, calculate the temperature curve corresponding to the line segment area, and judge whether there is a heating defect in the device to be tested. In the multi-phase operation equipment, the curve dispersion defect judgment method is used to analyze the thermal defect for each phase. For specific steps, see step S301 in Embodiment 3.

[0058] Step S402, if the result of step S401 is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com