A new type of grouting anchor

A technology of grouting bolts and bolts, which is applied in the installation of bolts, construction, mining equipment, etc., can solve the problems of reduced reinforcement effect of grouted bolts, insufficient grip, hidden safety hazards, etc., to improve the reinforcement effect , increase the gripping force and overcome frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention are described below in conjunction with:

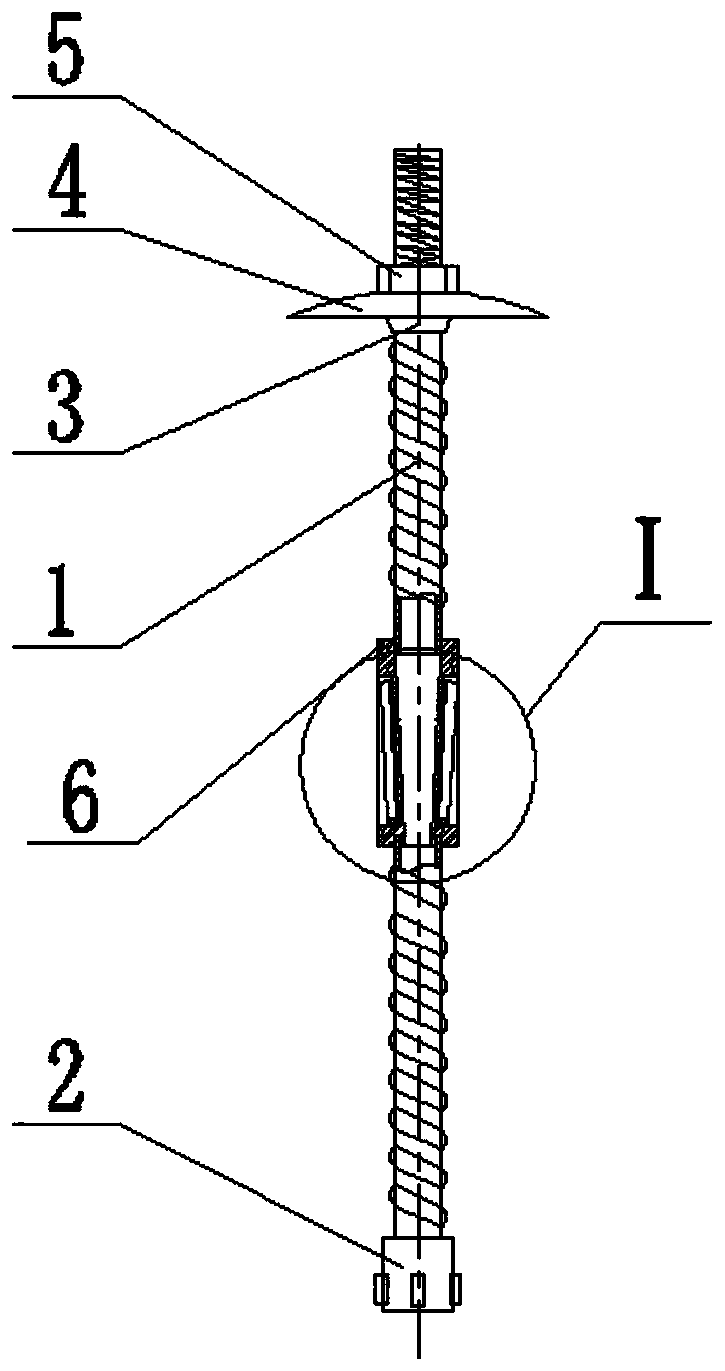

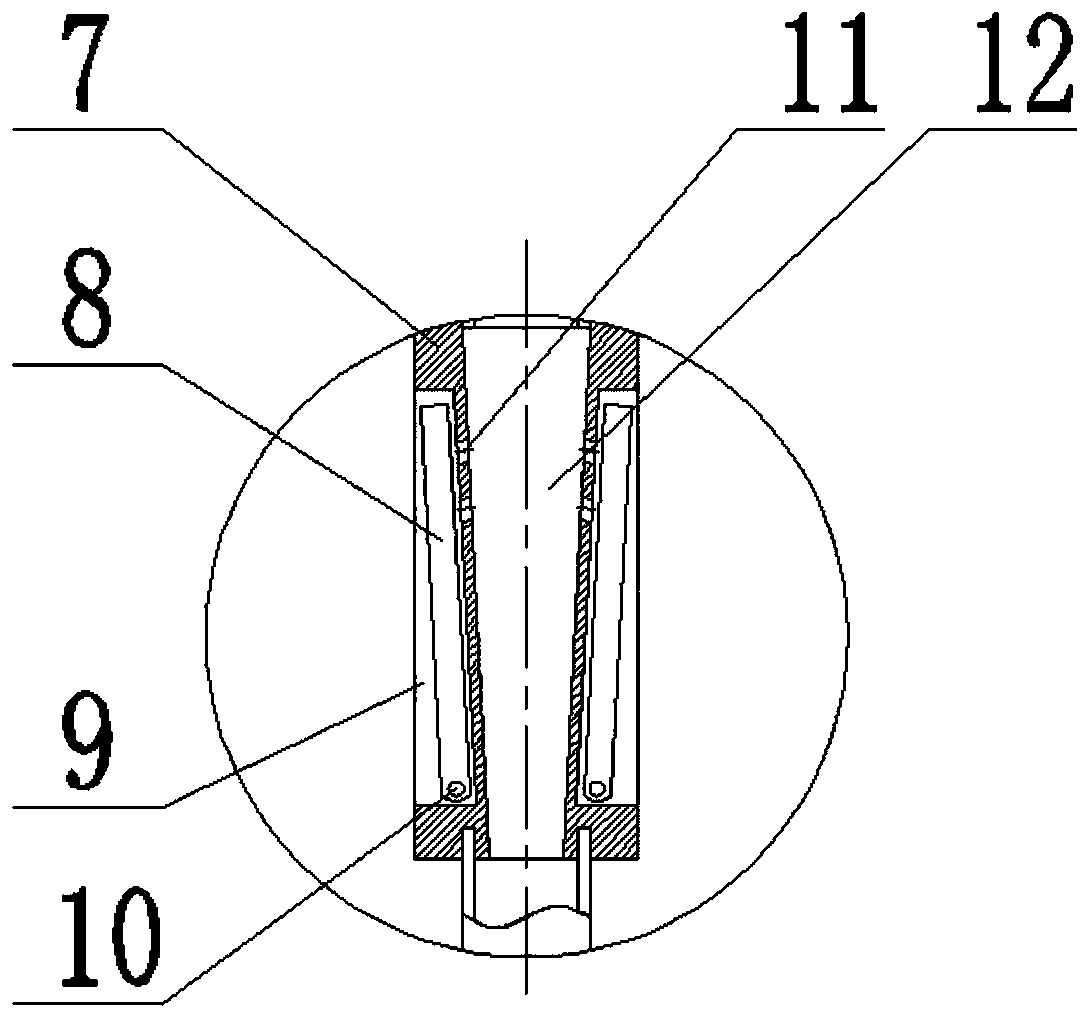

[0018] Such as Figures 1 to 3 As shown, a new type of grouting anchor includes a hollow anchor 1, a drill bit 2 arranged at the front end of the hollow anchor 1, a grout stopper 3 arranged at the rear end of the hollow