A System for Online Replacement of Ceramic Rollers

A technology of ceramic rollers and ceramics, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass transportation equipment, etc. It can solve the problems of poor cooling effect and inapplicable on-line replacement of ceramic rollers, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

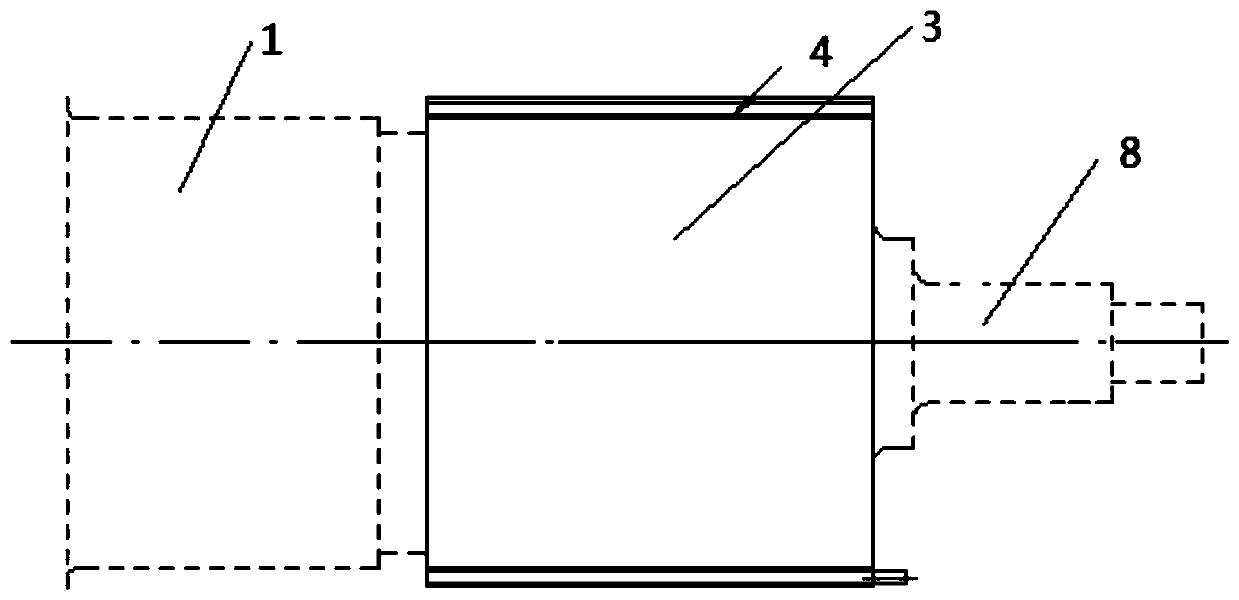

[0032] The ceramic roller 1 includes a ceramic roller body and metal roller heads 8 arranged at both ends of the ceramic roller body and cemented and fixedly connected with the ceramic roller body. The ceramic roller 1 passes through the inside of the slag box 5 and is erected on the slag box 5 .

