Buckwheat deep and shallow row sowing machine and sowing weed prevention method thereof

A seeder, deep and shallow technology, applied in planting methods, sowing seeders, excavation/covering trenches, etc., can solve the problems of insufficient rainwater during the sowing period, many weeds between the ridges, and inability to sow at the right time. Row farming, promoting reproductive and vegetative growth, ensuring timely harvesting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

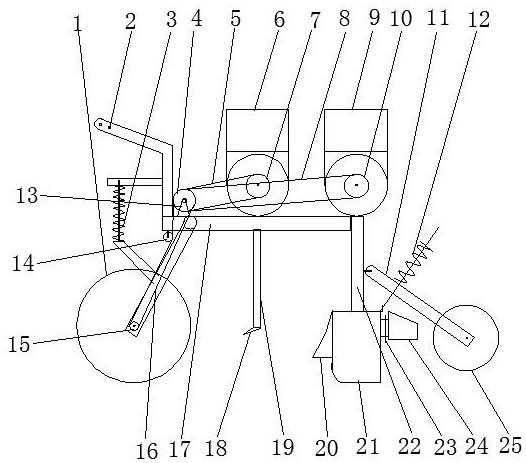

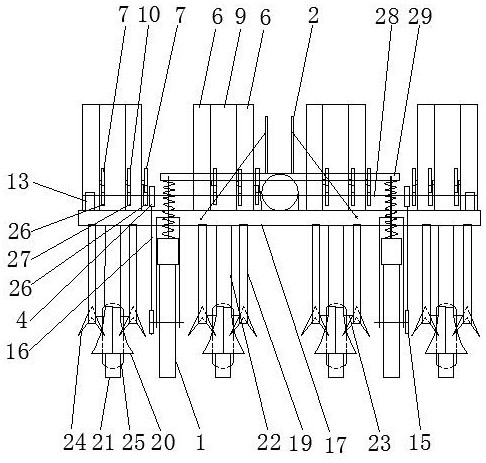

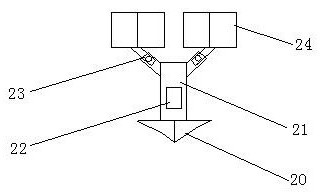

[0017] The present invention will be further described below with reference to the accompanying drawings.

[0018] Such as figure 1 , 2 As shown, the buckwheat depth of the present invention includes a frame 17, a traction rod 2, a support wheel 1, a cushioning spring one, a traction cable 29. The shaft side of the support wheel 1 is provided with a drive sprocket 15, and the front portion of the frame 5 is provided with the drive shaft bearing housing 13 and the drive shaft 28, and the rear portion on the rack 5 is provided with a shallow cell seeding assembly 6 and Deep Sencher Assembly 9, the proportion of shallower seeder assembly 6 and the deep sower assembly 9 is 2: 1, the rear support of the frame 5 and the function of the deep seed tube 22 are one, The middle of the rear side of the deep seed tube 22 is hinged in the middle. The drive sprocket 15 is connected to the drive chain 16 and the drive chain 16 by the rising wheel 14 to regulate the tightness. A plurality of shall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com