Method for measuring acid-soluble copper in copper ore

An acid-soluble, sulfuric acid solution technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of production disconnection, long measurement time, poor control of reproducibility, etc., to achieve high repeatability and reproducibility, high accuracy , the effect of shortening the measurement time

Inactive Publication Date: 2018-11-23

WANBAO MINING

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing determination methods are based on the determination method of copper oxide in copper phase analysis, which has the disadvantages of long measurement time, poor control of reproducibility when the content of acid-soluble copper is high, and disconnection from production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0055] Using this method, two standard samples, GBM915-8 and GBM303-2, were tested for acid-soluble copper for repeatability and reproducibility detection;

[0056]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

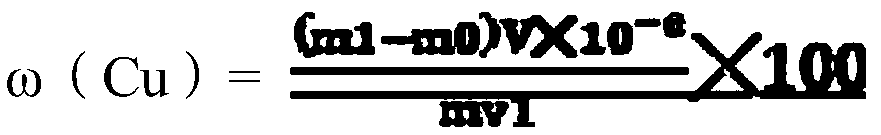

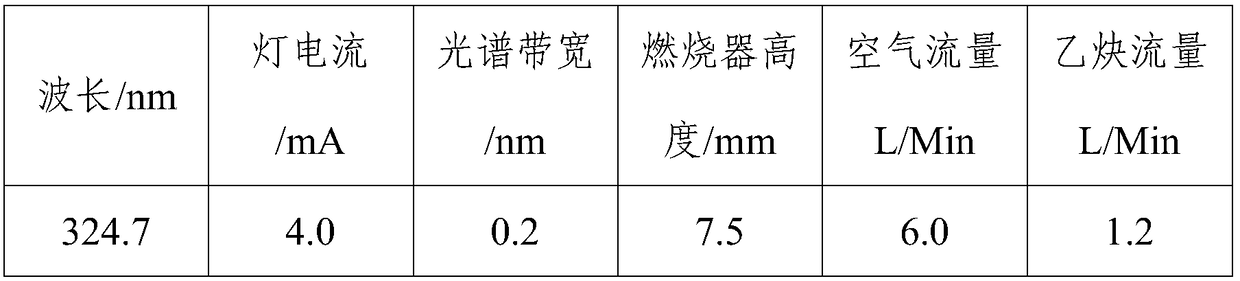

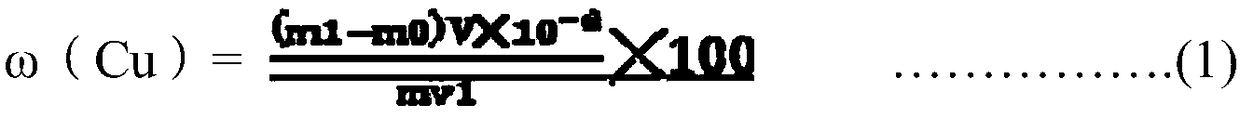

The invention provides a method which can quickly measure content of acid-soluble copper in copper ore. After weighing of the ore, 5% of sulphuric acid and sodium sulfite are added into the ore. Furthermore after oscillation on an oscillator for one hour, filtrate is filtered and volume is fixed. Then 5% sulfuric acid medium copper solution is prepared and is measured in an atomic absorption spectrophotometer, thereby greatly shortening testing time and improving testing repeatability and reproducibility. The method can accurately reflect content of sulphuric acid leached copper in producing ore or copper concrete. The method for measuring the acid-soluble copper has advantages of effectively shortening measuring time, preventing a problem of inaccurate measurement caused by overlong sulphuric acid smoking time and solution sputtering because of overhigh temperature in a smoking process, measuring the acid-soluble copper in different copper ore standard samples in China and other countries, and realizing relatively high accuracy.

Description

technical field [0001] The invention belongs to the field of rock ore testing, and in particular relates to a method capable of quickly measuring the content of acid-soluble copper in copper ore. Background technique [0002] Congo (gold) copper ore resources in Africa are relatively rich, and most of them are sulfur-oxygen mixed copper ore. When this type of copper ore is treated by flotation and acid leaching, the content of acid-soluble copper in the ore has a greater impact on the beneficiation and smelting performance of the ore. Large is an important indicator that needs to be mastered. The existing determination methods all follow the determination method of copper oxide in copper phase analysis, which has the disadvantages of long measurement time, poor control of reproducibility when the content of acid-soluble copper is high, and disconnection from production. Contents of the invention [0003] The object of the present invention is to provide a kind of assay me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/31

CPCG01N21/31

Inventor 陈普段景文王振堂彭建平

Owner WANBAO MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com