Dust removing device used for power distribution cabinet, and low-voltage power distribution cabinet

A technology of dust removal device and power distribution cabinet, applied in the field of low voltage power distribution cabinet and dust removal device, can solve the problems of poor dust removal method of low voltage power distribution cabinet, no solution proposed, unfavorable ventilation and heat dissipation, etc., so as to improve the poor dust removal method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

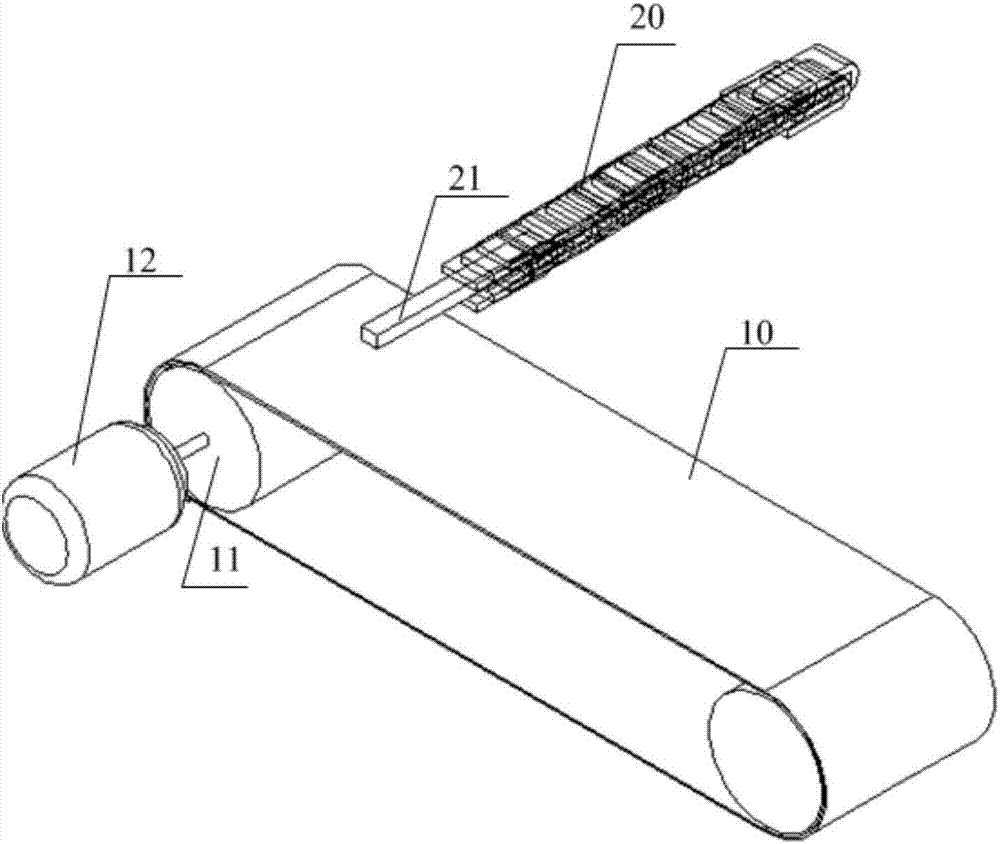

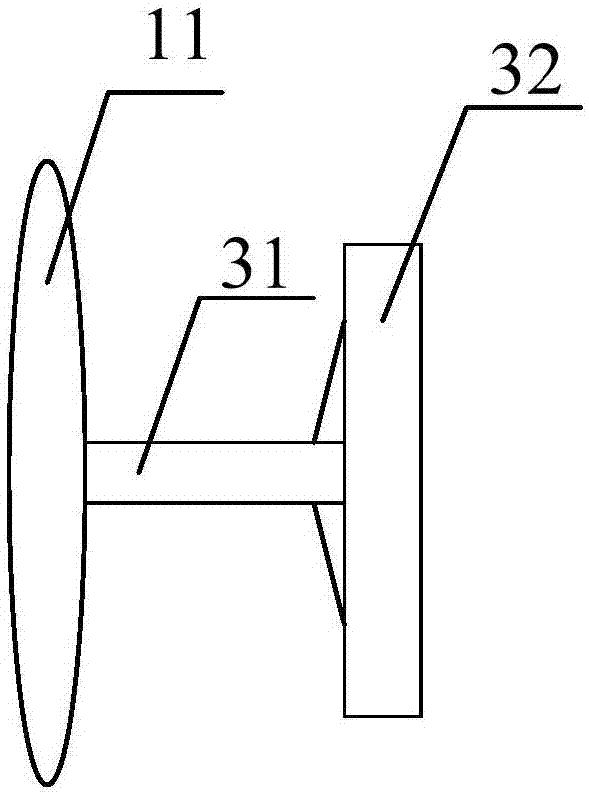

[0043] This embodiment provides a dust removal device for power distribution cabinets, see figure 1 A schematic structural diagram of a dust removal device for a power distribution cabinet is shown, including: a transmission mechanism, a dust removal tool, and a controller; the transmission mechanism includes: a transmission belt 10, a bearing 11 that drives the transmission belt to run, and a motor 12 that drives the bearing to rotate; , the length of the transmission belt is greater than the side length of the ventilation area composed of multiple ventilation holes in the power distribution cabinet; there is also a fixing piece at the center of the bearing to fix the transmission mechanism inside the power distribution cabinet; the motor is also equipped with a motor fixing frame , one end of the motor fixing frame is used to engage the motor, and the other end of the motor fixing frame is used for fixed connection with the power distribution cabinet; the ventilation area is ...

Embodiment 2

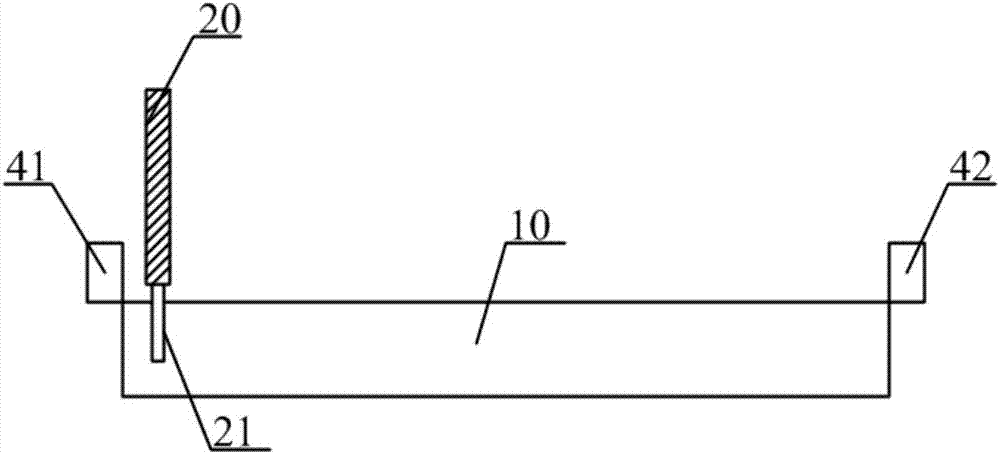

