Cutting structure for submarine gate of injection mold

A latent gate, injection mold technology, applied in the field of injection mold gate cutting, can solve the problems of affecting the appearance quality of products, time-consuming and laborious, and easy to produce cold grains on the surface of products, so as to save the cost of mold test and avoid modification. , The effect of reducing the number of mold trials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

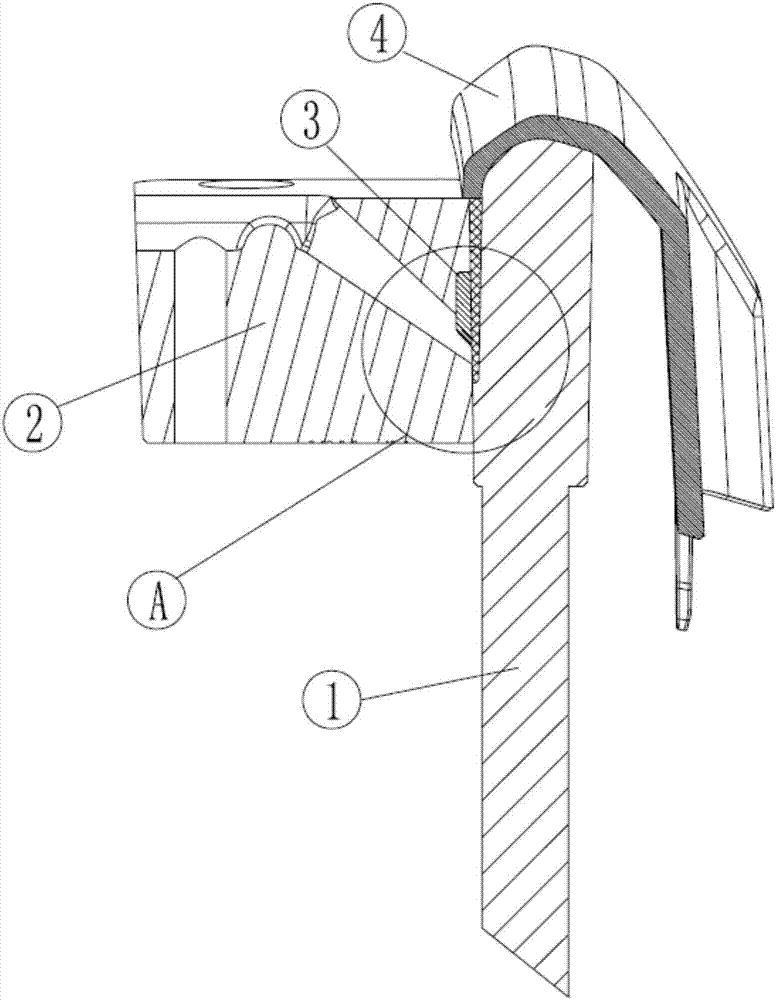

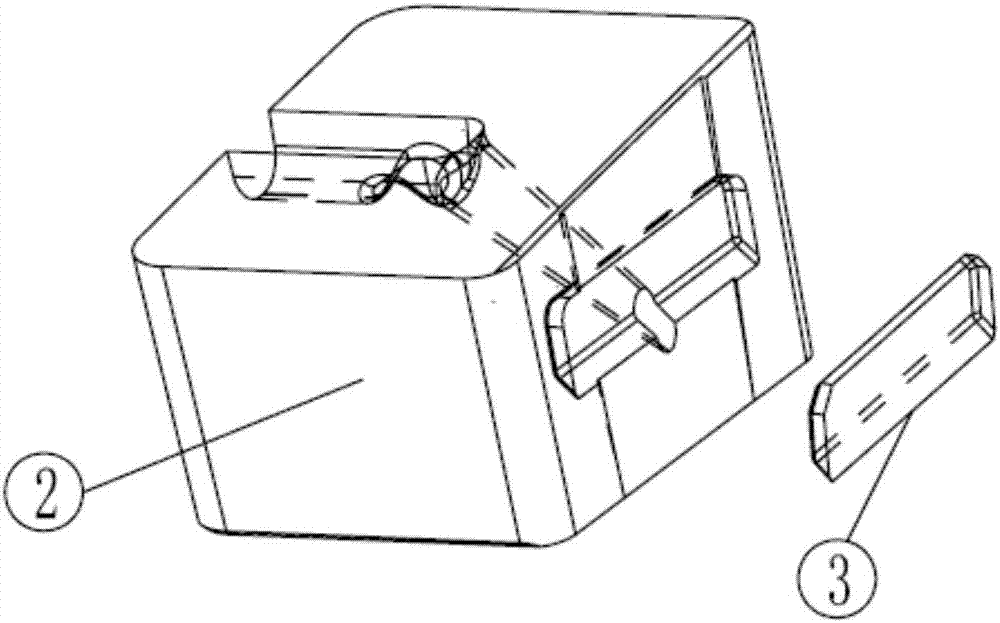

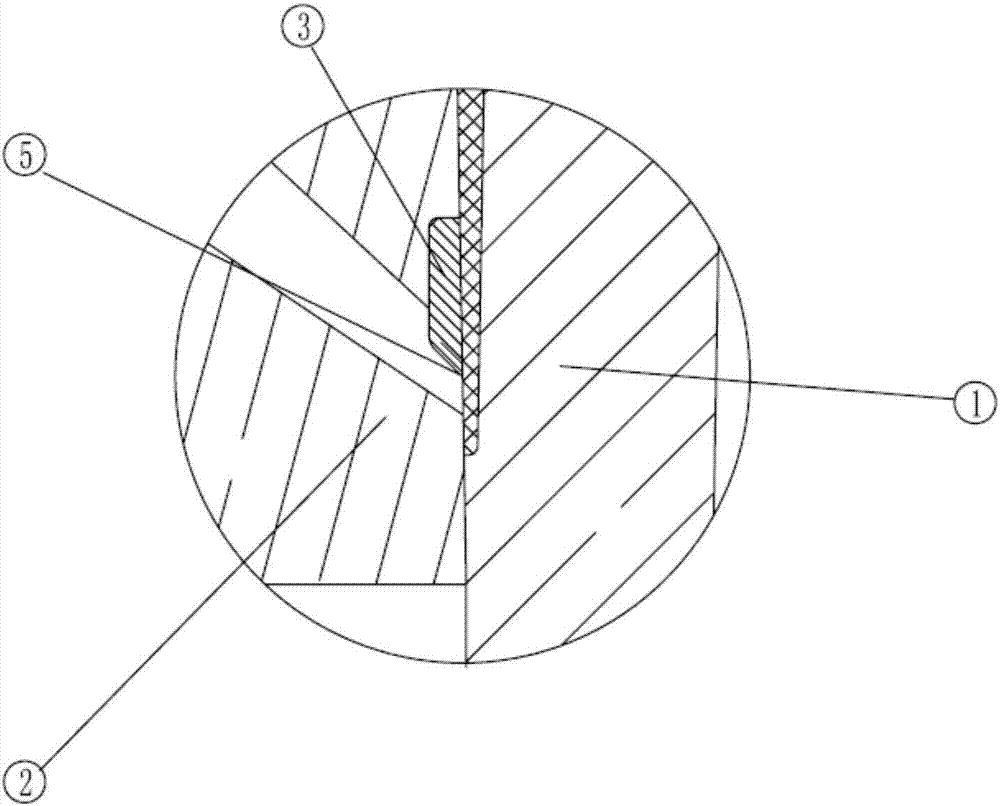

[0024] When the injection mold is producing products, the plastic melt in the molten state is first injected into the cavity of the injection mold through the injection molding machine. Usually, the plastic melt enters the mold cavity from the injection port. In this technology, the plastic melt from The runner hole on the latent gate insert 2 enters the latent gate insert 2, and passes through the gate runner in the latent gate insert 2 from the tool on the side of the latent gate insert 2 The installation groove flows out, and enters the cavity of the injection mold through the runner gap, and then waits for the plastic product 4 to cool and form. After the plastic product 4 is cooled and formed, the mold is opened, and then the straight ejector rod 1 is started to eject the plastic product 4. The cutting edge 5 of the cutter 3 on the latent gate insert 2 cutter mounting groove will cut off the gate and the plastic product 4, so as to prevent the gate and the plastic product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com