Single-phase multi-polar module and single-phase multi-polar module combined switch reluctance motor

A switched reluctance motor, combined technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problem of not being able to reduce mutual inductance between phases, and achieve the effect of reducing mutual inductance between phases and reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

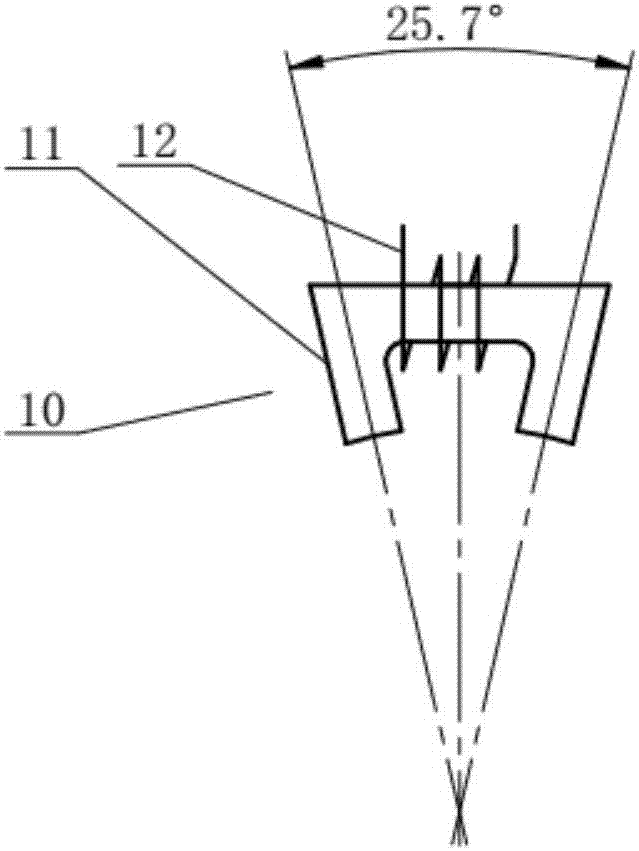

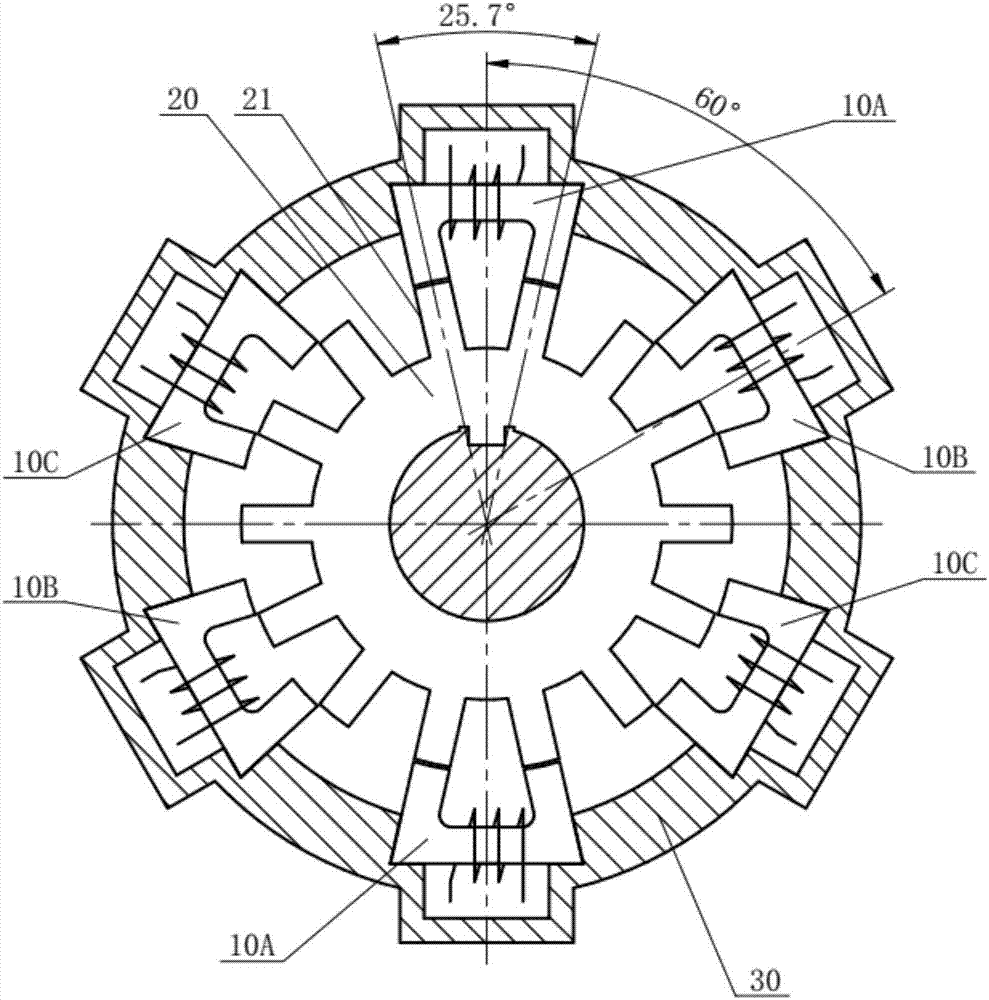

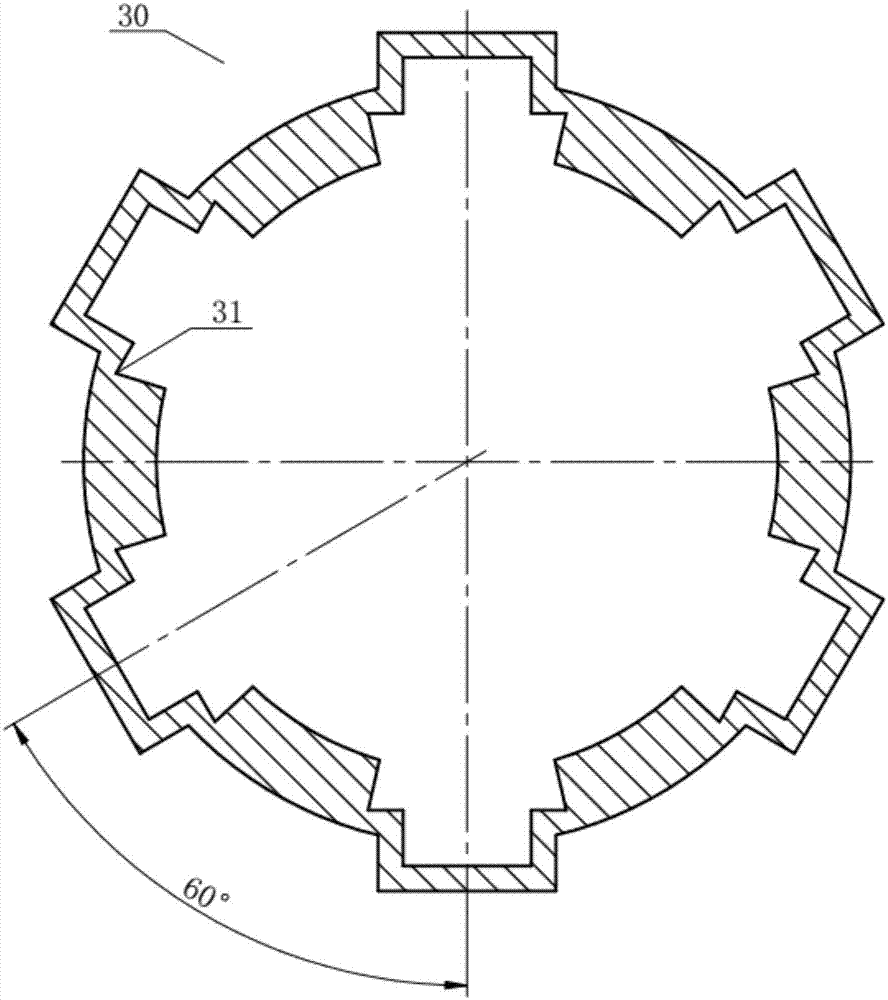

[0035] In order to reduce the phase-to-phase mutual inductance of the reluctance motor, the present invention provides a single-phase multi-pole module combined switched reluctance motor, wherein the single-phase multi-pole module used is such as figure 1 As shown, the single-phase multi-pole module 10 integrates a core module 11 and a single-phase winding 12. The core module 11 is a segmented module of the stator core. The core module 11 includes a salient pole and a yoke connecting the salient poles. The number of salient poles of the iron core module 11 is z, z≥2 and is a natural number, and the figure shows the case where the number of salient poles is 2; the angles between adjacent salient poles of the iron core module are all A; the single-phase winding Wrapped on the salient pole or yoke of the iron core module. The single-phase multi-pole modular combined switched reluctance motor of the present invention includes a rotor iron core, a motor casing, and a motor shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com