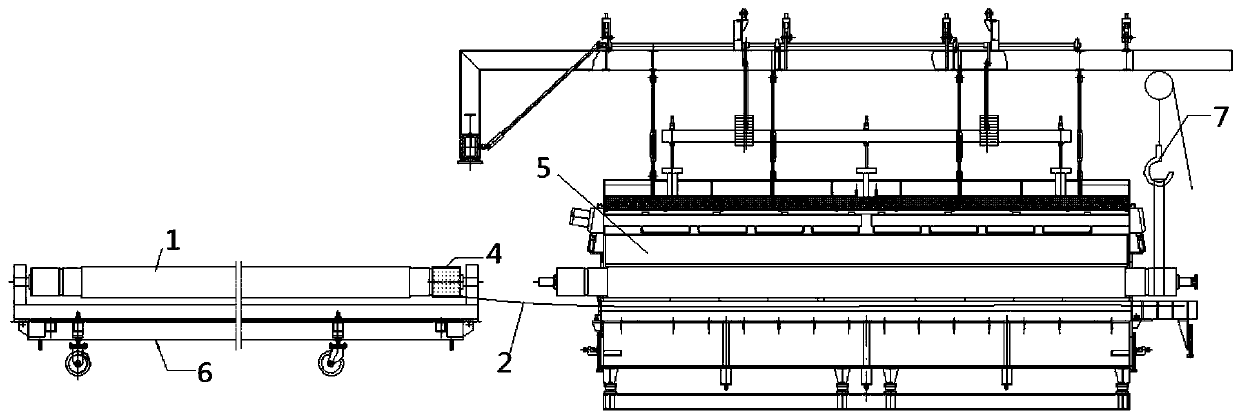

[0033] figure 1 Shown is the system for replacing the ceramic roller 1 on-line, which includes

[0034] The cooling device and the roller changing device, the cooling device is suitable for being set on the cementing part 3 of the ceramic roller 1 that needs to pass through the inside of the slag box 5 when changing ceramics; the roller changing device is used to pull the ceramic roller 1 out of the slag Box 5. The cooling device includes a cooling main body 4 arranged around the outside of the gluing part 3 and an air supply device for supplying cooling air.

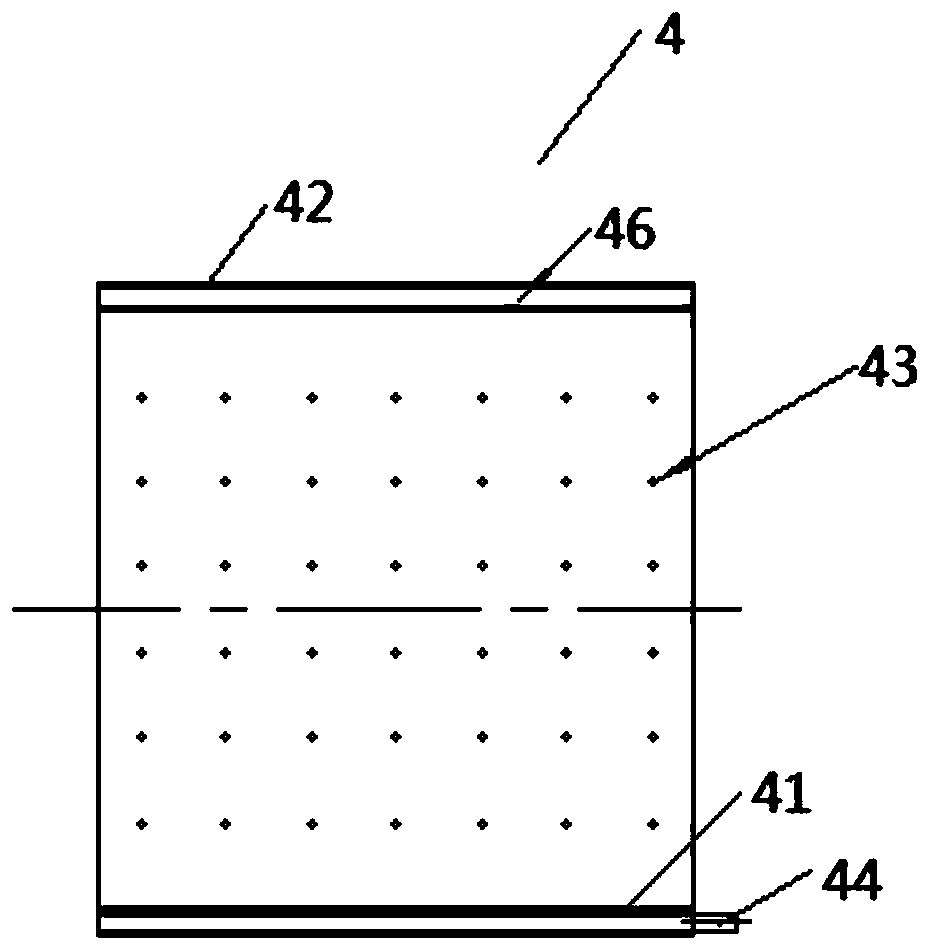

[0035] The cooling main body 4 is provided with an air inlet 44 and an air outlet 45 communicating with the air supply eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com