Brassica parachinensis harvesting device

A technology for equipment and vegetable moss, which is applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reduced vegetable yield, short-term vegetable moss, lack of goods in the market, etc. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

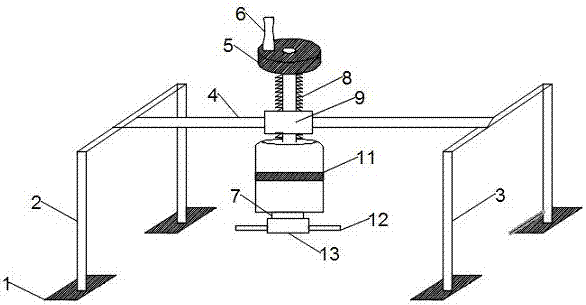

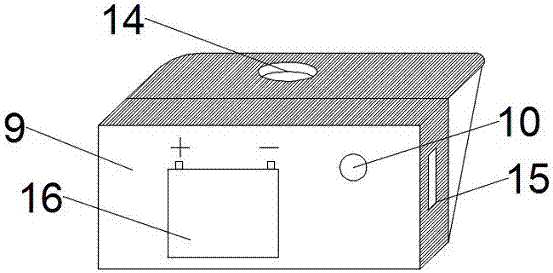

[0019] see figure 1 , figure 2 , the present invention provides a vegetable moss harvesting equipment, comprising a base plate 1, a support frame I2 is provided on the base plate 1, a crossbeam 4 is provided at the middle position of the support frame I2, and a support frame II3 is provided at the right end of the crossbeam 4, Because the structure, size, and material of the support frame I2 and the support frame II3 are completely consistent, and they are all made of plastic, the equipment is light in weight and easy to carry. Drive screw mandrel 8 is arranged, and the upper end of drive screw mandrel 8 is provided with rotating disc 5, is provided with rocking handle 6 at the edge place of rotating disc 5, and motor 11 is installed at the lower end of drive screw mandrel 8, because slide block 9 can not only Ensure that the motor 11 can move laterally, and cooperate with the crank handle 6 to make the motor 11 move up and down. At the same time, the beam 4 is embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com