Method for rapidly judging elution start point and terminal point during macroporous resin absorption and separation process of salvianic acid A sodium and applications thereof

A technology of danshensu sodium and macroporous resin, which is applied in the field of quality inspection of traditional Chinese medicine production, can solve the problems of excessive eluent consumption and long elution time, and achieve low detection cost, fast and simple judgment process, and fast measurement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] As a preferred embodiment of the present invention, the elution process of Danshensu sodium extract comprises the following steps:

[0065] After the danshensu sodium extract is absorbed by the macroporous resin, it is washed with purified water, and at the same time when the danshensu sodium effluent is collected, the danshensu sodium effluent is sampled and separated every 1 to 10 minutes to obtain Different batches of danshensu sodium effluent.

[0066] Since the danshensu sodium extract is easily soluble in water, purified water can be used for elution, and the danshensu sodium effluent obtained at this time can also be called danshensu sodium washing solution. Wherein, typical but non-limiting time intervals for sample collection are 1 min, 2 min, 3 min, 4 min, 5 min, 6 min, 7 min, 8 min, 9 min or 10 min.

[0067] As a preferred embodiment of the present invention, during the elution process of the danshensu sodium extract, the danshensu sodium extract is absorbed...

Embodiment 1

[0085] A method for quickly judging the elution start point and end point of the danshensu sodium extract in the macroporous resin adsorption separation process provided in this embodiment includes the following steps:

[0086] (1) Raw material processing: 300kg of salvia miltiorrhiza medicinal material is physically obtained to obtain its decoction pieces;

[0087] (2) Process treatment: Danshensu decoction pieces were produced and prepared according to actual production requirements, and Danshensu sodium extract was absorbed by macroporous resin, then washed with 6BV purified water at a flow rate of 6BV / h, collect samples of the danshensu sodium effluent every 2 minutes, pass through a 0.45 μm microporous membrane, and seal and store different batches of danshensu sodium effluent;

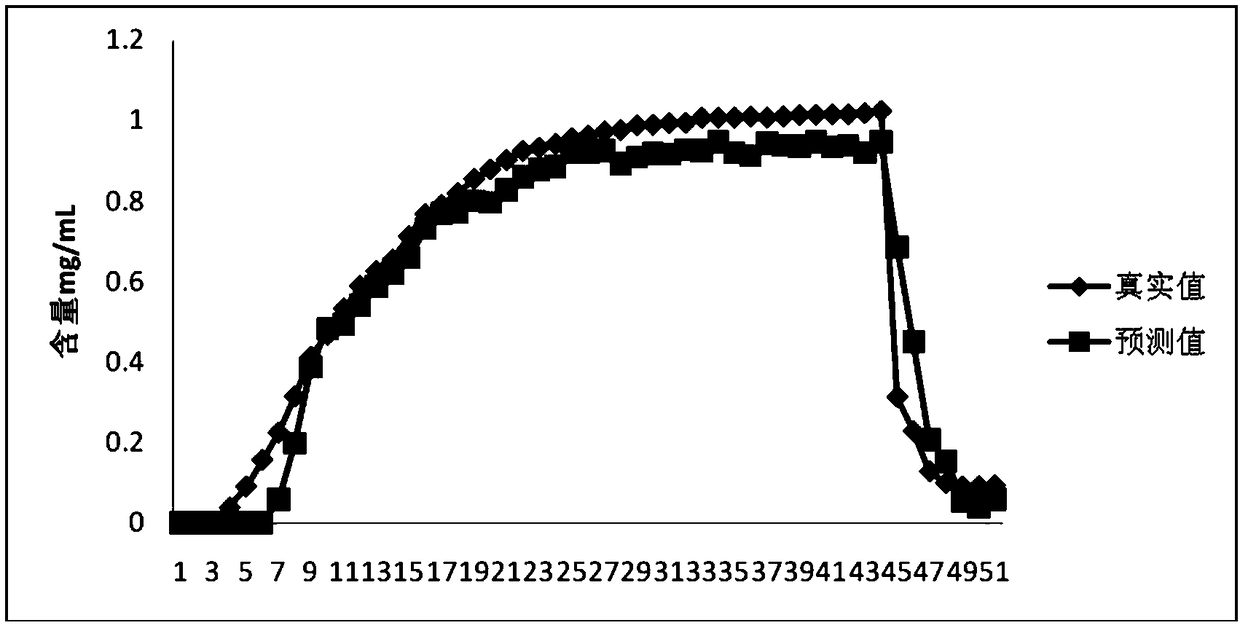

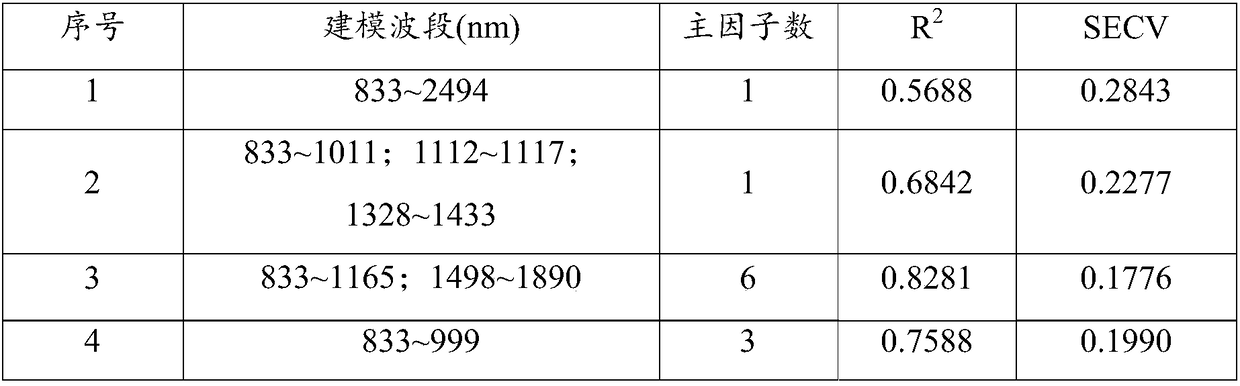

[0088] (3) Establishment of the calibration model: different batches of danshensu sodium effluent obtained from the elution process of the danshensu sodium extract were selected as samples to fo...

Embodiment 2

[0115] A method for quickly judging the elution start point and end point of the danshensu sodium extract in the macroporous resin adsorption separation process provided in this embodiment includes the following steps:

[0116] (1) Raw material processing: 300kg of salvia miltiorrhiza medicinal material is physically obtained to obtain its decoction pieces;

[0117] (2) Process treatment: Danshensu decoction pieces were produced and prepared according to the actual production requirements, and the Danshensu sodium extract was absorbed by macroporous resin, and then washed with 12BV purified water at a flow rate of 12BV / h, collect samples of the danshensu sodium effluent every 8 minutes, pass through a 0.45 μm microporous membrane, and seal and store different batches of danshensu sodium effluent;

[0118] (3) Establishment of the calibration model: different batches of danshensu sodium effluent obtained from the elution process of the danshensu sodium extract were selected as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com