Greenhouse system and greenhouse plantation method

A technology of greenhouse and shed film, which is applied in the field of agricultural engineering, can solve the problems of poor quality of agricultural products, and achieve the effect of improving quality and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

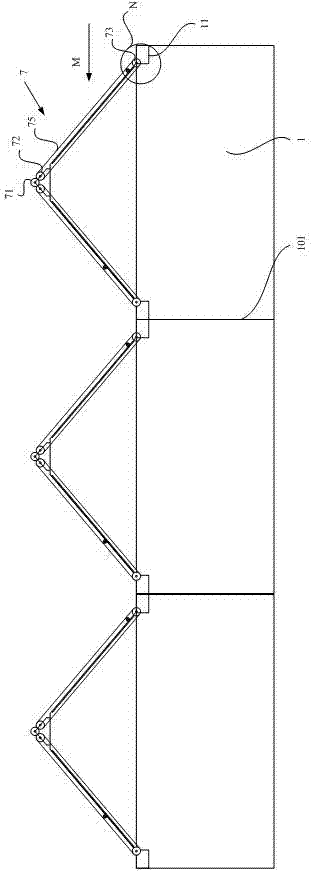

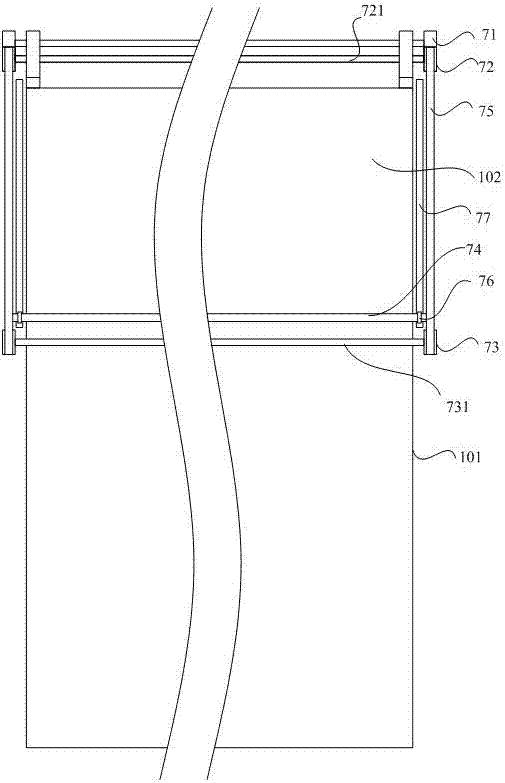

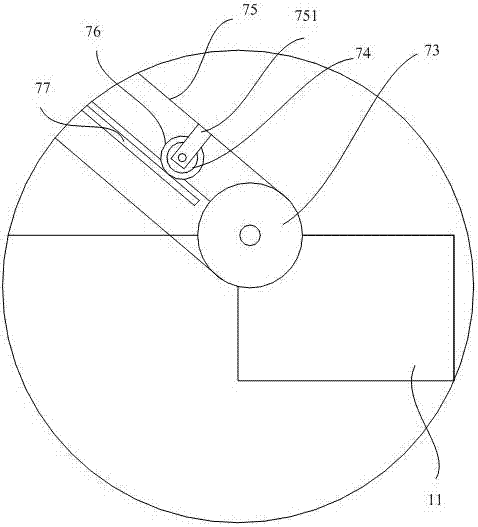

[0033] Such as Figure 1-Figure 3 As shown, the driving mechanism includes a motor 71, two upper synchronous wheels 72 and two lower synchronous wheels 73, an upper synchronous lever 721 is arranged between the two upper synchronous wheels 72, and an upper synchronous lever 721 is arranged between the two lower synchronous wheels 73. A lower synchronous rod 731 is provided, and a synchronous connector 75 is provided between the upper synchronous wheel 72 and the corresponding lower synchronous wheel 73. The synchronous connector 75 is provided with a mounting seat 751, and the mounting seat 751 is A shaft hole is provided, and the film roll shaft 74 is arranged between the two mounts 75 and is rotatably installed in the shaft hole. The rotating part 76 that drives the roll film shaft to rotate, and a matching part 77 for cooperating with the rotating part 76 is also provided between the upper synchronizing wheel 72 and the corresponding lower synchronizing wheel 73; the upper ...

Embodiment 2

[0036] Such as Image 6 As shown, the drive mechanism includes a motor, a rotating shaft 71, a drive chain 72 and a take-up reel 73, the film roll shaft 74 is provided with a rotatable sleeve 741, and one end of the drive chain 72 is connected to the sleeve 741 , the other end of the driving chain 72 is connected to the winding reel 73, the motor 71 is drivingly connected to the rotating shaft 71, the rotating shaft 71 is provided with a driving sprocket 711, and the driving sprocket 711 is connected to the rotating shaft 71. The drive chain 72 is engaged. Specifically, the rotating shaft 71 is located between the film winding shaft 74 and the winding reel 73, and the motor drives the rotating shaft 71 to rotate, so that the driving sprocket 711 pulls the film winding shaft 74 to move through the drive chain 72, thereby cooperating with the rotating part 76 and the matching part 77 , to realize the rotation of the film roll shaft 74. Wherein, the film roll shaft 74 can also ...

Embodiment 3

[0038] Based on the above technical solutions, optional, such as Figure 7-Figure 8 As shown, the greenhouse system of this embodiment also includes a water supply pipe 2, the lower installation surface of the greenhouse 1 is the ground reference plane A, and also includes a water collection container 3; the top of the greenhouse 1 is formed with a plurality of sunken water collection tanks 11 , the water collection tank 11 is respectively connected with the water collection container 3, the water supply pipe 2 is connected with the water collection container 3; the lower edge of the greenhouse 1 is provided with an annular water blocking enclosure 4, and the annular blocking The upper part of the water enclosure 4 is located above the ground reference plane A, the lower part of the annular water blocking enclosure 4 is located below the ground reference plane A, and the water supply pipe 2 is located below the ground reference plane A And lower than the annular water blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com