rail grinding machine

A grinding machine and rail technology, applied in the direction of rail, laying rail, rail maintenance, etc., can solve the problems of inability to directly adjust the grinding direction, inconvenient for continuous rail grinding, inconvenient transportation and use, etc., and achieve material saving, weight reduction, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

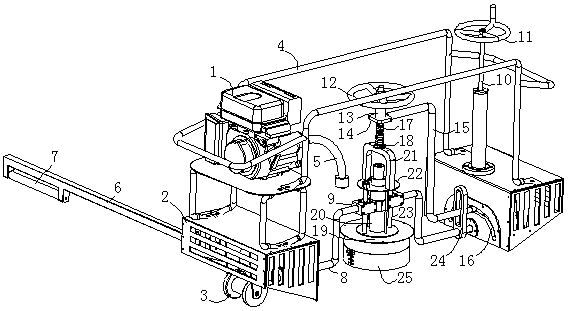

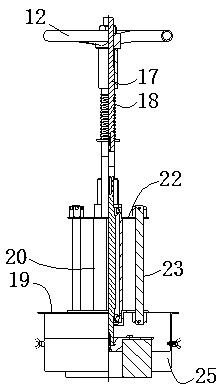

[0027] Specific implementation methods: such as Figure 1-2 As shown, a rail grinding machine includes a body, the body is provided with walking wheels for walking on the rail, the body is also provided with a grinding wheel device and a power machine 1, and the power machine 1 is connected to the grinding wheel device through a transmission mechanism; its characteristics are , the body includes two supporting shells 2 arranged side by side at intervals, and a running wheel 3 is arranged under the two supporting shells 2, and the two supporting shells 2 are fixedly connected as a whole through a connecting steel pipe 4, and the grinding wheel device A grinding wheel for rail grinding is arranged below, the lower surface of the grinding wheel is the grinding surface, and the grinding wheel device is installed between the two supporting shells through a rotation adjustment mechanism, which can adjust the grinding surface of the grinding wheel to rotate along the axis of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com