Injection device based on dual piezoelectric actuators

A spraying device and actuator technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low dispensing frequency and slow speed, and achieve high work efficiency, large driving force and accurate displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, the present invention will be further described in detail with specific embodiments with reference to the accompanying drawings.

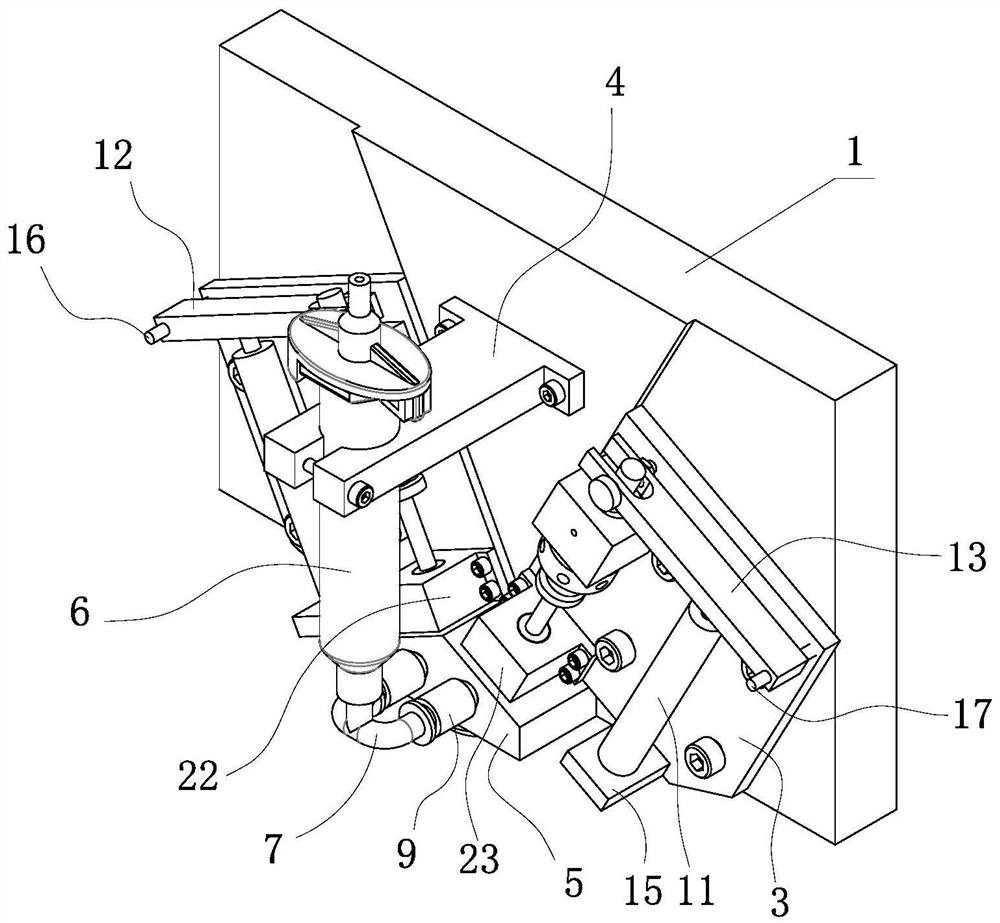

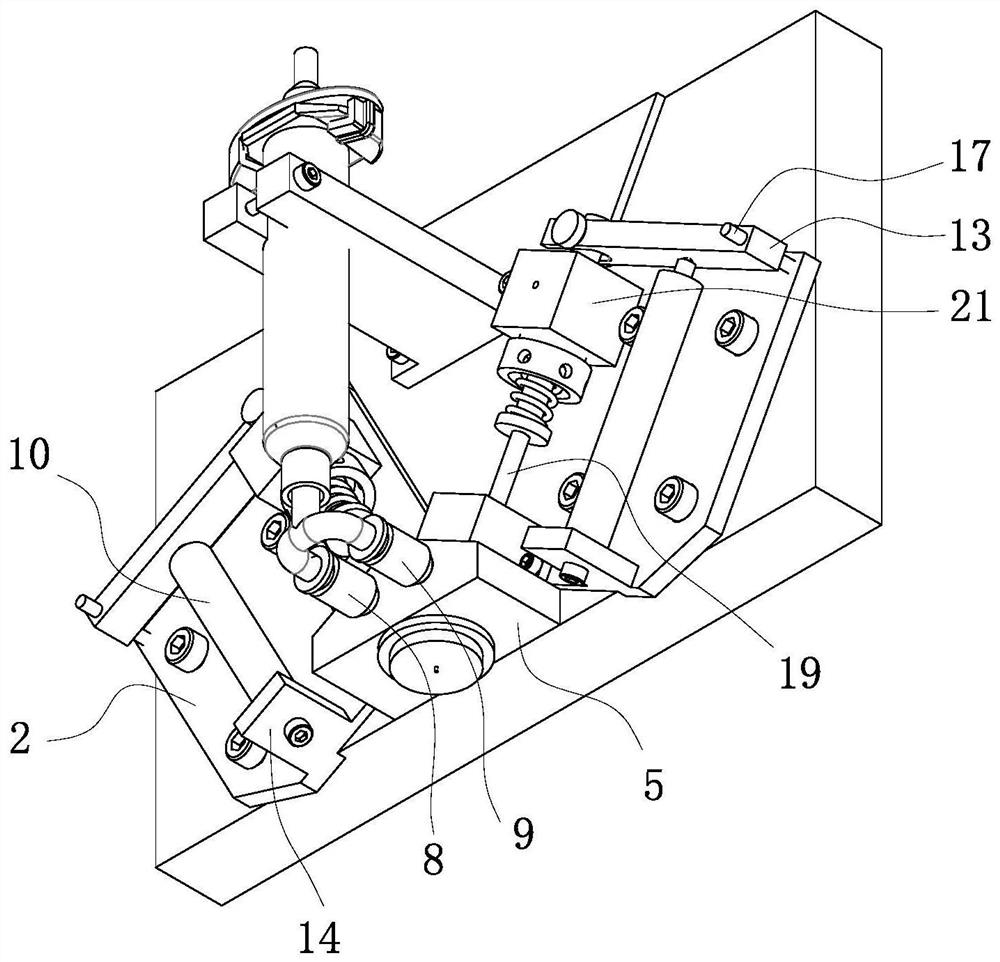

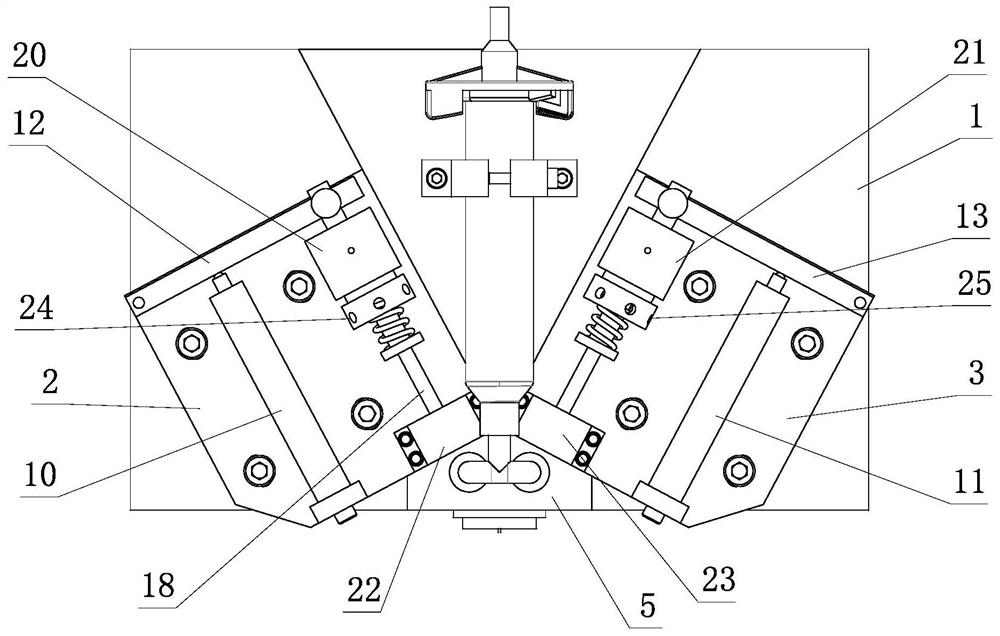

[0060] like Figure 1-7 , 15, the injection device based on dual piezoelectric actuators includes a rear seat 1, a left support plate 2, a right support plate 3, a rubber storage cylinder bracket 4, a triangular nozzle valve 5, a rubber storage cylinder 6, a rubber guide tube 7, Left joint 8, right joint 9, left piezoelectric ceramic actuator 10, right piezoelectric ceramic actuator 11, left link 12, right link 13, left shaft 16, right shaft 17, left striker 18, right striker 19. Upper left end cap 20, upper right end cap 21, lower left end cap 22, lower right end cap 23, left adjustment nut 24, right adjustment nut 25, left spring 26, right spring 27, upper left linear bearing 30, lower left linear bearing 31, The upper right linear bearing 32 and the lower right linear bearing 33 are provided.

[0061] The left support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com