anchor in turn, an arched supporting plate 4, and a fastening nut 5. It also includes an anchor connection sleeve 6 arranged in the middle of the hollow anchor rod;

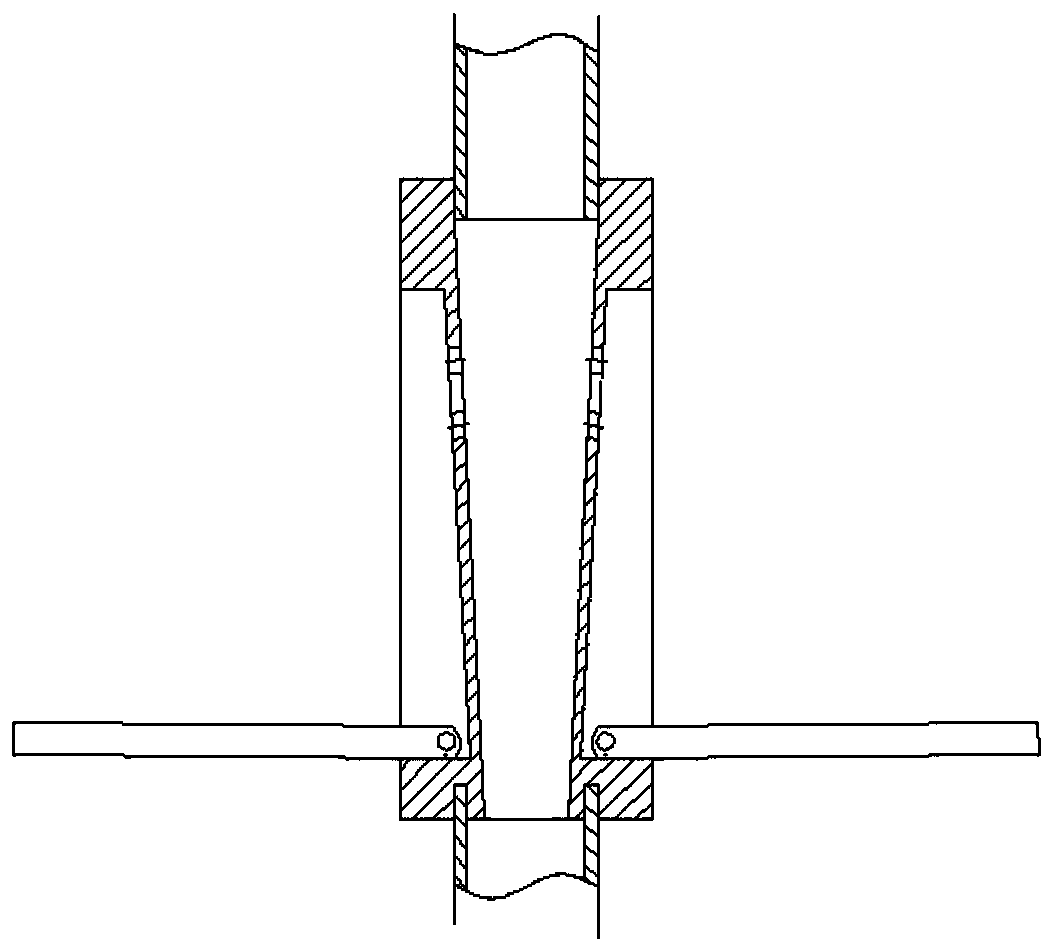

[0019] The anchor connection sleeve 6 includes a cylindrical sleeve 7, and anchor ribs 8 hinged on the cylindrical sleeve 7. The anchor ribs 8 are three in number and evenly distributed on the outer circumference of the cylindrical sleeve 7. Cylindrical sleeve 7 has a groove 9 that is sunken toward its axis, and said groove 9 is compatible with anchor tendon 8, and one end of said anchor tendon 8 is connected to cylindrical sleeve through hinge shaft 10 inside groove 9. The barrel 7 is hinged, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com