LED lamp panel printed with conductive ink, manufacturing technique of LED lamp panel, and integrated LED lamp for refrigerator

A technology of LED lamp panels and LED lamps, which can be applied in household appliances, semiconductor devices of light-emitting elements, applications, etc., can solve the problems of affecting processing efficiency, waste of copper raw materials, and corrosion of copper layers, so as to improve processing efficiency and reduce production Process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

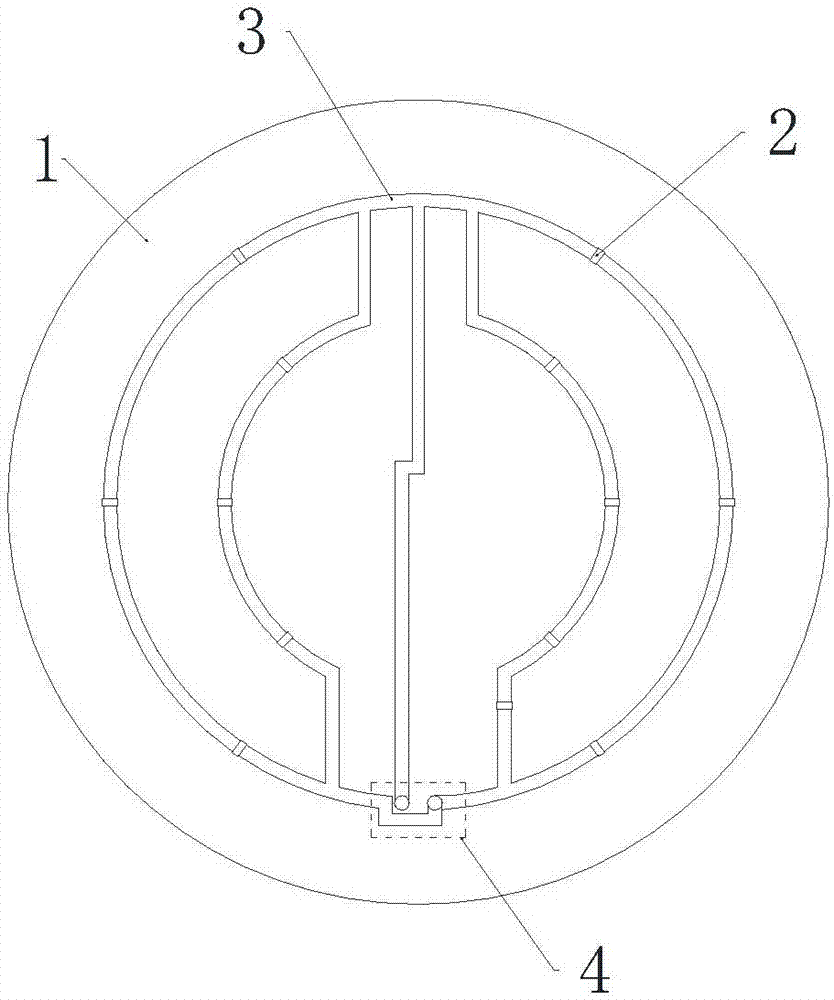

[0059] like figure 1 As shown, an LED lamp board printed with conductive ink includes an insulating carrier 1 on which several LED lamps 2 are fixed, and the insulating carrier 1 is provided with two poles in contact with the poles of each LED lamp 2 The conductive ink circuit 3, the insulating carrier 1 is also provided with the electrical conductor 4 which is in contact with the end of the conductive ink circuit 3.

[0060] Conductive ink is mainly composed of matrix resin and conductive filler, that is, conductive particles. The conductive particles can be combined to form a conductive path through the bonding effect of the matrix resin, and the conductive particles can be firmly attached to the insulating carrier 1 .

[0061] In this embodiment, the conductive ink circuit 3 can replace the traditional copper film layer, and can be printed directly on the position to be arranged. In this way, the manufacturing process can not only be simplified, but also the waste of raw ma...

Embodiment 2

[0068] The manufacturing process of LED light board includes the following processes:

[0069] 1) Provide the insulating carrier 1 and the electrical conductor 4, the electrical conductor 4 is fixed on the insulating carrier 1, and the positive and negative lead wires of the electrical conductor 4 respectively penetrate through the end face of the insulating carrier 1;

[0070] 2) Provide conductive ink, and print several groups of conductive ink circuit groups on the end surface of the insulating carrier 1 that is not connected to the transmitter 4, each conductive ink circuit group includes two conductive ink circuits 3, each conductive ink circuit 3 The ends are in contact with the positive and negative leads of the transmitter 4 accordingly;

[0071] 3) Several LED lamps 2 are provided, and when the conductive ink circuit 3 is not dry, several LED lamps 2 are respectively placed in several groups of conductive ink circuit groups, and the lead wires of the two poles of the ...

