Non-contact power supplying device and elevator

A non-contact power supply and current value technology, applied in the direction of circuit devices, electrical components, etc., can solve problems such as unbearable self-weight, power supply of equipment in the car, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

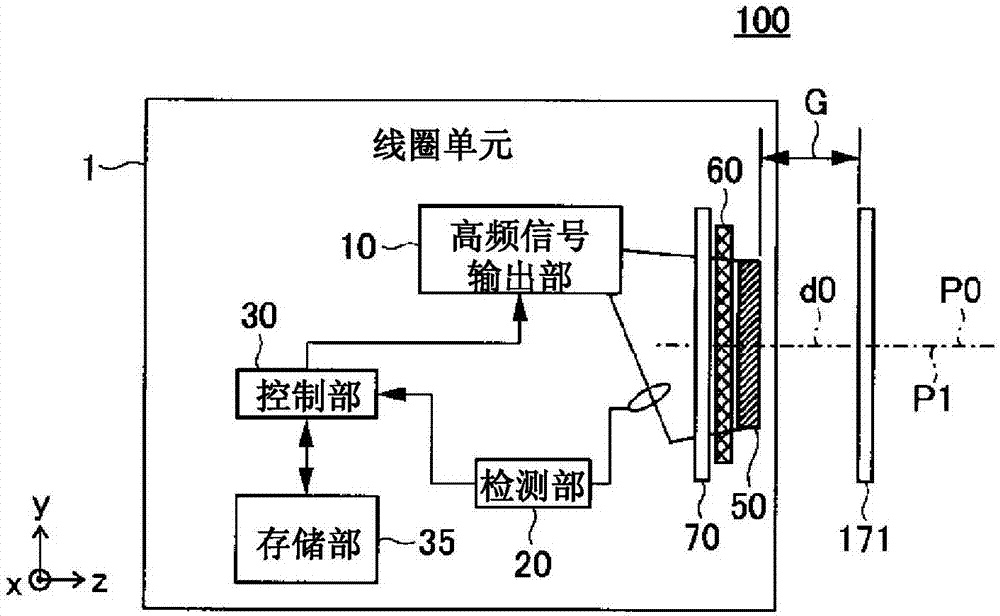

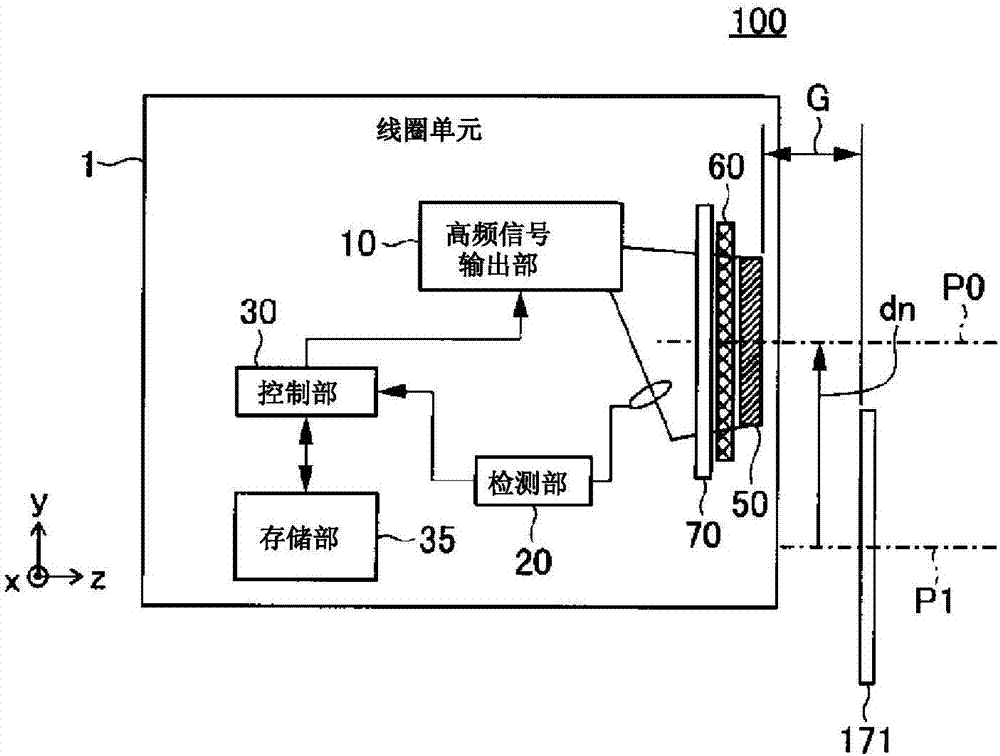

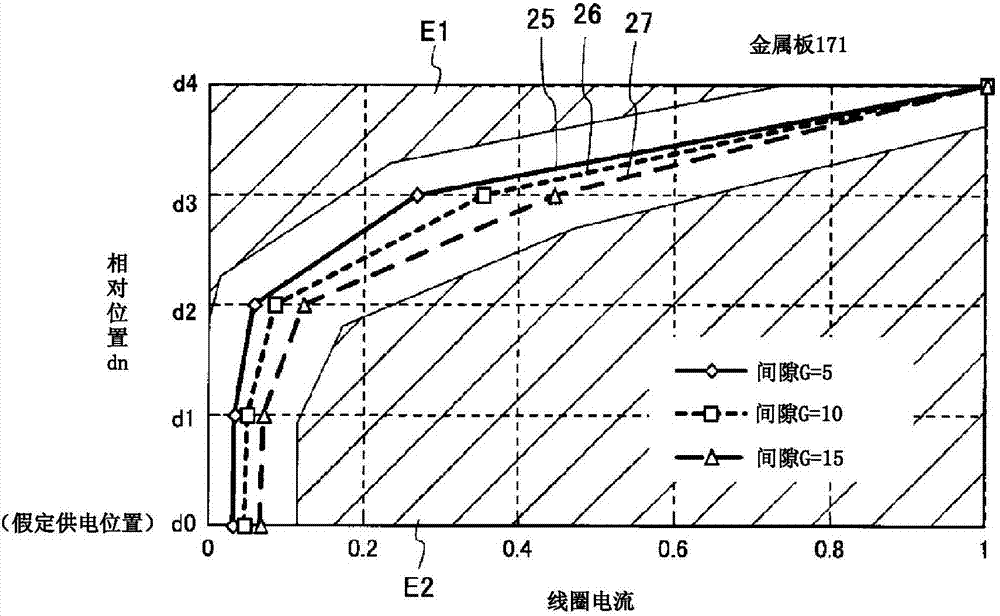

[0037] figure 1 It is a schematic configuration diagram of the contactless power supply device according to the first embodiment of the present invention. refer to figure 1 The non-contact power supply device will be described.

[0038] figure 1 The illustrated wireless power supply device 100 includes a coil unit 1 and a metal plate 171 that perform a power receiving function for wireless power supply. The coil unit 1 is configured to be movable. figure 1 In, the moving direction of the coil unit 1 is set as the first direction (y direction), the direction perpendicular to the first direction is set as the second direction (x direction), and the direction perpendicular to the first direction and the second direction is set as The direction is set to the third direction (z direction).

[0039] The coil unit 1 includes a high-frequency signal output unit 10 , a detection unit 20 , a control unit 30 , a storage unit 35 , a coil 50 , a magnetic body 60 , and a shield plate 7...

no. 2 approach

[0067] Next, an example of an elevator (elevator) provided with the contactless power supply device of the first embodiment will be described as a second embodiment.

