DC motor with concentrated winding

A DC motor, concentrated winding technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve problems such as short circuit and complicated winding, achieve simple structure and reduce the risk of short circuit between winding wires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

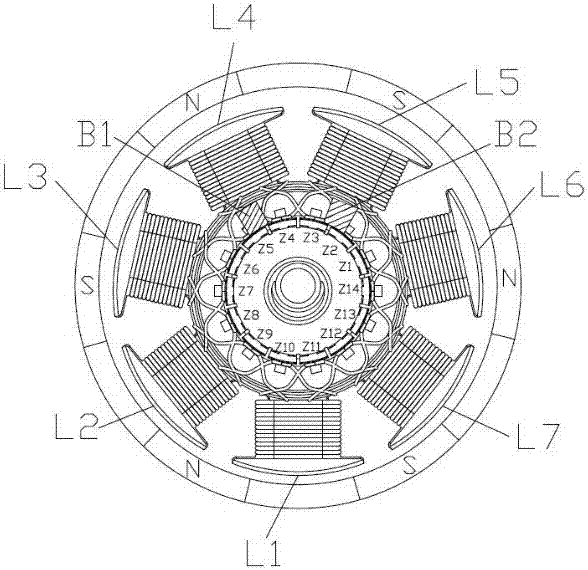

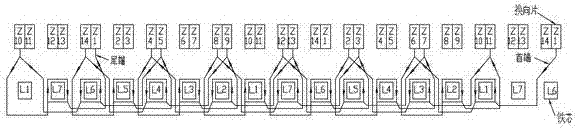

[0013] Depend on Figure 1-2 It can be seen from the illustrated embodiment that this embodiment has a DC motor with concentrated windings, including a stator and a rotor. The stator includes permanent magnet stator poles fixed on the inner wall of the machine base, and also includes a brush B1 connected to the positive pole of the power supply and connected to the power supply. The brush B2 connected to the negative pole; the rotor includes an armature core radially arranged on the rotating shaft, each armature core is wound with an armature winding to form an armature, and a commutator coaxial with the rotating shaft is fixed at one end of the armature core, Each armature core corresponds to two arc-shaped commutator slices, and each commutator slice is fixed on the commutator; when the armature rotates, brush B1 and brush B2 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com