Embodiment 3

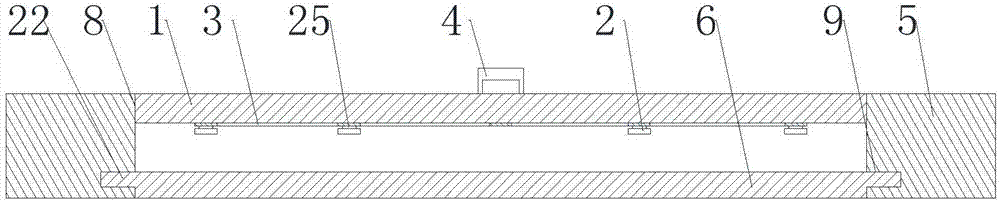

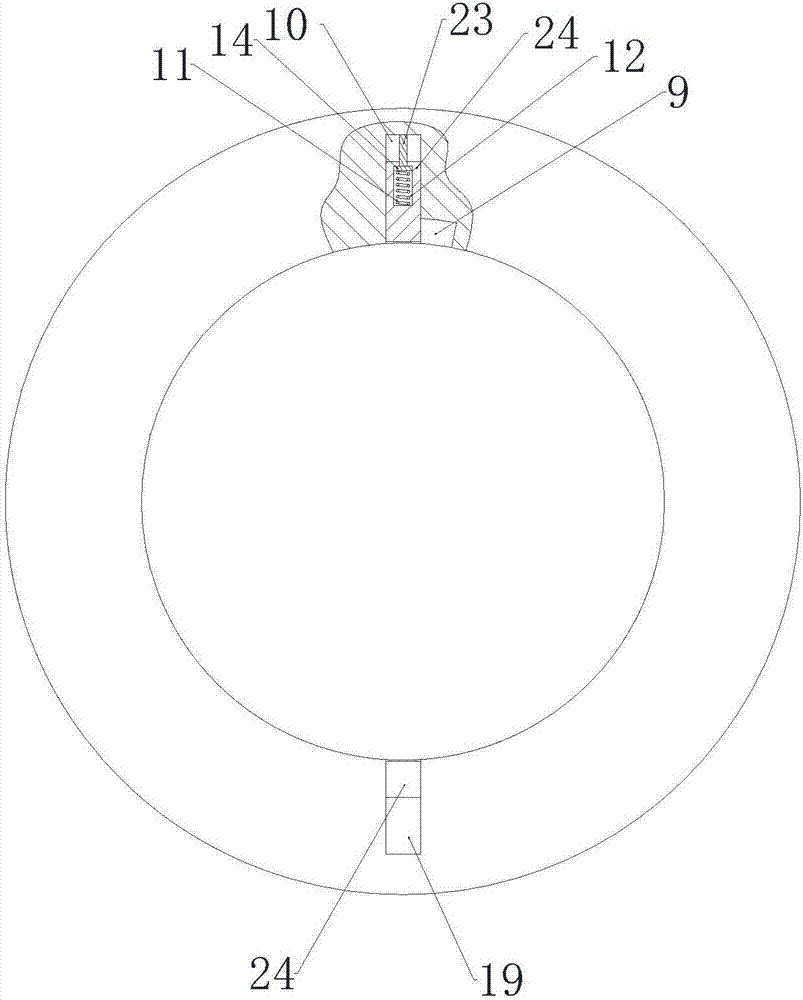

[0076] like figure 2 As shown, the integrated LED lamp for the refrigerator includes a hollow lampshade 5, a light-transmitting plate 6 and an LED lamp board as described in any one of the embodiments;

[0077] The lower end of the lampshade 5 is provided with a first installation port 4 communicating with its inner cavity, and the upper end of the lampshade 5 is provided with a second installation port 8 communicating with its inner cavity;

[0078] The lower end of the lampshade 5 is provided with a concave positioning groove 8 on both sides of the inner wall of the first installation port 4, and the positioning groove 8 communicates with the first installation port 4;

[0079]The lower end of lampshade 5 is also provided with the breach 10 that is all communicated with first installation opening 4 and positioning groove 8 on the both sides of first installation opening 4, and the bottom end of breach 10 runs through the lower end surface of lampshade 5, and breach 10 place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com