Detection method and device for high-speed hydraulic generator rotor magnetic pole yoke t-tail groove

A technology of hydroelectric generator and rotor magnetic pole, applied in the direction of material magnetic variable, etc., can solve problems such as inability to clear out, reduce magnetic grade yoke insulation, and low signal-to-noise ratio, and achieve high reliability, high reliability, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

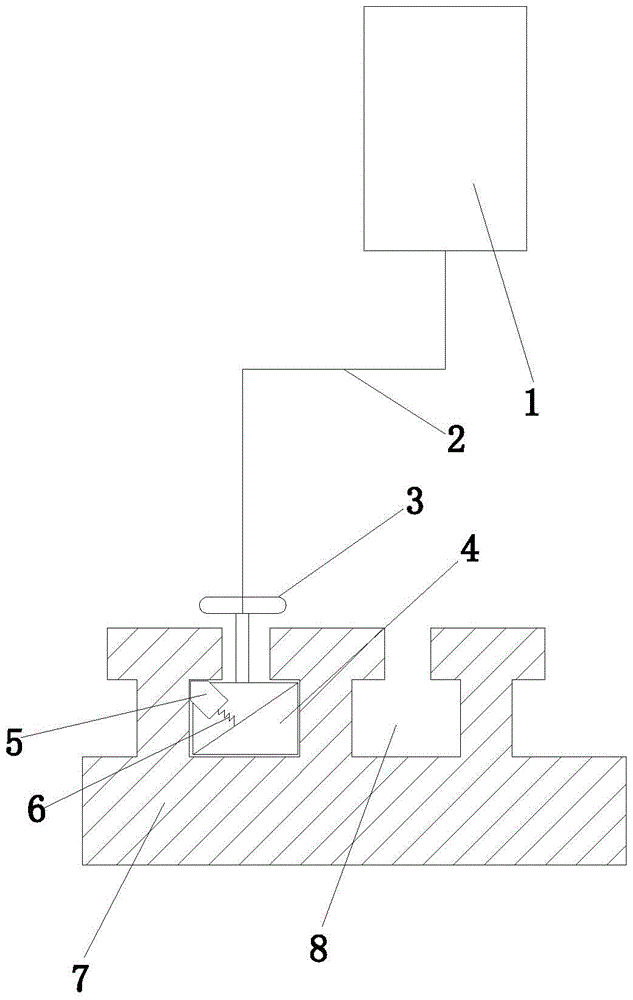

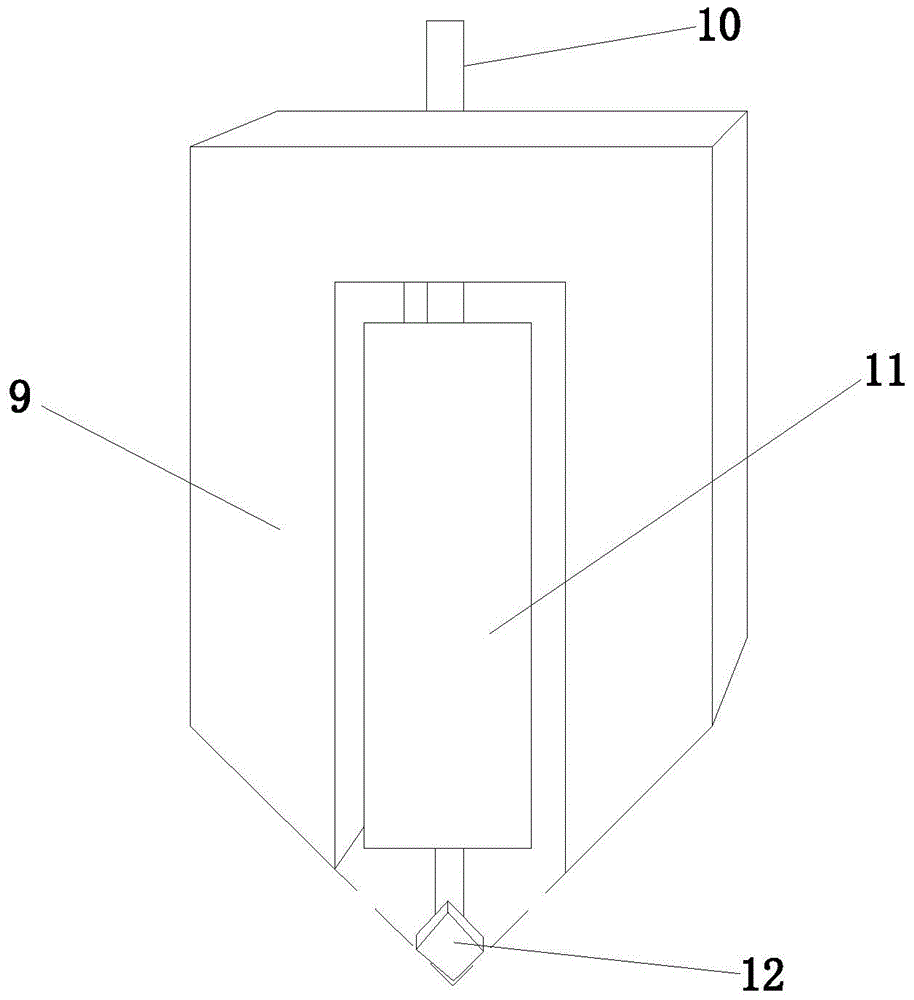

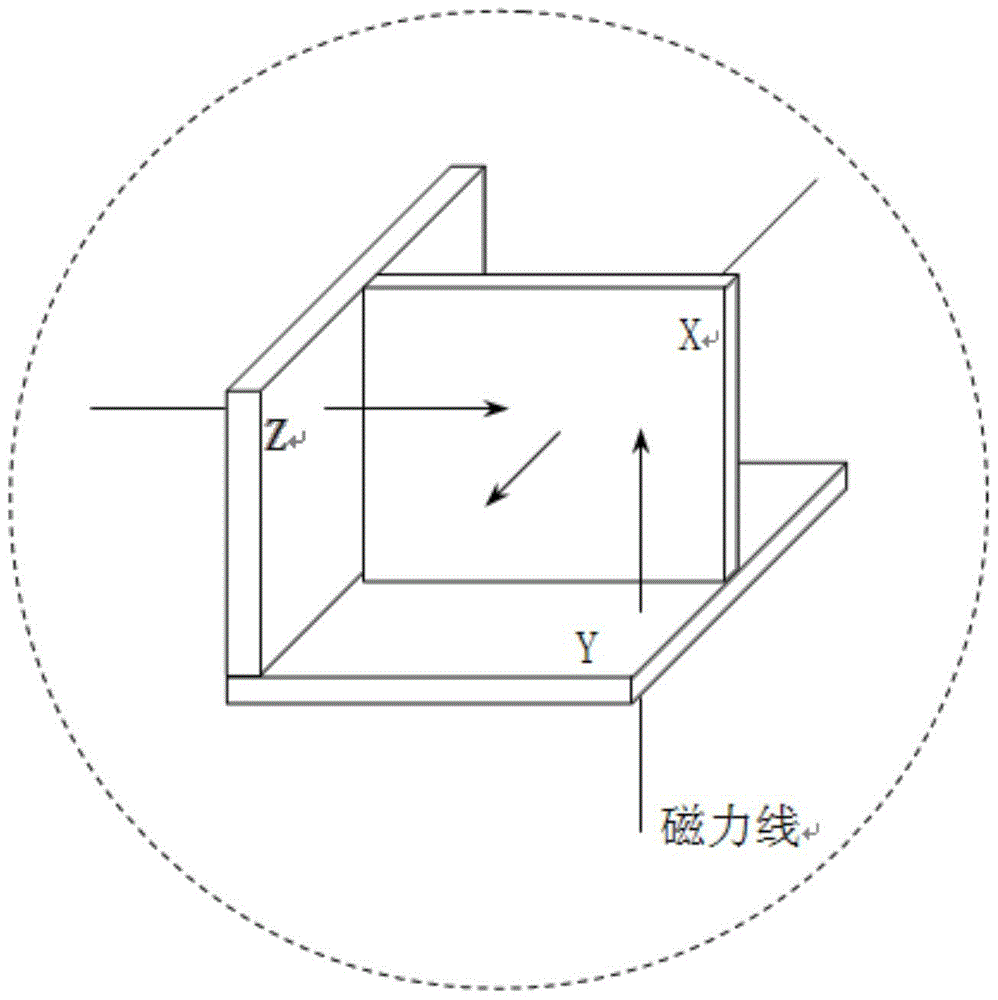

[0036] Example. The detection method of the rotor magnetic pole yoke T tail groove of the high-speed hydro-generator is to send the probe to the detection position through the probe guide bracket, and use the constant force structure to make the probe close to the surface under inspection. The laminated sheets generate an induced magnetic field. When the excited magnetic field lines encounter a crack at the tested position of the T-tail groove, a leakage magnetic field will be formed at the crack. The leakage magnetic field is received by the magnetic sensitive element in the probe and converted into a digital signal. The magnetic detector performs signal processing and display on the leakage magnetic field of the crack, so as to determine whether there is a crack in the checked T tail groove.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com