A steam-assisted wet nanofiltration membrane membrane preparation method and bottom membrane preparation method

A nanofiltration membrane and wet process technology is applied in the field of separation membrane composite material preparation, which can solve the problems of unreported nanofiltration membranes, and achieve the effects of high repeatability, good water flux and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

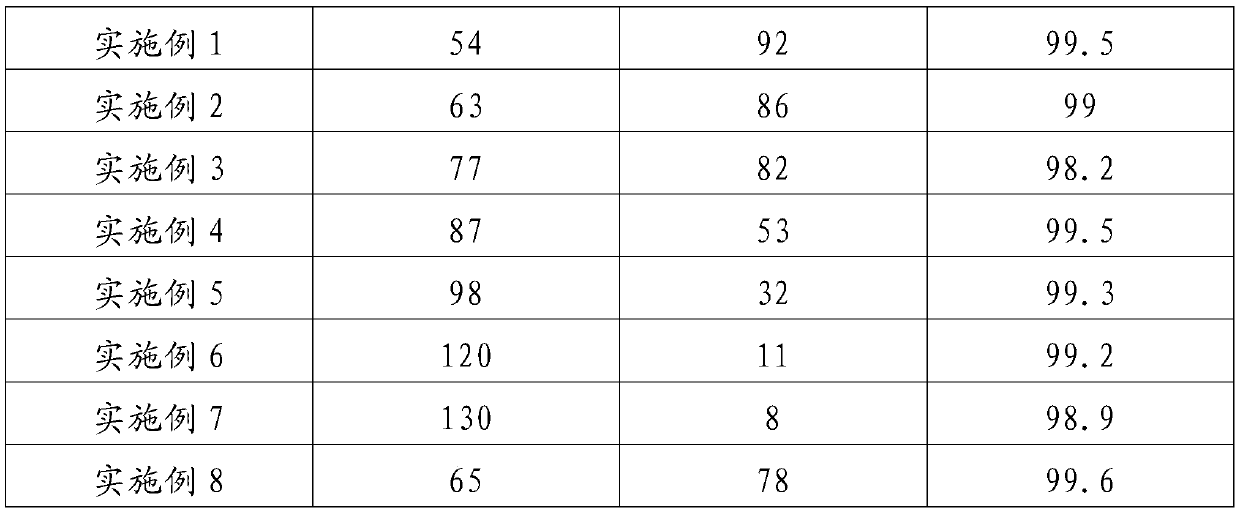

Embodiment 1

[0032] The invention discloses a steam-assisted wet nanofiltration membrane manufacturing method, which is realized according to the following steps:

[0033] (1) Preparation of ultrafiltration polysulfone base membrane

[0034] Evenly coat the polysulfone DMF solution with a solid content of 13% in terms of mass fraction on the non-woven fabric substrate, then quickly immerse the non-woven fabric in pure water, let it stand for 1min, take it out, and then put it in 70°C water 1min, take it out and put it in pure water for later use;

[0035] (2) Immerse the polysulfone ultrafiltration membrane in the m-phenylenediamine solution with a mass fraction of 2.5% for 3 minutes, remove the excess water phase with an air knife, and then use a slit coater to coat the surface with a mass fraction of 0.11%. ISOPAR G solution of trimesoyl chloride; coating thickness is 60 μm;

[0036] (3) The temperature of the above-mentioned coated polysulfone ultrafiltration membrane is 100°C, the ab...

Embodiment 2

[0038] The invention discloses a steam-assisted wet nanofiltration membrane manufacturing method, which is realized according to the following steps:

[0039] (1) Preparation of ultrafiltration polysulfone base membrane

[0040] Apply the polysulfone DMF solution with a solid content of 20% by mass fraction evenly on the non-woven fabric substrate, then quickly immerse the non-woven fabric in pure water, let it stand for 1min, take it out, and then put it in 70°C water 1min, take it out and put it in pure water for later use;

[0041] (2) Immerse the polysulfone ultrafiltration membrane in the m-phenylenediamine solution with a mass fraction of 2.5% for 3 minutes, remove the excess water phase with an air knife, and then use a slit coater to coat the surface with a mass fraction of 0.11%. ISOPAR G solution of trimesoyl chloride; coating thickness is 60 μm;

[0042] (3) The temperature of the above-mentioned coated polysulfone ultrafiltration membrane is 100°C, the absolute h...

Embodiment 3

[0044] The invention discloses a steam-assisted wet nanofiltration membrane manufacturing method, which is realized according to the following steps:

[0045] (1) Preparation of ultrafiltration polysulfone base membrane

[0046] Evenly coat the polysulfone DMF solution with a solid content of 13% in terms of mass fraction on the non-woven fabric substrate, then quickly immerse the non-woven fabric in pure water, let it stand for 1min, take it out, and then put it in 70°C water 1min, take it out and put it in pure water for later use;

[0047] (2) Immerse the polysulfone ultrafiltration membrane in the m-phenylenediamine solution with a mass fraction of 2.5% for 3 minutes, remove the excess water phase with an air knife, and then use a slit coater to coat the surface with a mass fraction of 0.11%. ISOPAR G solution of trimesoyl chloride; coating thickness is 60 μm;

[0048] (3) Send the above-mentioned coated polysulfone ultrafiltration membrane into the air at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com