Packing box

A packaging box and box body technology, applied in the field of packaging, can solve the problems of increasing raw material and labor costs, low packaging efficiency, and poor fixing effect, and achieve the effects of excellent buffering capacity, excellent anti-collision, and improved packing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

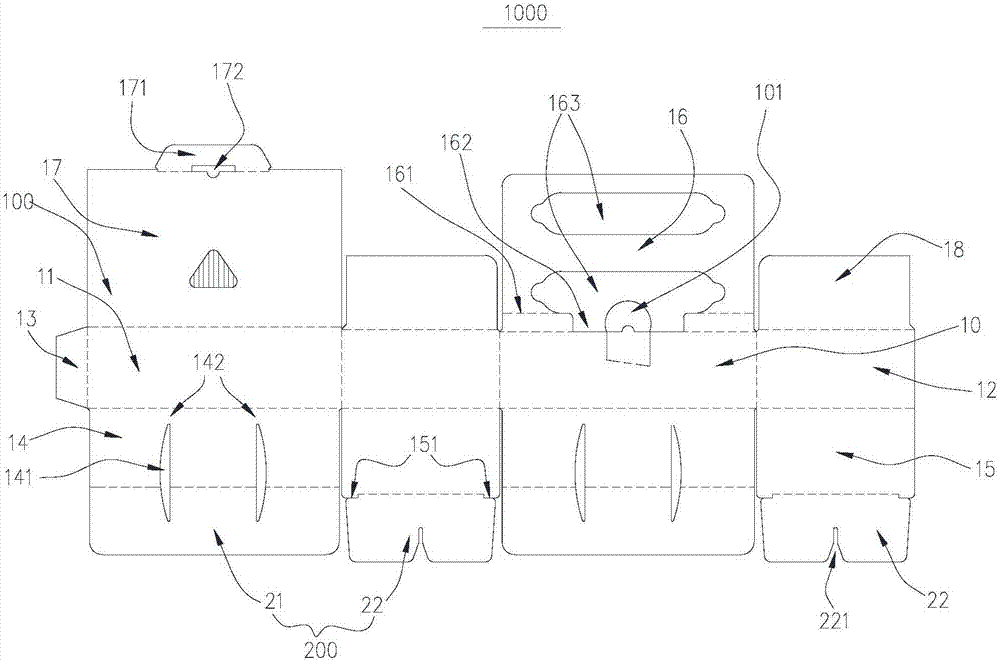

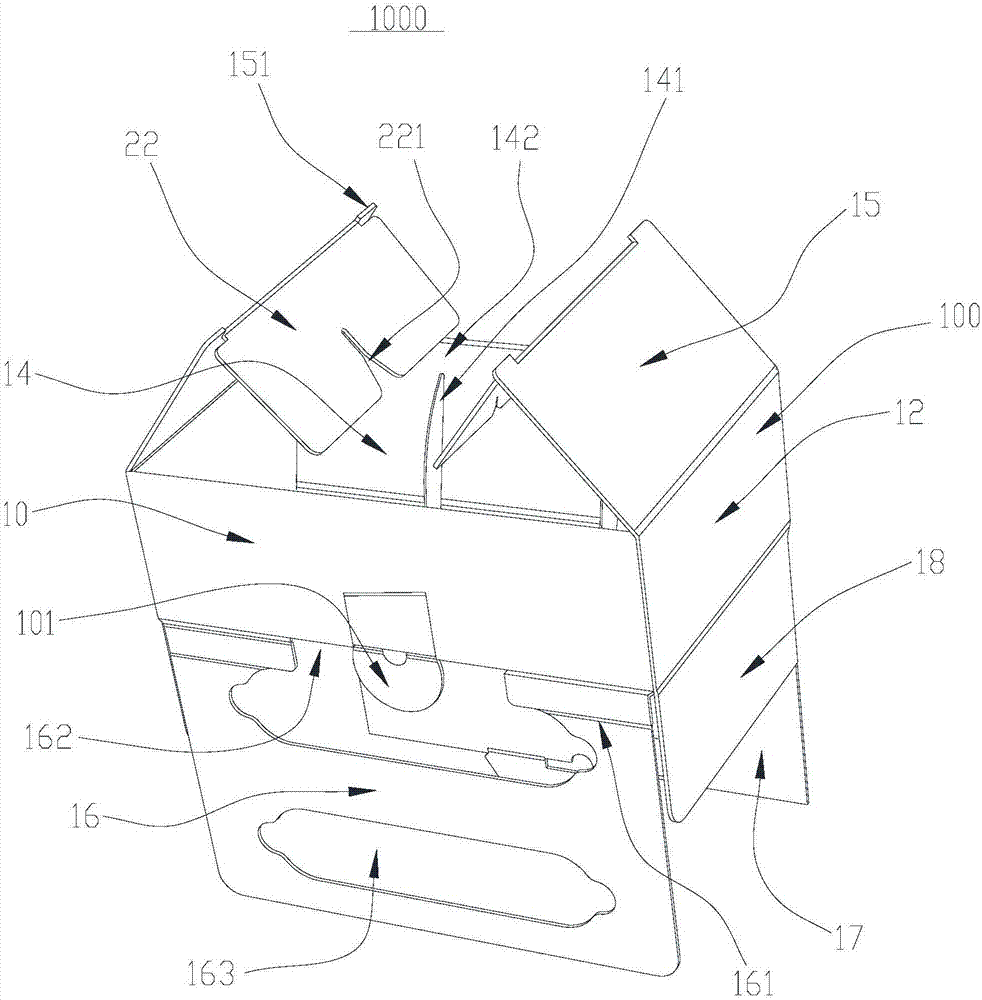

[0028] Such as figure 1 , figure 2 As shown, the packaging box 1000 includes a box body 100 and a self-contained paper card 200 placed in the box body 100 and integrally formed with the box body 100 to improve packaging efficiency and reduce costs.

[0029] The box body 100 includes a wall (not numbered, the same below) consisting of a front end plate 10, a rear end plate 11, two side plates 12, and a paste head 13, and a top cover (not numbered, the same below) that is respectively packaged at the upper and lower ends of the wall. Same), bottom plate (unlabeled, the same below). The self-contained paper card 200 is formed by extending from the end of the bottom plate and can be bent inward and vertically supported in the box body 100 .

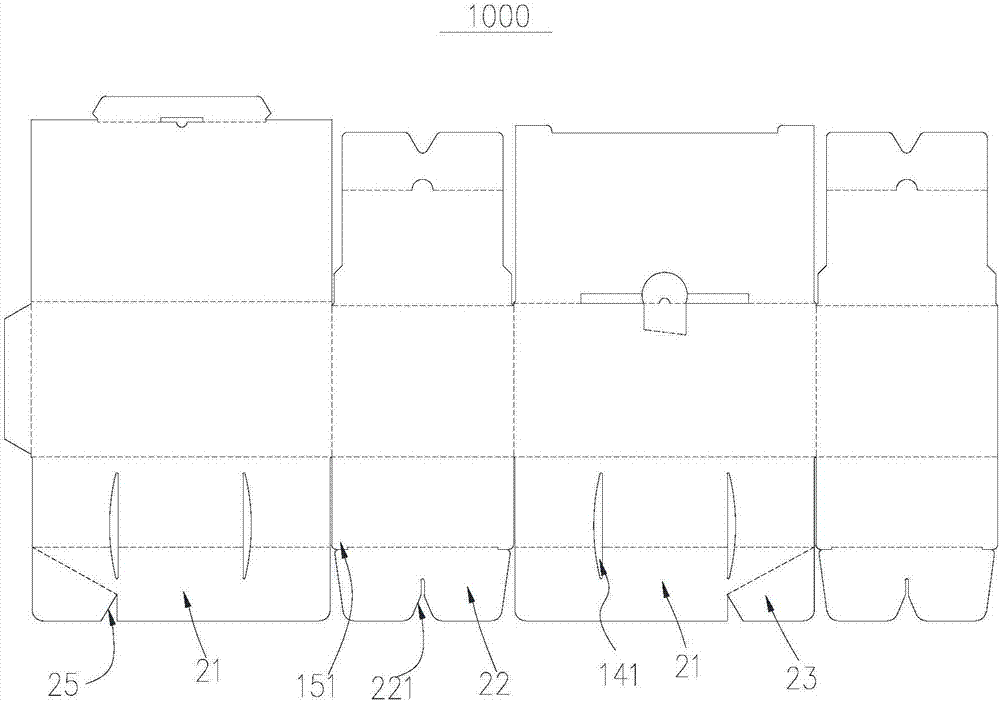

[0030] refer to figure 1 As shown in the expanded view, the bottom plate includes a lower cover plate 14 connected to the front and rear end plates 10 and 11 and a lower flap 15 connected to the two side plates 12 respectively.

[0031] ...

Embodiment 2

[0042] In order to adapt to the placement and support of more accessories, the present invention also modifies the self-contained paper card so that it can divide the space inside the box into more areas. In this embodiment, the packaging box is similar to that of Embodiment 1, the difference lies in that the end of the lower cover extends to form a board with the same width as the lower cover, on which there are holes extending from the first guide groove. corresponding to the position of the slot, a V-shaped cut is made from the end of the plate, and the root of the cut is at a certain distance from the end of the slot, so that it can be moved along the fold line defined by the root of the cut to the apex of the lower cover plate. The third self-contained paper card is formed by inward bending, and the card board leans against one side of the second self-contained paper card. That is to say, in this embodiment, the first self-contained paper card and the third self-contained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com