SO3 removing system and method based on fine particles of alkaline absorbent

A technology of fine particles and absorbents, applied in the field of SO3 removal systems based on fine particles of alkaline absorbents, can solve the problems of poor dispersion uniformity of alkaline absorbent particles, high operating costs, and low utilization of alkaline absorbents, etc. , to achieve the effect of improving energy utilization, reducing operating costs and reducing waste

Pending Publication Date: 2017-08-11

BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The technical problem to be solved is: the existing SO removal in the flue gas 3 or high operating costs, or the problems of dust accumulation, corrosion and cloggi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

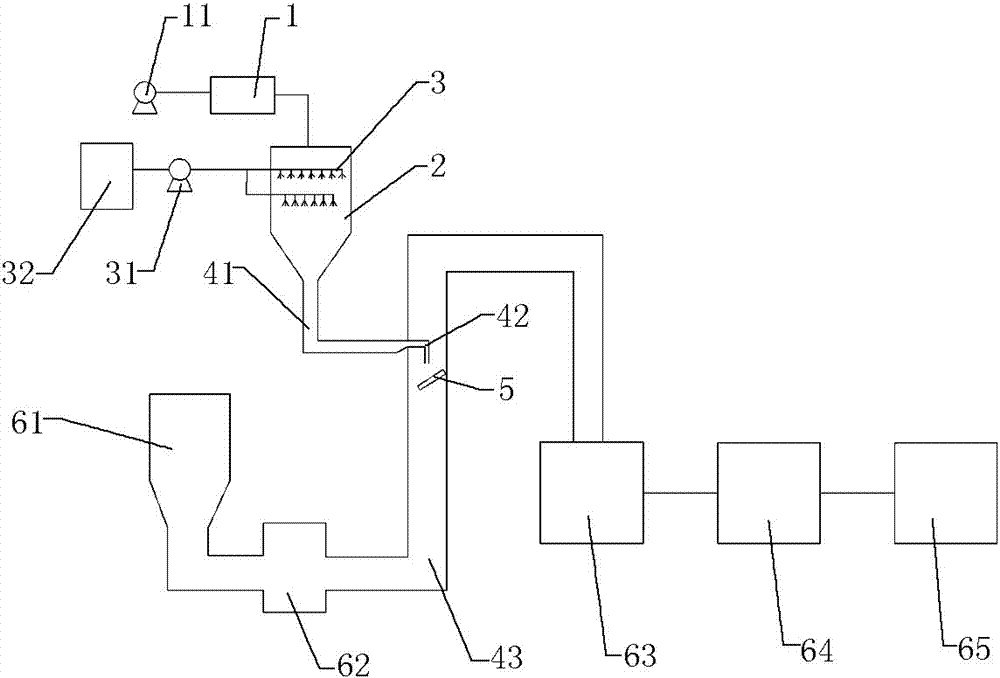

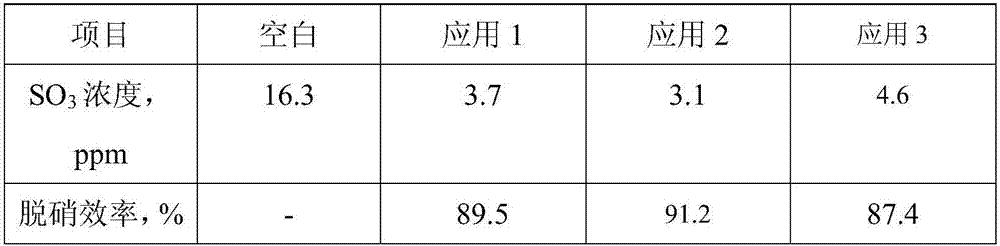

The invention discloses a SO3 removing system and method based on fine particles of an alkaline absorbent, belonging to the technical field of removal of SO3 from flue gas. According to the invention, the air inlet of an air heater is communicated with a fan while the air outlet of the air heater is communicated with the air inlet of a urea pyrolyzing furnace; mixed solution spray guns are uniformly arranged below the air inlet of the urea pyrolyzing furnace and connected with a solution storage tank via a transfer pump; a mixed solution in the solution storage tank is composed of urea and the alkaline absorbent; the other end of a pyrolysis gas pipeline is connected with a coal-fired flue gas flue via an ammonia spraying pipe; a vortex mixer is obliquely arranged below the gas outlet of the ammonia spraying pipe; the gas inlet of the coal-fired flue gas flue is connected with the flue gas outlet of a coal economizer; and the gas outlet of the coal-fired flue gas flue is connected with a SCR reactor. The SO3 removing system and method provided by the invention can improve the utilization rate of energy, use the alkaline absorbent with fine particle size, do not need extra equipment and are low in operation cost.

Description

technical field [0001] The invention relates to flue gas deSO 3 System technology field, especially related to a kind of SO2 based on fine particles of alkaline absorbent 3 Removal system and removal method thereof. Background technique [0002] The flue gas produced by coal combustion contains a certain concentration of SO 2 and SO 3 , where SO 2 It is produced by burning coal in a boiler with a concentration of 1500-18000 mg / m 3 , mainly concentrated in 3000~6000mg / m 3 ; while SO 3 It comes from two parts, one part is produced by direct combustion in the boiler, and its concentration accounts for about 2 0.5%-1.5% of the concentration; the other part is SO 2 After passing through the SCR denitrification reactor, it is oxidized to SO 3 , the conversion rate of this part accounts for about SO 2 0.5%-1.5% of the concentration. Therefore, in the flue gas at the outlet of the SCR reactor, SO 3 The concentration accounts for about SO 2 1%-3% of the concentration. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/83B01D53/50B01D53/46

CPCB01D53/46B01D53/508B01D53/83B01D2258/0283B01D2257/302B01D2257/80B01D2251/306B01D2251/304

Inventor 郑鹏王洪亮唐坚路光杰姚宣

Owner BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com