Oscillation cross section adjustable oscillator

An adjustable, oscillator technology, applied in shaking/oscillating/vibrating mixers, chemical instruments and methods, dissolution, etc., can solve problems such as poor oscillation of the vibrating frame, long oscillation time, and increased sliding resistance, and achieve Improve the homogenization efficiency of oscillation, improve the uniformity of oscillation, and increase the effect of oscillation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

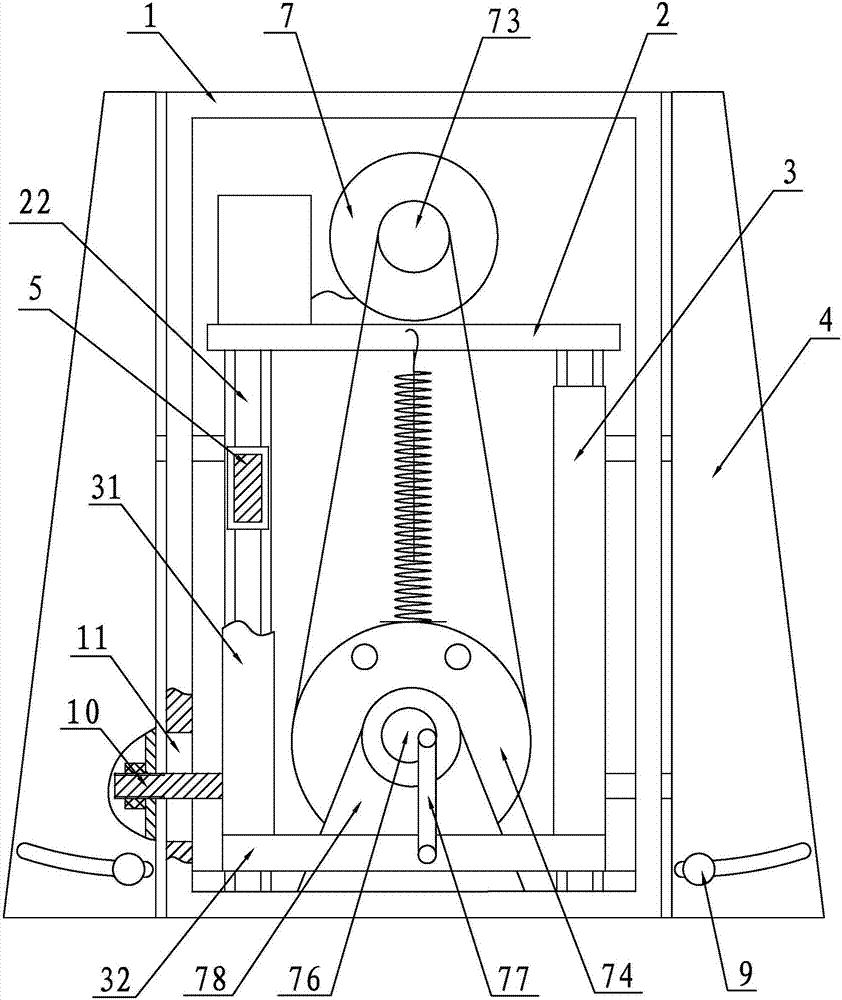

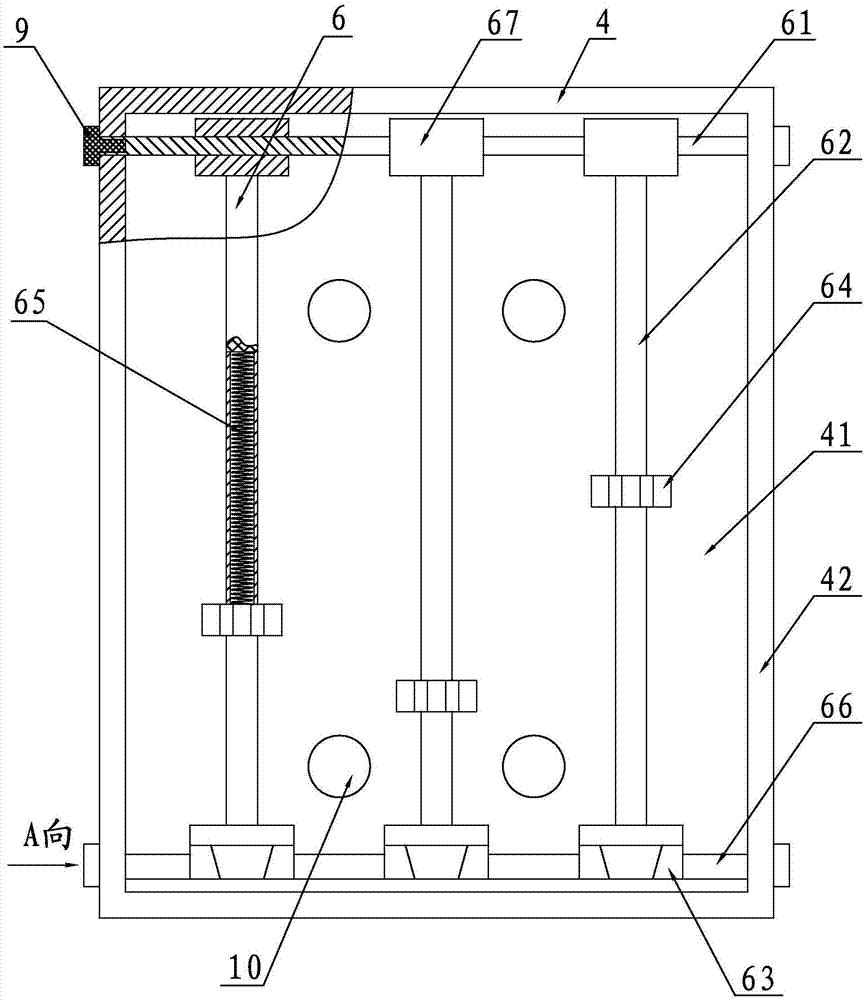

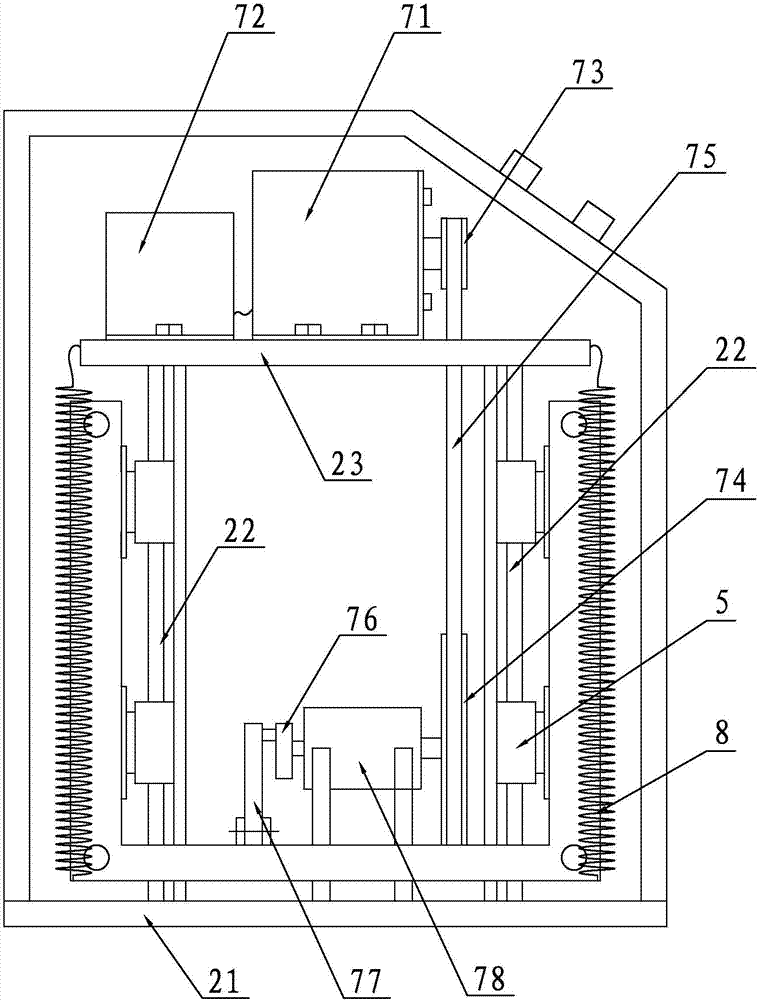

[0034] Embodiment 1: an oscillator with adjustable oscillation section, such as Figure 1 to Figure 6As shown, it includes a chassis 1, a fixed frame 2, an oscillating bracket 3, an oscillating box 4, a guide slider 5, a separating funnel positioning device 6, an oscillation generating mechanism 7 and a return spring 8, and the fixed frame 2 consists of a base 21, four A guide rail 22 and a fixed platen 23 are formed, and four guide rails 22 are fixed between the base 21 and the fixed platen 23 according to a rectangular distribution scheme, and the oscillation support 3 includes four vertical rods 31 and a rectangular bottom frame 32, two guide sliders 5 are fixed at intervals along the height direction on each vertical rod 31, and the guide sliders 5 are slidably set on the corresponding guide rails 22, and the oscillation generating mechanism 7 includes a motor 71 , frequency conversion regulator 72, driving wheel 73, driven wheel 74, belt 75, eccentric wheel 76, rocker lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com