Cutting device

A cutting device, cutting fluid technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of maintaining productivity, inability, cutting chips sticking to the workpiece, etc., to prevent halo. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

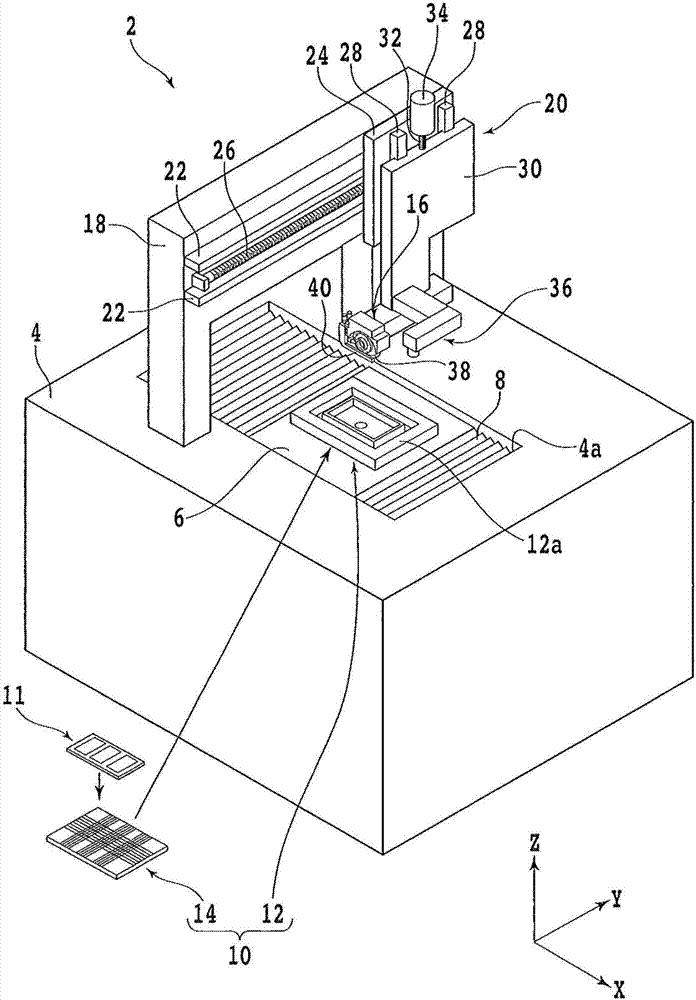

[0020] An embodiment of one aspect of the present invention will be described with reference to the drawings. figure 1 It is a perspective view schematically showing a configuration example of the cutting device of the present embodiment. Such as figure 1 As shown, the cutting device 2 has a base 4 that supports each structure.

[0021] A rectangular opening 4 a long in the X-axis direction (front-rear direction, machining feed direction) is formed on the upper surface of the base 4 . In this opening 4a, an X-axis moving table 6, an X-axis moving mechanism (not shown) for moving the X-axis moving table 6 in the X-axis direction, and a dust-proof and anti-dust mechanism for covering the X-axis moving mechanism are provided. Drop cover8.

[0022] The X-axis moving mechanism has a pair of X-axis guide rails (not shown) parallel to the X-axis direction, and the X-axis moving table 6 is slidably mounted on the X-axis guide rails. A nut portion (not shown) is provided on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com