[0056] In the foregoing embodiments, the controller controls the rotation direction, rotation speed and duration of the motor according to the set period and the rotation mode of the motor. This embodiment provides another implementation mode in which the controller controls the operation of the motor , the dust removal device also includes a first contact sensor and a second contact sensor respectively set up at both ends of the transmission belt; the first contact sensor and the second contact sensor are both connected to the controller;

[0057] The first contact sensor is used to send a first signal to the controller when the dust removal tool is touched; the second contact sensor is used to send a second signal to the controller when the dust removal tool is touched;

[0058] The controller is used for controlling the rotation direction of the motor according to the first signal and the second signal.

[0059] For a clear understanding of the positional relationship, see ...

Embodiment 3

[0062] There are many ways to start the dust removal device. The first is to start regularly according to the preset cycle, the second is to start by manual control, and the third is to start automatically according to the dust concentration in the cabinet; the above forms are different. There are unique advantages, which can be used at the same time, or one of them can be selected.

[0063] The first two methods will not be described in detail. In order to enable the dust removal device to realize the third startup method, the dust removal device also includes a dust sensor connected to the controller. The dust sensor is used to collect dust concentration parameters and send the dust concentration parameters to the controller. ; The controller is also used to automatically start the motor to rotate when the dust concentration parameter is greater than the set threshold.

[0064] Through the above method, the dust removal device can remove dust in time to achieve an effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com