Self-cleaning lotus-shaped fire spraying device

A flame-throwing device and self-cleaning technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve problems such as inconvenient maintenance, difficult maintenance and repair, and failure to work normally, so as to achieve convenient maintenance, increase stability and service life, beautiful fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

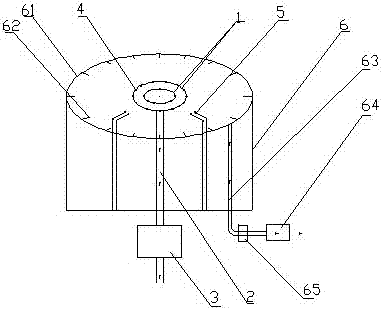

[0014] As shown in the figure: a self-cleaning lotus-shaped fire injection device, including two circular fuel gas pipes 1, fuel intake manifold 2, high-pressure gasification device 3, multiple fire spray nozzles 4, igniter 5, nozzle cleaning Mechanism 6, the flame spray nozzle 4 is evenly arranged on the annular fuel gas pipe 1, forming a sprayed flame in a lotus shape, the annular fuel gas pipe 1 communicates with the fuel intake main pipe 2, and the fuel intake main pipe 2 The above-mentioned high-pressure gasification device 3 is provided on it, and the nozzle cleaning mechanism 6 includes an annular water pipe 61, a plurality of high-pressure water guns 62, a high-pressure water inlet main pipe 63, a high-pressure water pump 64, and a solenoid valve 65. The annular water pipe 61 Set on the periphery of the annular fuel gas pipe 1, the high-pressure water gun 62 is evenly arranged on the annular water pipe 61, the direction of the gun head corresponds to the fire nozzle 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com