[0068] Figure 4 It is a schematic block diagram of the elevator of 2nd Embodiment. Figure 4 The elevator 200 of is provided with the contactless power supply device of the first embodiment. The elevator 200 includes a hoistway 80 formed in a building structure, a car 2 (an example of a mobile body) on which a user rides, a traction machine 3, a counterweight 4, and a suspension coil wound around the traction machine 3. The car 2 and the main hoist 5 of the counterweight 4.

[0069] The hoistway 80 is formed in the building structure, and the machine room 82 is installed on the top thereof. The hoisting machine 3 is disposed in the machine room 82 , and a motor (not shown) rotates forward or reverse to wind the main rope 5 , thereby raising and lowering the car 2 . The car 2 is guided up and down in the y d...

no. 3 approach

[0115] Next, an example in which the position of an elevator is detected using the contactless power supply device of the present invention will be described as a third embodiment. In this embodiment, the position of the coil 50 on the moving path (in the hoistway 80 ) is detected by providing metal plates with different shapes on the moving path (each floor) of the car 2 .

[0116] Figure 9 It is a schematic block diagram of the elevator of 3rd Embodiment.

[0117] The first floor (1F) of the elevator 200 is a power supply floor where the coil unit 101 is installed, and the metal plate 171 is installed. A metal plate 172 is installed on the second floor (2F), a metal plate 173 is installed on the third floor (3F), and a metal plate 177 is installed on the first basement floor (B1). The metal plates 171, 172, 173, and 177 have different shapes, respectively.

[0118] Figure 10 It is a figure which shows the example of the shape of metal plate 172,173,177.

[0119] Seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com