Potato pulverizer taker-in roller

A mill and licker-in technology, applied in grain processing and other directions, can solve the problems of high manufacturing cost, difficult operation, high cost, etc., and achieve the effects of simplifying production and processing steps, reducing production and processing difficulty, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

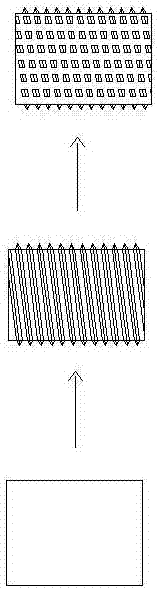

[0014] Combine below figure 1 , figure 2 and image 3 , to further illustrate the technical solution of the present invention.

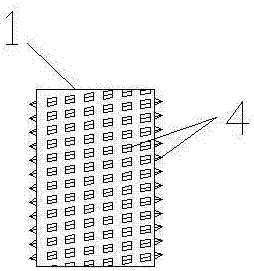

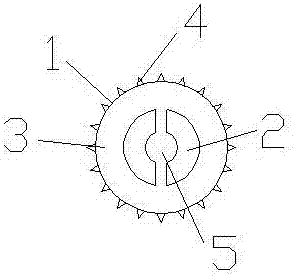

[0015] A potato mill licker-in roller, comprising a cylindrical roller body 1, the roller body 1 includes a hollow part 2 and an outer ring part 3 wrapping the hollow part 2, and the outer peripheral surface of the outer ring part 3 is regularly distributed with Spikes 4.

[0016] The height of the pointed protrusion 4 is 2-5 mm, and the thickness of the outer ring part 3 is 8-20 mm. The thickness of the outer ring part 3 is less than the four parts of the pointed protrusions 4, which can be processed many times to ensure the service life of the licker-in roller.

[0017] The pointed protrusions 4 are evenly distributed in multiple rows along the axial direction of the roller body 1 , and the pointed protrusions 4 on two adjacent rows of pointed protrusions 4 are alternately arranged. The distribution density and arrangement shape of the pointe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com